Your Vision, Our Power Core.

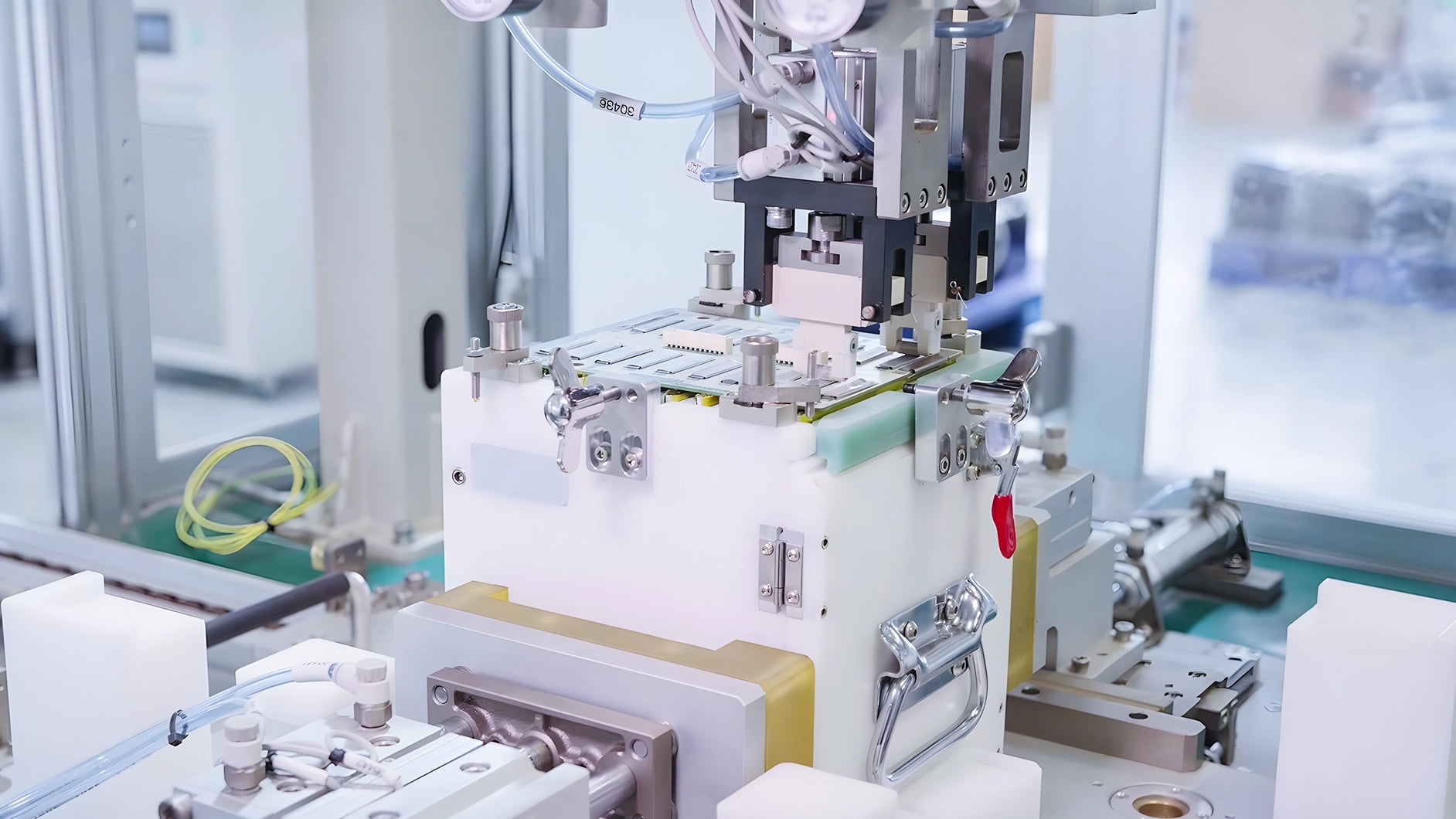

We don't sell off-the-shelf batteries; we engineer custom power solutions. From unique form factors and housing to smart BMS integration, our team works with you to design a battery pack that seamlessly fits your product, maximizing performance and user experience.

