Main content:

Since the outbreak of the global oil crisis in the 1970s, solar photovoltaic power generation technology has attracted great attention. The PV industry is growing rapidly around the world, and after years of research and technology development, the price of solar PV modules has dropped significantly.

In addition, solar energy conversion efficiency has also improved, making the commercial development and application of solar photovoltaic power generation a reality.

1. Classification of photovoltaic inverters

There are four main categories of PV inverters: centralized, serial, distributed, and micro. Among them, centralized inverters and string inverters are the mainstream products of photovoltaic inverters in China, accounting for 45% and 42% respectively.

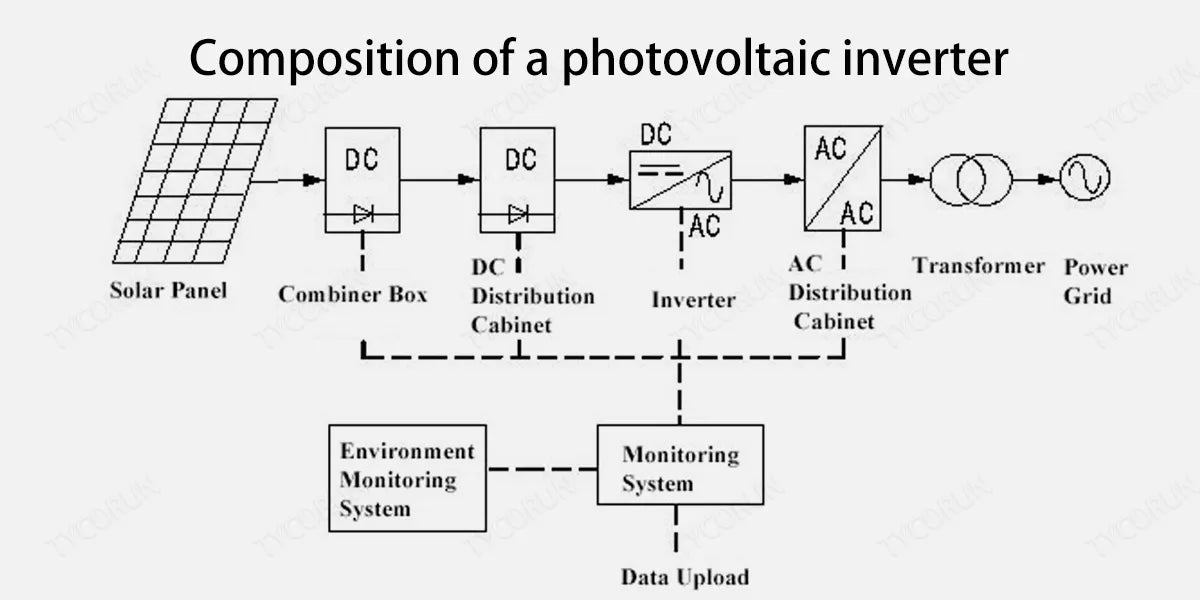

2. Composition of a photovoltaic inverter

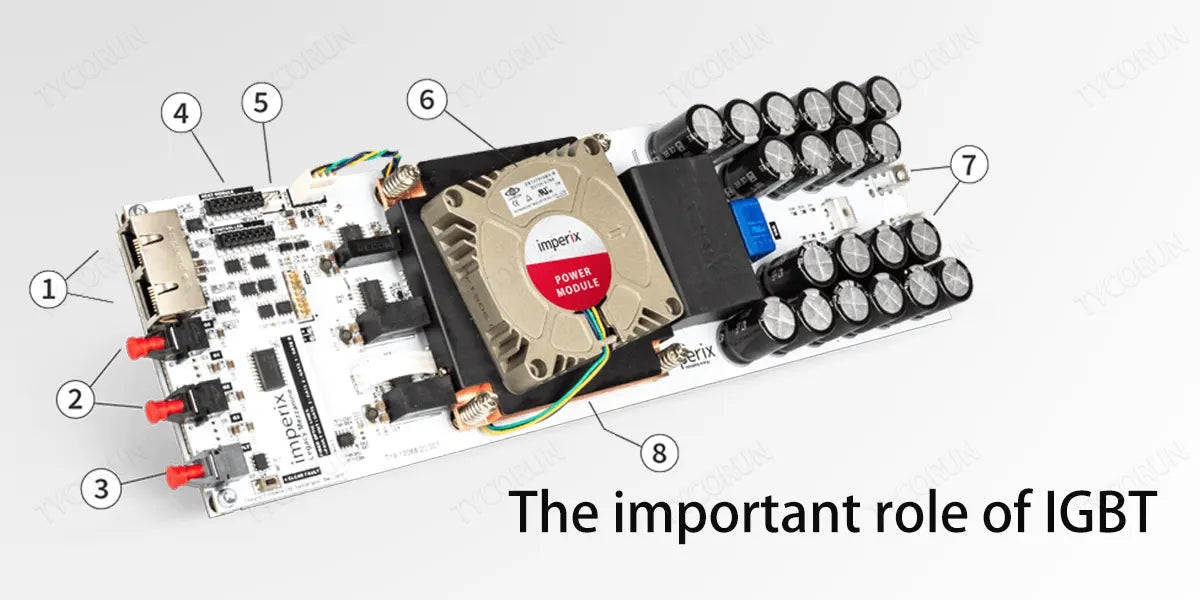

From the perspective of the cost composition of photovoltaic inverters, the direct material cost accounts for a very high proportion, more than 80%, which can be roughly divided into four parts: power semiconductors (mainly IGBT), mechanical parts (plastic parts, die-casting parts, radiators, sheet metal parts, etc.), auxiliary materials (insulating materials, packaging materials, etc.), and other electronic components (capacitors, inductors, integrated circuits, etc.).

Among them, semiconductor devices dominated by IGBTs account for about 11.8% of the inverter cost. By the end of 2021, the installed capacity of grid-connected photovoltaic power generation reached 306 million kilowatts, exceeding 300 million kilowatts, ranking first in the world for seven consecutive years.

The industry has developed rapidly, and the photovoltaic industry has officially entered the era of grid parity. Among them, the newly installed distributed pv system has been growing, and the level of photovoltaic consumption in many regions has increased significantly.

3. The important role of IGBT

The core utilization of IGBT in power inverter 3000w is reflected in four aspects: drive protection, overcurrent/short circuit protection, overtemperature protection, and mechanical fault protection. As a power device, IGBT plays the role of power conversion and energy transmission in the inverter and is the heart of the inverter.

At the same time, IGBT is one of the most unreliable components in the inverter, which is very sensitive to the temperature and current of the device, and will blow up and be irreparable if it exceeds the standard. Therefore, IGBT is the key protection object of the inverter.

