main content:

With the increasing global demand for environmental protection and energy efficiency, hybrid vehicles have become an important development direction for the future of transportation. Hybrid power systems achieve higher energy efficiency and lower emissions by combining the advantages of traditional internal combustion engines and electric motors.

This article will introduce in detail the working principle, advantages and disadvantages of two common Hybrid systems, Series Hybrid System and Parallel Hybrid System, as well as their applicability in practical applications. Help you gain insight into these advanced powertrain technologies and better understand what a hybrid vehicle is.

1. Series Hybrid Vehicle

As shown in Figure 1, a series hybrid system consists of an engine, a generator, a motor controller, an electric motor and a power battery. Its working principle is that the engine drives the generator to generate electricity, and the generated electric energy is supplied to the motor through the motor controller, and then the motor is converted into kinetic energy to drive the vehicle. The power battery adjusts the electric energy generated by the generator and the electric energy required by the electric motor, thereby ensuring the power demand of the vehicle under various driving conditions.

This type of hybrid is driven entirely by electric motors. The vehicle is powered by batteries at low speeds and recovers energy during regenerative braking. When the battery is low, the gasoline engine starts, but it does not drive the wheels directly, but converts the gasoline energy into electricity through the generator, which continues to charge the battery to keep the motor running.

Although there is some efficiency loss in energy conversion in this way, it provides smooth power transmission.

Figure 1 - Series Hybrid System

The series hybrid system is mainly used in urban buses, and the fuel saving rate can reach about 20%. Among them, the series hybrid system has three basic working modes.

(1) The first basic working mode mainly uses the battery to drive the vehicle, and the internal combustion engine starts only when the battery SOC is reduced to a minimum value. Since the internal combustion engine does not directly participate in driving the vehicle, it can work in the highest efficiency region and output constant power. When the SOC rises back to the maximum limit, the internal combustion engine stops. This mode is also known as "thermostat-style control".

(2) The second basic working mode is the "load following" control mode. In this mode, the SOC of the battery is kept within the specified range, the internal combustion engine drives the generator to work and supplies as close as possible the electric energy required for the vehicle to travel, and the battery only plays the role of regulating the load. In this mode, the charge and discharge of the battery is smaller, and the energy loss is also minimized. The disadvantage of this mode is that the internal combustion engine cannot work at the optimum speed and load, so its emissions may be worse and its efficiency may be reduced.

(3) The third basic working mode is a compromise of the above two modes (or control strategies). When the SC of the battery is high, the pure electric mode is mainly used. When the SOC of the battery is reduced to a set range, the internal combustion engine drives the generator to work. Considering the emission and efficiency of the internal combustion engine, it is necessary to strictly limit its output power within a certain range of variation. If the total energy demand for the vehicle's trip can be predicted, once enough energy is stored in the battery, the vehicle can switch to pure electric mode for the remainder of the trip, draining the battery at the end of the trip. This mode or strategy is also known as the optimal series hybrid drive mode.

The series hybrid electric vehicle has the following advantages.

①The working state of the engine is not affected by the driving conditions of the vehicle, and can always run stably in the best efficiency area, so it has good economy and low emission performance;

② There is no mechanical connection between the engine and the motor, and the structural arrangement of the vehicle has a greater degree of freedom. Various drive system components can be placed in the most suitable vehicle position, such as on a low-floor bus, the engine generator can be assembled at the rear of the vehicle or other parts and driven by electric wheels, thereby reducing the floor height;

③Due to the large power of the motor, the potential of braking energy recovery is large, thereby improving the utilization efficiency of energy.

The disadvantages of the series hybrid system are as follows.

①The energy generated by the engine reaches the driving wheel after two energy conversions, which causes a lot of energy loss and low efficiency;

②The use of generator increases the quality and cost of the vehicle;

③ Since the electric motor is the only power source for driving the vehicle, its size is large in order to meet the performance requirements of the vehicle such as acceleration and climbing.

According to the above characteristics, series hybrid electric vehicles are more suitable for low-speed running conditions in the city, but not suitable for highway driving conditions.

2. Parallel Hybrid Vehicle

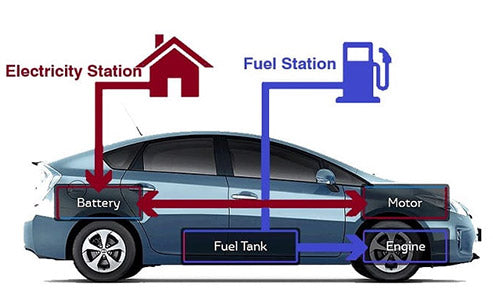

As shown in Figure 2, the parallel hybrid system consists of an engine, a transmission, a motor, a motor controller and a power battery, where the motor can not only provide power output for the vehicle, but also act as a generator. A vehicle using a parallel hybrid system has two independent drive systems, namely an engine drive system and a motor drive system. The driving force of the vehicle is supplied by the engine and the motor at the same time or separately. The two sets of power systems can work in harmony at the same time or work independently to drive the car. When the two power systems work at the same time, the power coupling is realized mechanically, and the power flow is parallel, so it is called a parallel hybrid power system.

Figure 2 - Parallel Hybrid System

The parallel hybrid system mainly has the following two basic working modes.

① The internal combustion engine-assisted hybrid mode mainly uses the battery-motor system to drive the vehicle, and the internal combustion engine is only used when driving at a high cruising speed, climbing hills and accelerating rapidly;

②The motor-assisted hybrid mode mainly uses the internal combustion engine to drive the vehicle, and the motor is only used in two states;

First, it is used in conditions that require peak power such as instantaneous acceleration or climbing, which can make the internal combustion engine work in the highest efficiency range to reduce emissions and reduce fuel consumption; second, when the vehicle decelerates and brakes, the motor is used to recover the kinetic energy of the vehicle (regenerative braking) to charge the battery.

This type of hybrid uses a gasoline engine and an electric motor, and can use either power source alone, or both. Electric motors typically operate at low speeds because of their ability to deliver high torque and greater efficiency, especially when battery energy is limited.

The advantages of a parallel hybrid system are as follows:

①The power of the engine can be directly used to drive the vehicle, there is no energy conversion, and the energy loss is small;

②The motor can not only drive the vehicle, but also can be used as a generator, and can use less power to reduce costs.

The disadvantages of a parallel hybrid system are as follows:

①Due to the traditional mechanical connection between the engine and the driving wheels, the working point of the engine (the balance point of fuel consumption and power performance) cannot always be in the best area, and the efficiency of the engine cannot be fully utilized. It needs to be equipped with a transmission and is suitable for an automatic transmission;

② The degree of mixing is low, which is not conducive to the transition to plug-in hybrid.

Conclusion:

It is necessary to know what a hybrid car is as well as the unique advantages and application scenarios of different hybrid power systems. Hybrid power system and parallel hybrid power system have their unique advantages and application scenarios.

With its stable engine efficiency and superior energy recovery capability, series hybrid systems are particularly suitable for low-speed urban driving applications, which can effectively reduce energy consumption and emissions. In contrast, the parallel hybrid system uses the internal combustion engine and the electric motor to work together to achieve optimal power output in a variety of driving conditions, suitable for high-speed driving and a wider range of applications.