Since Tesla announced that its 4680 battery adopting a tabless structure, "full-tab large cylindrical batteries" have become the focus of the industry attention. Full-tab batteries are highly praised for their advantages such as high safety and super fast charging, which have also promoted the rapid development of the battery tab industry.

This article will introduce you to the global market development status and trends of battery tabs, as well as listing some representative companies.

Main content:

1. Global market size of battery tabs

Battery tabs are metal conductors leading from the positive and negative poles of the soft core. The positive electrode of lithium batteries is made of aluminum, while the negative electrode material is nickel and nickel-plated copper, both of which are combined with a modified PP binder and metal strips.

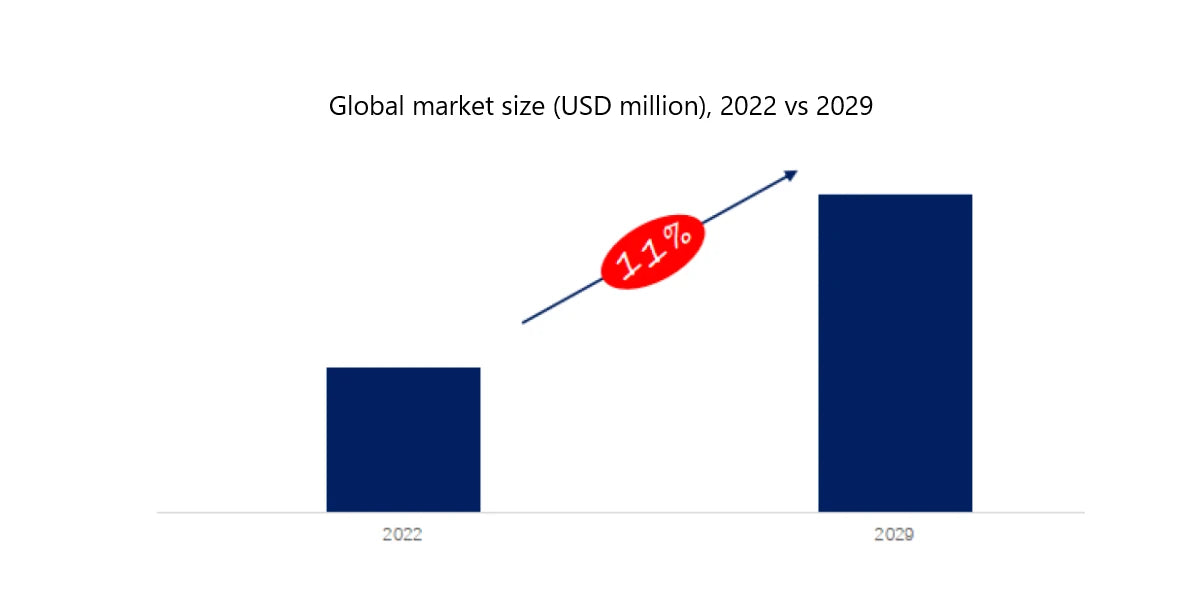

According to research reports, the global battery tab market size will reach US$1,427 million in 2029, with a compound annual growth rate of 11% in the next few years.

2. Driving factors for the development of battery tabs

- Advantages of full-tab batteries

Full-tab batteries are gaining popularity because they combine the pain points of new energy batteries such as high safety, high energy, and super fast charging. Due to the existence of resistance, the battery temperature can easily rise during the charging and discharging process, especially the high-current charging and discharging process.

The high safety of the large cylinder makes it the best carrier for both high energy and super fast charging. It can solve the contradiction between increasing the size of the battery cell and reducing heat generation, so that there are no concentrated heating spots inside the battery and better safety performance.

