Main content:

In recent years, with the rapid and vigorous development of new energy vehicles, power battery technology and related integrated management technologies have emerged in an endless stream. Such as new material technology, new process technology, new integration technology, new management technology, etc. bring together the latest R & D and application achievements of material factories, lithium battery companies in the world and vehicle factories. This article organizes and briefly introduces top 10 battery pack integration technologies and management technologies in China.

1. Traditional battery pack integration technology

The most traditional battery pack integration technology is CTM (Cell To Module). First, several battery cells are connected in series and parallel to form a module, then the module is assembled into the battery pack, and finally the battery pack is integrated into the car chassis. Under the CTM structure, the battery cells are better protected by structural parts such as modules, the battery pack has high strength, and the difficulty of grouping is small.

However, the space utilization rate of batteries assembled into modules is 80%, the space utilization rate of modules integrated into battery packs is 50%, and the space utilization rate of final batteries integrated into battery packs is only 40%. With the rapid popularization of new energy vehicles and the extreme development of lithium-ion battery performance, at the battery application level, the integration efficiency of battery packs needs to be improved urgently, and large-scale modularization, de-modularization, and body integration technologies have become mainstream trends.

2. Top 10 battery pack integration technologies

① CTP of CATL

In September 2019, CATL officially released the world's first CTP (Cell To Pack) battery pack, which will be equipped on BAIC's EU5 models. Compared with the traditional battery pack, the volume utilization rate of the battery pack using the new CTP technology is increased by 15%~20%, the number of parts is reduced by 40%, the production efficiency is increased by 50%, and the system cost is reduced by 10%.

In terms of energy density, the CTP battery pack can be as high as 200Wh/kg, which is more than 30% higher than the traditional structure, which can greatly improve the battery life of electric vehicles. CTP technology in top 10 battery pack integration technologies includes two ideas: one is large modularization, and the other is non-modularization. The CTP released by CATL this time is a large-scale modularization technology. Its core logic is to increase the capacity of a single battery cell, and at the same time stack multiple batteries to form a larger battery module.

Thereby greatly reducing the number of modules and parts, thereby achieving the goals of energy density improvement and cost reduction. In addition to using large batteries to form large modules, as one of the top 10 battery pack integration technologies in China, CTP technology usually optimizes the connection structure between modules, reduces parts and simplifies the assembly process.

Although the CTP battery pack has the advantages of strong applicability, high space utilization, low cost, and good heat dissipation performance, due to the barrel effect, the overall performance of the battery pack will depend on the performance of the worst battery cells that make up the battery pack. Therefore, the CTP structure puts forward higher requirements on the consistency of the battery cells. In addition, if the battery fails and needs to be replaced, the convenience and cost of maintenance are higher.

② CTC of Tesla

In 2020, Tesla announced the CTC (Cell To Chassis) technology for the first time. The CTC integration technology in top 10 battery pack integration technologies combined with the front and rear body integrated die-casting technology can reduce about 370 parts, reduce the body weight by 10%, and reduce the battery cost per kWh by 7%. CTC technology eliminates the two assembly processes from battery cell to module and then to battery pack, and directly integrates the battery into the chassis of the vehicle body.

The essence of CTC technology is to combine the upper shell of the battery pack and the lower floor of the vehicle body into one, and the seat is directly installed on the upper cover of the battery pack. The battery pack is not only an energy supply device, but also a structural component of the vehicle. The advantages of CTC technology in top 10 battery pack integration technologies in China are obvious. Since the two-level assembly process of "module" and "battery pack" is skipped, the battery is directly integrated into the body floor, which will greatly save space, or more batteries can be accommodated in the same space, thereby improving battery life.

At the same time, parts and structural parts are also greatly reduced, which reduces weight, simplifies the process, and saves costs. The glue filling solution "turns parts into wholes" for the battery and greatly improves the rigidity of the body. However, the shortcomings of the CTC structure are also very prominent. On the one hand, it puts forward high requirements on the consistency of the single battery. On the other hand, since the battery is integrally integrated in the body floor and glued to each other, it is almost impossible to repair and the repair cost is extremely high.

③ JTM of GOTION HIGH-TECH

On January 8, 2021, GOTION HIGH-TECH released the 210Wh/kg lithium iron phosphate pouch cell and JTM (Jelly Roll To Module) battery technology. It is said that the use of JTM integration technology can increase the efficiency of module assembly to more than 90%, with its high specific energy lithium iron phosphate battery. It can achieve a module energy density of nearly 200Wh/kg and a system energy density of 180Wh/kg, exceeding the level of the NCM622 ternary system and meeting the battery life and car battery voltage requirements of high-end passenger cars.