Explore Our Case Studies

Two Paths to Peak Performance: LFP & Semi-Solid.

Choose the chemistry that fits your mission. Opt for our LiFePO4 (LFP) series for unmatched safety, ultra-long cycle life, and superior thermal stability. Or, select our cutting-edge Semi-Solid State series for higher energy density, lighter weight, and faster charging capabilities. We guide you to the right choice.

Discuss Your Project

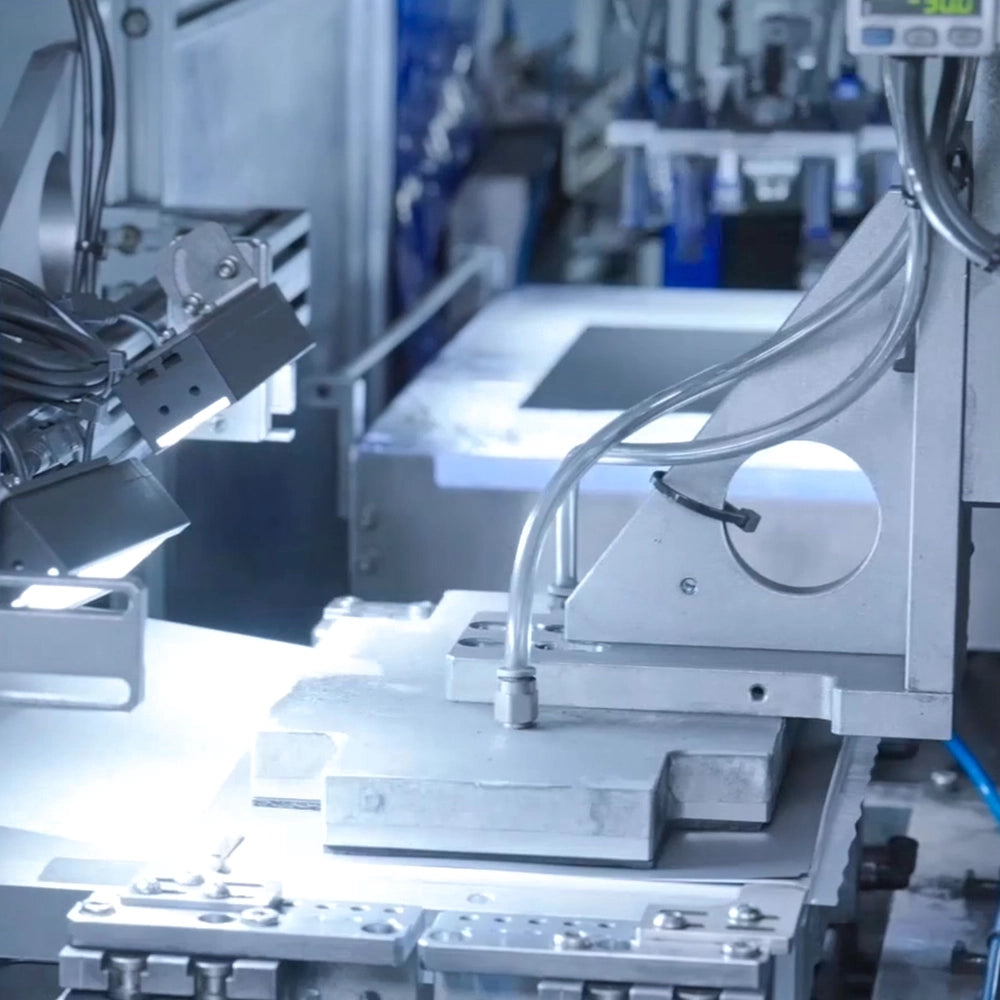

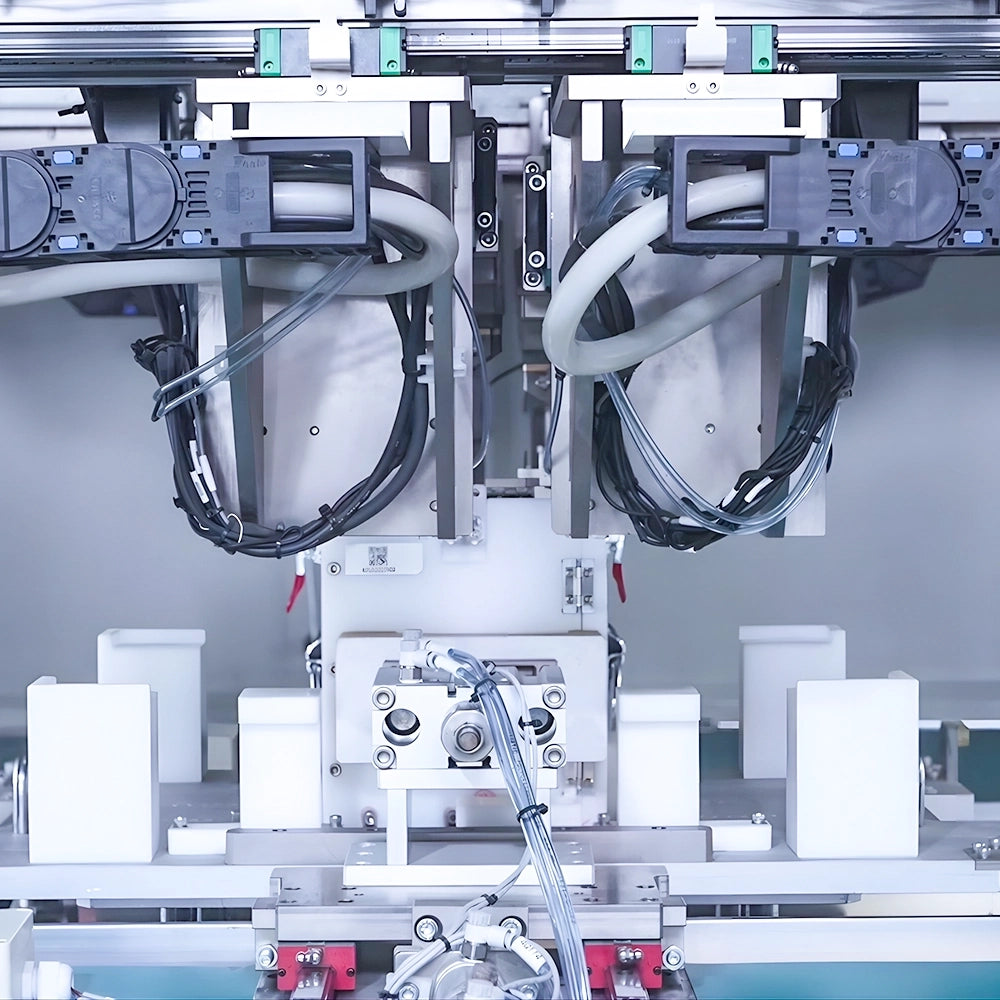

Industrial-Grade Reliability. Certified Performance.

Every battery solution we deliver starts with Tier-1 certified cells and is assembled in our state-of-the-art facility. Each pack undergoes rigorous testing for vibration, shock, water ingress (IP67), and extreme temperatures to guarantee unwavering reliability in the field.

Tour Our Facility

Your Power Partner, From Prototype to Scale.

Our partnership extends beyond delivery. We offer rapid prototyping to accelerate your development, scalable manufacturing to support your growth, and dedicated post-sale technical support to ensure your success. We invest in your journey.

Start Your Project Today

Your Vision, Our Power Core.

Two Paths to Peak Performance.

Industrial-Grade Reliability. Certified Performance.

Your Power Partner, From Prototype to Scale.