- Promotion of electric vehicle market

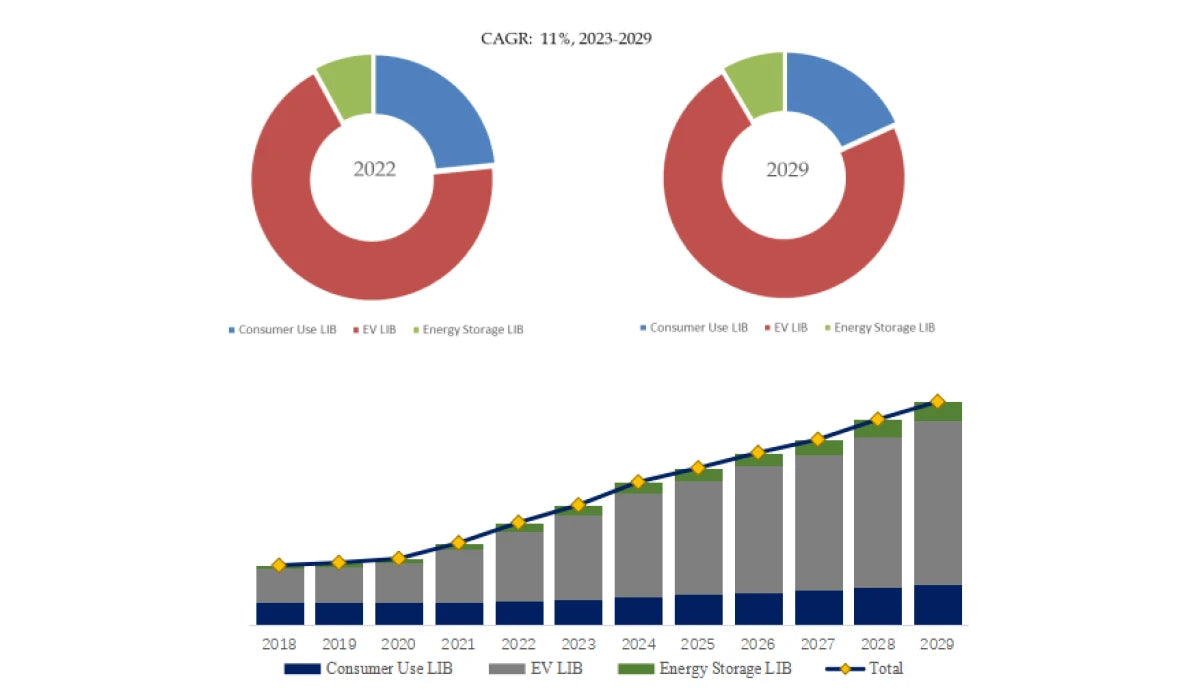

Electric vehicles are currently experiencing an upward trend in the long-term prosperity of the industry. The leading industry application, power soft-pack batteries, including golf cart battery, have benefited greatly and have broad market prospects. The accelerated explosion of the global electric vehicle market has driven a corresponding rapid growth in demand for power batteries.

According to conservative predictions by industry organizations, global electric vehicle sales will exceed 20 million units by 2025, and the corresponding demand for power wheels battery will exceed 1,600GWh. Among them, full-tab large cylindrical batteries will move from research and development to actual mass production.

The tabs are metal conductors drawn from the positive and negative poles of the battery core. They are connected to the battery case or external module structural components. Current must flow through the tabs to connect to the outside of the battery.

Many battery companies have invested significant resources in developing cylindrical cells with innovative lug designs and larger diameters, and battery companies such as Panasonic, LG Chem, Samsung SDI and BAK Battery have confirmed that they are developing full-tab batteries.

In terms of OEMs, Tesla's large cylindrical batteries have led to the entry of many OEMs. OEMs such as NIO, JAC, Porsche, and Voyah will also equip their mid-to-high-end models with 4680 large cylindrical batteries.

- Energy crisis promotes industry progress

In recent years, as oil resources continue to shrink, various countries have successively issued timetables for banning the sale of fuel vehicles. New energy vehicles have become the main trend in the future development of the global automobile market. As the core component of new energy vehicles, the market demand for power lithium batteries is bound to grow rapidly.

3. Factors hindering the development of battery tabs

- Raw material price fluctuations

The main raw materials of battery tabs are aluminum, copper, etc. In recent years, the prices of steel and non-ferrous metals have fluctuated, causing the purchase price of the main raw materials of battery tabs to fluctuate accordingly.

- Technical threshold

To remain competitive, companies need to continually invest in R&D and manufacturing. As standards for manufacturing processes for new products improve, business expenses will rise. The innovation of the full-tab process brings many process difficulties in the battery production process, such as the slitting process, liquid injection process, flattening process, laser welding process, etc., which directly affects the yield rate of 4680 batteries.

At the beginning of 2022, according to information from Tesla motors clubs, the average yield rate of Tesla's Fremont factory reached 92% on January 22, 2022, which was relatively high, but compared with 2021, it is significantly improved. However, there is still a certain gap compared to the 95%+ yield rate of 21700 cylindrical batteries.

This requires companies to have mature production processes and market experience to achieve both performance and cost, and better collaboration among battery companies, material companies, and equipment companies, in order to speed up the development efficiency of full-tab batteries and improve battery levels to ensure the quality of full-tab batteries to guarantee an advantage in the competition of battery tabs.