Among the top 10 battery pack integration technologies, the biggest difference between JTM and other battery integration technologies is that other integration technologies are based on batteries as the smallest unit. JTM batteries parallel and connect single winding cores inside the aluminum shell, reducing the number of external connectors, resulting in higher energy density and lower cost. Moreover, the process is simple, easy to form standardization, and each single winding core can be independent of each other, and will not spread to each other when thermal runaway occurs, which further delays the occurrence of thermal runaway and improves battery safety performance.

④ GAC Aion's magazine battery

On March 10, 2021, GAC Aion released the world's first first-generation magazine battery system safety technology. Because it adopts a design similar to the magazine safety cabin, it is called "magazine battery" for short. For the first time in the industry, the whole package of ternary lithium battery can not catch fire after acupuncture, claiming to redefine the active safety standard of ternary lithium battery. By optimizing the design and production process, the volumetric energy density of the system is increased by 9.4% (302Wh/L), the mass energy density of the system is increased by 5.7% (185Wh/kg), and the cost is reduced by 10%.

It is reported that the magazine battery technology in the top 10 battery pack integration technologies is based on the design idea of "preventing short circuit in the cell, preventing thermal runaway after short circuit, and preventing heat spread after thermal runaway", mainly including four core technologies:

- Ultra-high heat-resistant and stable batteries

- Super heat-insulated battery safety compartment

- Extremely fast cooling three-dimensional rapid cooling system

- Full-time control of the fifth-generation battery management system

As one of the top 10 battery pack integration technologies, the magazine battery has been upgraded through safety technology, so that the whole pack of ternary lithium battery does not catch fire. It plays an important role in promoting the application of ternary lithium batteries in new energy vehicles, and solves the safety problem of ternary lithium batteries at the system level.

⑤ DFAC "three no" battery

On March 17, 2021, DFAC demonstrated for the first time the safety technology of the battery pack, car body structure, and electrical system of Lantu FREE (pure electric version), and gave a comprehensive interpretation of the safety technology of the battery pack. The ternary lithium battery pack has the characteristics of high energy density, good low temperature performance, and good rate performance, but the corresponding thermal stability is worse, and better safety protection and thermal management are required.

Both high energy and high safety must be met, which poses a great challenge to battery technology. However, among the top 10 battery pack integration technologies in China, Lantu FREE uses ternary lithium batteries as the power system, but it can achieve the whole package "no smoke, no fire, no explosion", which is called "three no" batteries by the media, which means that the system safety of ternary lithium batteries Technology has risen to a new level.

⑥ Dayu battery of Great Wall Motor

On June 29, 2021, Great Wall Motors officially released the "Dayu Battery". According to reports, the Dayu battery was named mainly because its safety and security principles adopted Dayu's concept of water control. The battery safety is guaranteed from the PACK level by adopting a multi-stage commutation system, a fast extreme cold suppression system, a multi-stage directional explosion-discharge system, and a fire extinguishing box system. Dayu batteries, one of the top 10 battery pack integration technologies in China, use high-nickel 811 ternary materials, and thermal runaway is caused by heating.

The highest temperature in the experiment exceeded 1000°C, but there was no fire and explosion throughout the process, and the temperature of the smoke exhausted by Dayu batteries was lower than 100°C. It is understood that Dayu Battery mainly improves the safety performance of the ternary lithium battery package from eight aspects: heat source isolation, two-way commutation, heat flow distribution, directional explosion discharge, high temperature insulation, automatic fire extinguishing, positive pressure oxygen resistance, and intelligent cooling.

⑦ MTC

On April 25, 2022, Leapmotor disclosed its latest CTC technology for the first time (Leapmotor officially announced CTC, strictly speaking it should be MTC, or Module To Chassis). It is reported that Leapmotor's MTC chassis integration technology in top 10 battery pack integration technologies can reduce the number of parts by 20%, reduce the cost of structural parts by 15%, increase the battery layout space by 14.5%, increase the vertical space of the body by 10mm, and increase the battery life under comprehensive working conditions by 10%.

This technology will be the first to be mass-produced and applied in the Leapmotor pure electric vehicle C01, with a cruising range of 700km. Compared with Tesla's CTC technology, Leap Motor MTC seems to be a compromise technology. Since the module structure is not canceled, there is still room for improvement in terms of integration efficiency and cost.

And because the upper cover of the traditional battery pack is cancelled, the threat to the passenger compartment is greater when the battery heat is out of control. However, since the battery tray is easy to disassemble, when maintenance is required, the body floor and seats do not need to be disassembled, which is more convenient and faster, and it is a feasible mass production technology.