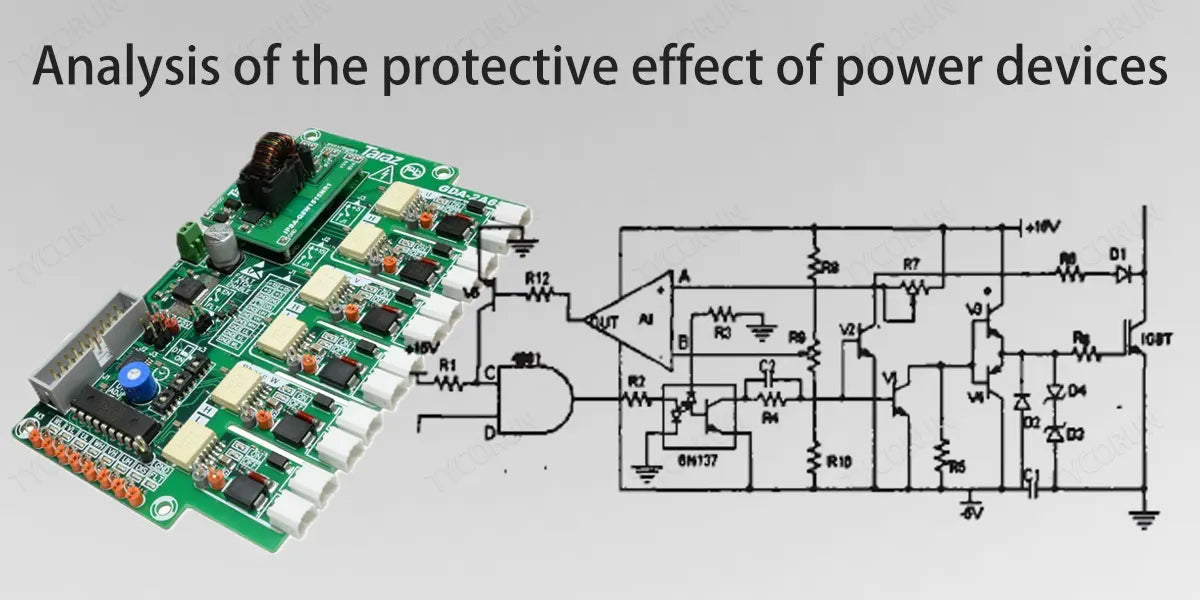

4. Analysis of the protective effect of power devices

- Drive protection

IGBT itself is a current switching device. How long the switch is controlled by the inverter CPU, but the DSP output is a PWM signal. The speed is fast, but the power is not enough. The main role of the driver is to amplify the PWM signal.

IGBT controls a large high frequency and high current, will produce electromagnetic interference signals, and the driver is very close to the IGBT, so the drive circuit should have an isolation function, and the current drive isolation scheme has several kinds of optocouplers, optical fibers, pulse transformers, magnetic couplers, etc.

- Overcurrent and short-circuit protection

When designing IGBTs, there is usually more than 10% of the current space. However, when the 2000w inverter is working, it is overcurrent due to short circuit components and loads, and load side faults.

There is a particularly large inductive load on the roadside, and there is a large harmonic current when starting and stopping. At this time, the output current of the inverter will rise sharply, and the operating current of the inverter IGBT will also rise sharply.

There are two types of short circuits: a straight through occurs in the bridge arm of the converter, which is called a short circuit type. The converter's short-circuit point occurs on the roadside, and the equivalent short-circuit impedance is large, which is called a type II short-circuit.

The second type of short circuit can generally be regarded as a serious overcurrent of the inverter. At the moment of short circuit, if no relevant measures are taken, the IGBT will quickly enter desaturation, and transient power consumption will exceed the limit value and be damaged. This is because the overcurrent is only a few microseconds.

Therefore, when a short circuit occurs, the IGBT should be turned off as soon as possible, and speed of the shutdown should be smooth to ensure that the current change rate is within a certain range, so as to avoid the voltage stress exceeding the limit and damage caused by the shutdown too fast, and add rapid response measures in the scheme to make the IGBT driver act as soon as possible.

- Over-temperature protection

When the ambient temperature of the inverter is too high, the heat dissipation of the inverter is poor, and the continuous overheating will lead to the damage of the IGBT.

If the device continues to short-circuit, the power dissipation generated by the high current will cause a temperature rise, and if the chip temperature exceeds the intrinsic temperature of the silicon (about 250°C), the device will lose its blocking ability, and the gate control will not be able to protect, resulting in failure.

In the design, it is mainly considered from two aspects: first, strengthen and improve the heat dissipation conditions of IGBT tubes, including air duct design, heat sink design and production, and strengthen refrigeration.

Second, it is very accurate to design an overheat detection protection circuit and use the built-in thermistor on the IGBT module to measure the heat dissipation temperature. When the temperature exceeds the set value, turn off the IGBT to stop working.

- Mechanical fail-safe protection

In order to facilitate heat dissipation, IGBTs are connected by screws and installed on the heat sink. The connection strength of this screw should be just right, neither too much force nor too light. If the force is too great, it will damage the IGBT. If the force is too light, during transportation and installation, vibration will cause poor contact, increased thermal resistance, and excessive temperature damage to the device.

When installing IGBTs, special screwdrivers are used, and according to different models, the corresponding torque is used to ensure that the connection is firm and will not be damaged.

5. Conclusion

The photovoltaic inverter is the core equipment of the photovoltaic power generation system, and its main function is to convert the direct current generated by the photovoltaic power generation system into alternating current.

And it is able to track the maximum output power of the photovoltaic module array, and use its energy for electrical equipment applications or feed into the power grid with the minimum conversion loss and the best power quality.

Related articles: photovoltaic module, top 10 solar inverters, off grid solar batteries