4. Industry development trends

- China’s share expands: As major companies continue to invest in production capacity, China’s share of global output continues to expand, and exports surge year by year.

- Expansion of application fields: In addition to the steady growth trend of traditional consumer electronics such as smartphones and computers, in recent years, thin and small emerging consumer electronics products such as wearable bracelets and TWS headsets have also become new growth points.

5. Market share of different kinds of battery tabs

There are three types of battery tabs: aluminum, nickel, and nickel-copper. The positive electrodes are usually aluminum tab, and the negative electrodes are nickel tab and copper nickel-plated tab.

Nickel tabs are mainly used for consumer lithium batteries, including 18650 battery; copper-plated nickel tabs are mainly used for power lithium batteries or high rate batteries like 12v 100ah lithium ion batteries or 12v 200ah deep cycle battery. In terms of product type, aluminum tabs account for a relatively large share, accounting for approximately 47%.

6. Major companies of battery tabs

Globally, major battery tab companies include Sumitomo Electric, Shanghai Tokuen, NEPES, Clavis, Zhejiang Tony Tech, Jiulan Technology, Soulbrain, POLE, ELCOM CO, Dongguan Huachuang Power, etc. Among them, the top five companies account for approximately 55% of the total market share. At present, the global core companies are mainly located in China, South Korea and Japan.

The downstream battery tabs are mainly used for soft pack batteries. The major global soft pack battery companies include LG Chem, SKI and Farasis Energy. In terms of product applications, lithium batteries for electric vehicles are the largest application, accounting for 72% of the market share.

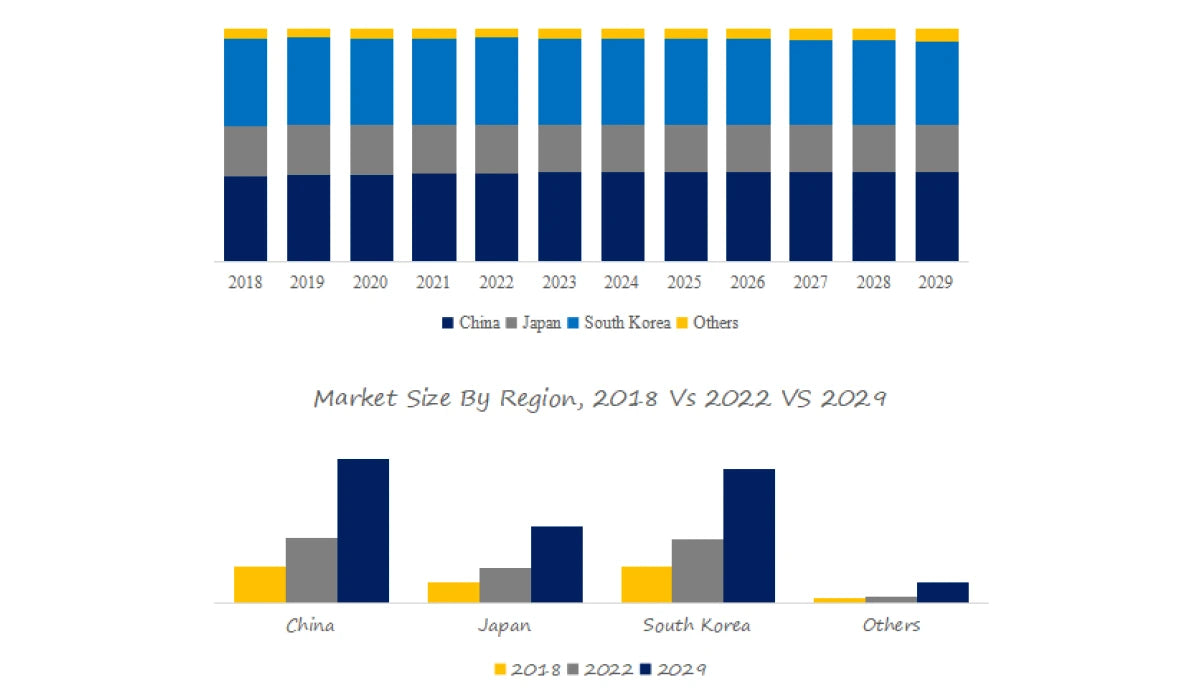

7. Market size of battery tabs by region

As far as the production side is concerned, the current production areas of battery tabs are mainly distributed in China, South Korea and Japan, and these three regions dominate the market. Among them, China’s market output value share is close to 40%, followed by South Korea, which charges 36%.

Related posts: Battery tab, How does a car battery work, Lithium ion battery pack