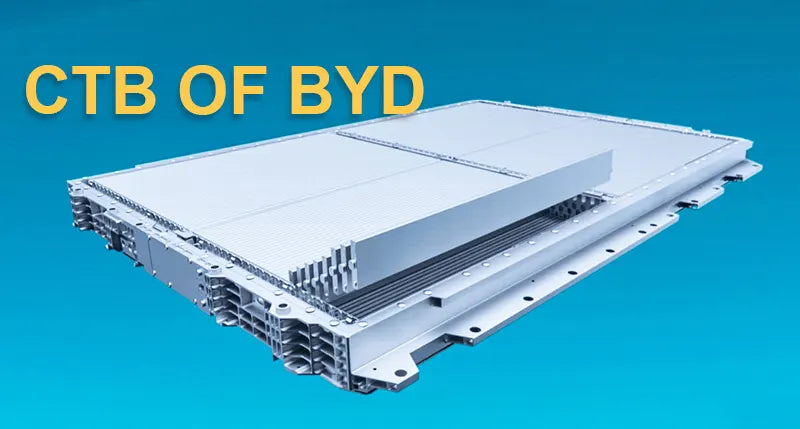

⑧ CTB of BYD

On May 20, 2022, BYD launched the world's first CTB body integration technology and the e-platform 3.0 pure electric vehicle equipped with CTB technology - seal. According to reports, after the seal is equipped with CTB technology, the utilization rate of its power battery system is increased by 66%, the energy density of the system is increased by 10%, and the cruising range of 700km can be achieved.

Its power battery still uses a blade battery, which can achieve the fast charging capability of charging for 15 minutes and driving 300km. Among the top 10 battery pack integration technologies in China, the CTB technology still adopts the array arrangement of blade batteries, which has excellent safety performance, and the battery pack cover and battery tray sandwich the blade batteries in the middle, forming a honeycomb-like structure.

According to the test video released by BYD, the battery compartment can withstand the crushing of a 50t heavy truck and can continue to be used after being put back into the body. The advantages of CTB technology are high safety, high strength, light weight, and low cost. Its maintainability is slightly better than Tesla's CTC technology in top 10 battery pack integration technologies, but its integration is more conservative than CTC technology.

⑨ ONE PACK of SAIC

On June 13, 2022, the MG brand of SAIC Passenger Vehicles released the "ONE PACK" for the first time, and unveiled the first model equipped with ONE PACK - MG MULAN. According to reports, As one of the top 10 battery pack integration technologies in China, ONE PACK uses a standard battery pack with a length of 1690mm, a width of 1300mm, and a height of 110mm, 125mm and 137mm. Since the length and width are fixed, the needs of different cruising ranges can be realized only by changing the height.

Since the battery pack has the same length and width, the Rubik’s Cube battery also adopts a unified battery cell fixing position, a unified quick-change cooling interface, and a unified high-voltage and low-voltage interface, which means that the Rubik’s Cube battery can realize the power exchange function. The biggest technical feature of ONE PACK in top 10 battery pack integration technologies is the arrangement of lying batteries, while traditional battery packs are arranged vertically or sideways. The layout of lying batteries makes the layout of the whole vehicle more efficient, with longer cycle life and better safety performance.

⑩ Kirin Battery of CATL

On June 23, 2022, CATL officially released the third-generation CTP battery pack technology - Kirin battery. Through the structural improvement of the battery pack, the space utilization rate was increased from 56% to 72%. Its system energy density can reach 255Wh/kg, which is 13% higher than that of Tesla, and the cruising range of the whole vehicle can easily exceed 1000km. Adopting the world's first large-surface cooling technology, the Kirin battery in top 10 battery pack integration technologies supports 5-minute fast hot start and 10-minute fast charging to 80% SOC, achieving comprehensive improvements in battery life, fast charging, safety, life, efficiency, and low-temperature performance.

According to the CATL report, as a battery pack technology in top 10 battery pack integration technologies, the Kirin battery can achieve 4C fast charging technology, which can achieve hot start in 5 minutes and fast charging to 80% in 10 minutes. In addition, the Kirin battery adopts an inverted cell design with the explosion-proof valve facing downward. When the thermal runaway of the cell occurs, high-temperature airflow will be sprayed to the bottom of the car to further protect the safety of drivers and passengers. Kirin battery is an important way for CATL to further improve battery performance through structural innovation under the existing prismatic battery technology route.

3. Conclusion

With the current rapid development of new energy vehicles and the final full-scale popularization in the future, it will be inseparable from the continuous innovation of battery materials and the continuous improvement of integration technology. Battery technology will always focus on several aspects such as cost, battery life, safety, and fast charging. Only when these core indicators have made a qualitative leap can it be possible to usher in an era that truly belongs to new energy vehicles.

Related articles: Tesla 4680 battery vs CATL CTP battery, m3p battery, 4680 battery vs 18650