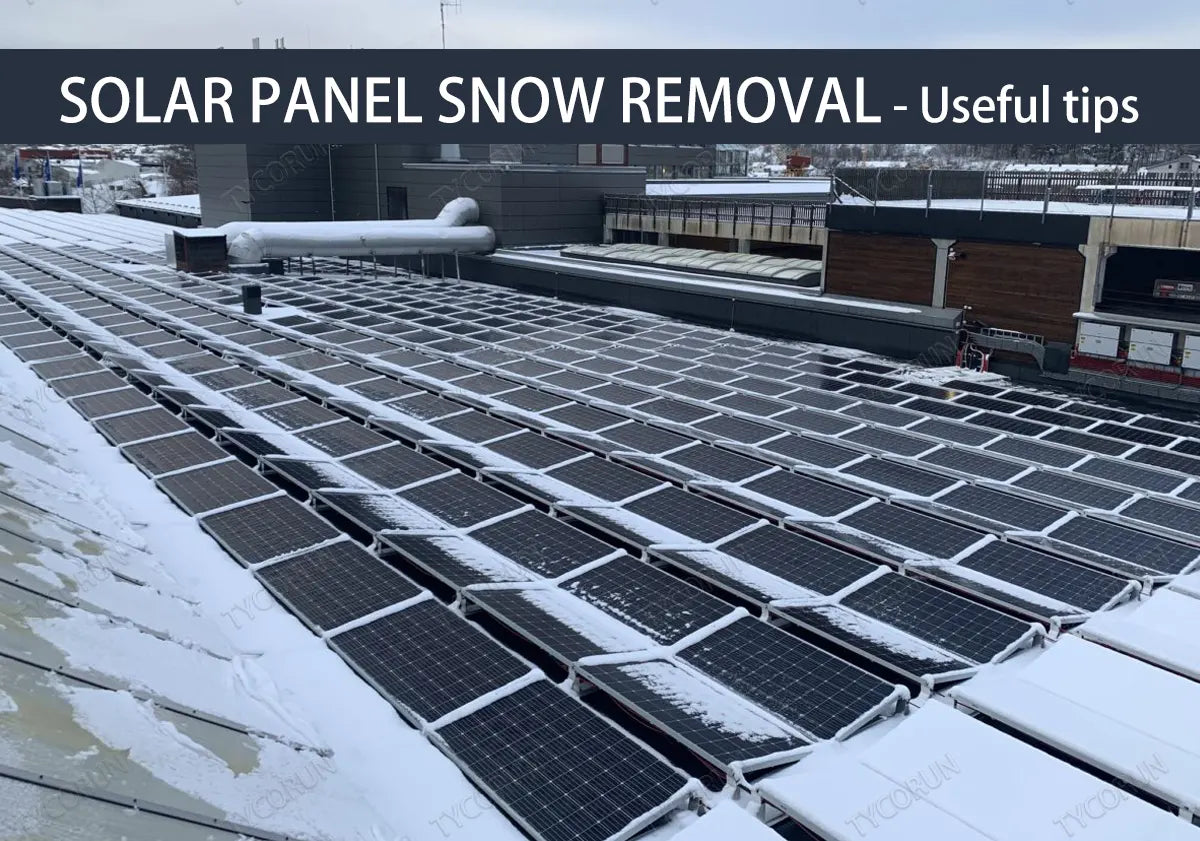

Rain and snow fall in many areas in winter, and in a persistent low temperature environment, if the snow cannot be cleared in time, it will easily freeze. This will not only seriously affect the power generation efficiency, but also very likely to cause unpredictable damage to the components.

Through the economical, reasonable and simple method, no matter photovoltaic power stations or home solar power system users, can quickly melt and remove snow in winter, which will help increase the power generation of photovoltaic power stations and reduce operation and maintenance workload and costs.

So how to use economical and reasonable methods to quickly melt the snow and proceed solar panel snow removal? What are the common snow removal methods? This article will introduce it to you.

Main content:

1. The impact of snow on solar panels

If the snow stays on the solar panel for a long time, it will form a hot spot effect. When a solar panel was affected by hot spot effect and cannot generate electricity, it will consume the energy generated by other solar panels that are illuminated, and the shaded solar panel will generate heat.

At this time, the bypass diode will be turned on, and the current generated by other panels will flow out from the diode, allowing the solar power generation system to continue generating electricity and power the electrical appliances through 2000w inverter or 3000w inverter, and the power generation circuit will not be blocked due to problems with one panel.

As a result, the occlusion of a small number of cells will cause most of the off grid solar batteries or the entire panel to be "bypassed". So solar panel snow removal is crucial for the normal use of solar panels.

2. Notes on solar panel snow removal

- Cracks in solar panels are generally caused by human, so do not shovel snow with metal objects such as shovels to avoid damaging the surface of the photovoltaic modules.

- When the snow is very thick, you can use a soft cloth to sweep away the snow on the surface, and then clean the surface.

- Do not use hot water to wash away the snow. Uneven heat and cold will damage the photovoltaic modules.

