Bringing Clarity to Chaos.

Facing Problems by Yourself

Testing different batteries by yourself, wasting time, and risking mismatches.

Tackling Them with Top Advisors

Proven solutions mapped by specialists, saving hours and avoiding costly mistakes.

Range Anxiety / Charging Pressure

Traditional lead-acid batteries provide only 50–70 km range with a cycle life of 400–500 cycles, creating frequent charging needs.

SLA to Lithium Upgrade

Lithium batteries extend range up to 200 km with up to 4,000 cycles, reducing charging frequency by 60–70% and easing operational pressure.

Insufficient Peak-Time Capacity

Large buses on fixed schedules can’t handle daily rush-hour surges. Passengers face ~15-minute waits and crowding at stops, leading to frustration and management pressure.

Flexible Three-Wheel Deployment

Battery-swap three-wheelers supplement routes instantly, cutting waits to under 3 minutes and boosting peak-hour capacity by 20–30% for smoother daily operations.

High Maintenance Costs

Lead-acid batteries age quickly, causing voltage drops and acid leaks that stress cables, connectors, controllers, and chassis, leading to 2 major overhauls per bus per year (~$3,000 reported by a client).

Reduced Maintenance Costs

Lithium battery replacement increases pack life from 400–500 cycles to 4000 cycles, stabilizes voltage, and protects components, cutting annual maintenance by 30–50% with fewer breakdowns.

Limited Route Flexibility

Due to their large size, these vehicles struggle to navigate narrow roads, resulting in coverage of less than 50% of the narrow routes

Broader Coverage

Introducing flexible three-wheelers expands service coverage, raising accessibility on branch and smaller routes to over 80%.

Unstable Passenger Flow

Holiday surges and special events overwhelm fixed schedules, causing delays and frustrated visitors. Buses operate on rigid timetables, leading to 70–80% punctuality during peak days.

Integrated Scheduling System

Mainline buses handle regular routes, while flexible tricycle feeders quickly respond to sudden demand spikes. Punctuality climbs to 95%, ensuring smooth operations even on the busiest days.

Integrated EV Upgrade & Battery Swap Solution - Scenic Spots & Campus Fleets

How We Strengthen Your Fleets

Upgrade your fleet with lithium conversions and smart battery swap systems to reduce maintenance, lower energy costs, and improve operational efficiency. Ensure smooth rides, flexible scheduling, and scalable solutions for every peak season or special event, all while saving money and minimizing hassle.

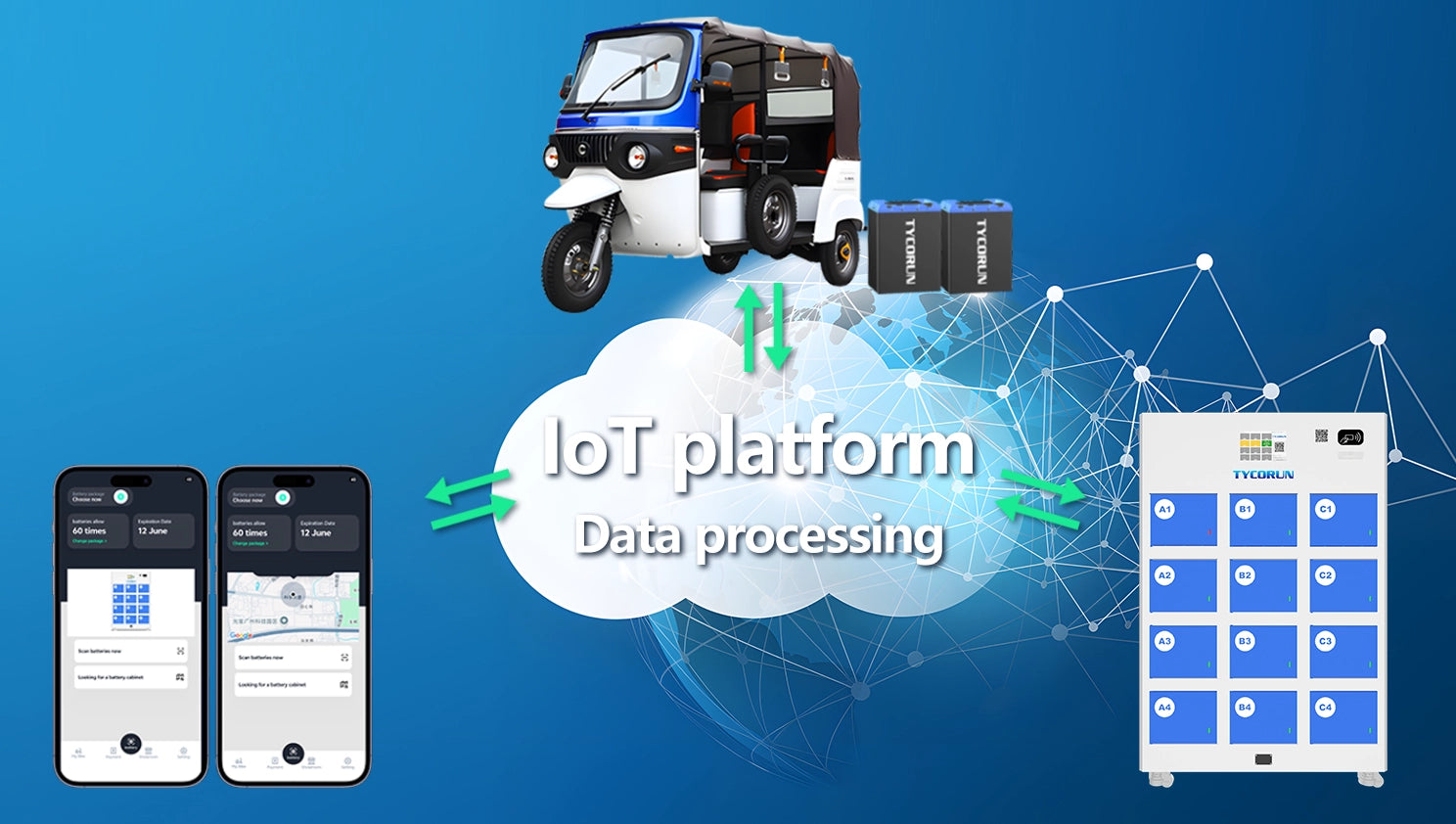

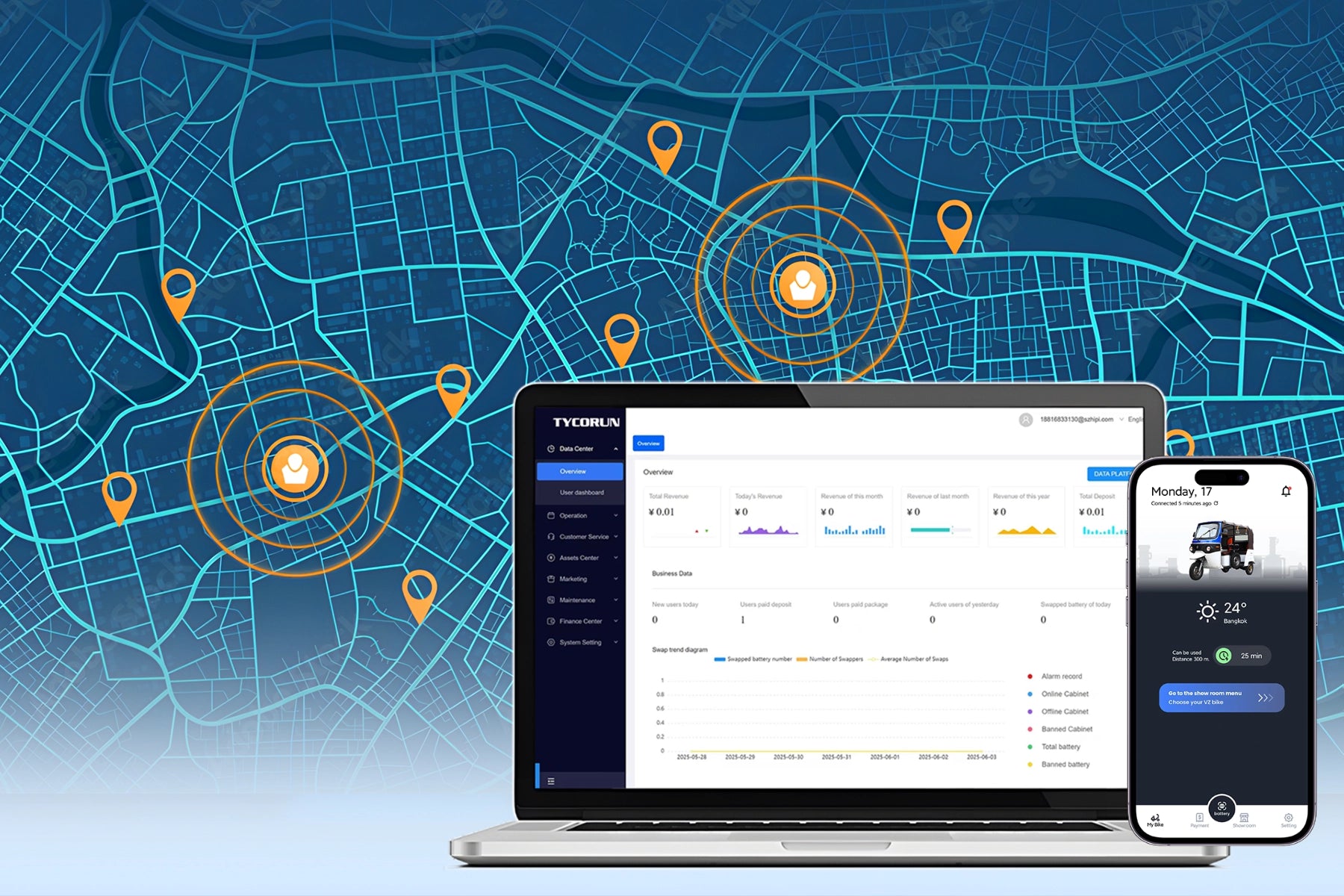

Smart Feeder Fleet Management

Our software streamlines three-wheeler battery swaps with a unified mobile app and backend dashboard. This targeted solution enhances the efficiency of flexible feeder vehicles, complementing lithium-upgraded buses for smoother overall operations—without implying full fleet control.

Operations & Maintenance Support

We ensure your equipment runs smoothly with end-to-end technical services—covering installation, training, and rapid support. Our role is to keep the hardware and software we provide reliable, so your team can focus on daily operations.

Choose Electric, Not Fuel

Don’t be tempted by the short-term savings of fuel vehicles. Electric three-wheelers deliver real, measurable benefits: lower operating costs, faster service, reduced maintenance, and cleaner operations.

Cost Savings

Electricity is far cheaper than fuel, and maintenance is minimal. Fuel vehicles may seem cheaper upfront, but hidden costs add up quickly.

- Energy costs down 80%+

- Annual profits up 30%

- Maintenance costs down 30%

Efficiency Gains

Swappable batteries keep your fleet running continuously—fuel vehicles cannot match this speed or reliability.

- Swap time cut to 12 sec

- Peak-hour trips up 25%+

- Wait times under 2 min

Customer Satisfaction

Reduce CO₂ emissions while enhancing your campus or scenic spot’s green credentials.

- Wait time down 60%

- Ride experience up 40%

- On-time rate at 95%