- Don't wait until the snow has accumulated for a long time before solar panel snow removal. If the temperature is too low and ice forms, it will also damage the power generation of the components.

- In addition, during the rain and snow season, it is also necessary to check the fixation of the bracket in time and check the stability of the bracket.

3. Methods of solar panel snow removal

① Manual snow removal

If there is heavy snow accumulated on the components after snow, solar panel snow removal is required. It is very important to use soft objects to push the snow off and be careful not to scratch the glass. Otherwise, the components will be cracked or damaged, which will affect the life of the components. It is generally recommended not to wait until the snow till it’s too thick before cleaning, to prevent the components from freezing.

Under normal circumstances, photovoltaic power stations can only arrange specialized personnel to use soft objects to push the snow down. When faced with square arrays with complex terrain or components high above the ground, it is almost impossible to start the process, which is inefficient and consumes a lot of human and financial resources. At present, most photovoltaic power plants still use the most traditional method of manual solar panel snow removal.

- Advantages: This method of solar panel snow removal is simple and the working tools are simple.

- Disadvantages: Low work efficiency and high cost. If unscientific methods and tools are used, it is easy to scratch the surface glass of photovoltaic modules.

② Adjust the tilt angle

Installing solar panels at a wide solar panel angle can reduce the speed at which snow accumulates, eliminating the need to clear the snow from time to time. When you are hesitating whether to choose 30° or 40°, 40° will be a better solution.

If your solar panel is placed flat, the snow or pollutants that will definitely stay on the photovoltaic panel for a long time and will not slip off. The solar panels can be tilted 40° in winter and 20° from spring to autumn to increase power generation.

③ Automatic snow and dust removal components

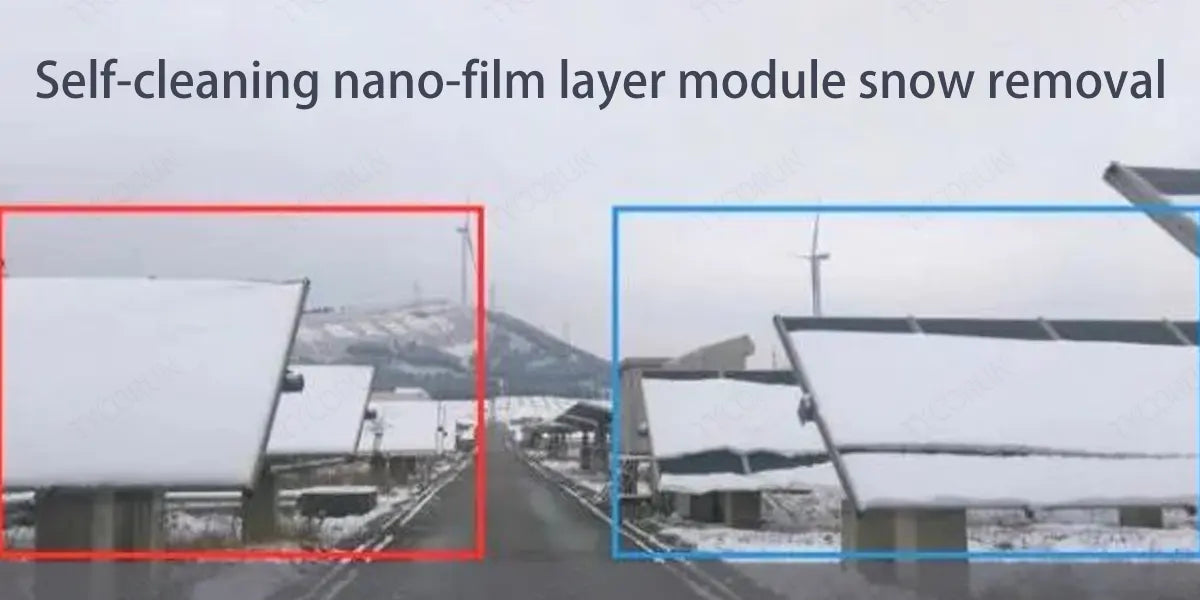

Faced with the problem of snow accumulation, the use of self-cleaning nano-membrane will achieve a good snow melting effect because the self-cleaning nano-membrane has super hydrophilicity. In normal weather, water droplets will spread evenly after landing on the glass surface, reaching the maximum contact area with the glass surface. It is easier to take away large areas of pollutants, or dust and sand on the surface of photovoltaic modules can be removed with less water or rain.

When it snows, the self-cleaning nanofilm layer can connect the tiny water droplets that gradually melt under the snow to form a water film. Under the action of gravity, the snow slides more easily on the water film, thus achieving faster melt and slide off.

At present, the cost of automatic snow and dust removal photovoltaic modules with SSG's self-cleaning nanofilm layer is slightly more expensive. In some severely cold areas, due to the low ambient temperature, it is difficult for the self-cleaning nanofilm layer to connect the tiny water droplets that gradually melt in the lower layer of snow to form a water film, so the reliability of solar panel snow removal needs to be further verified.

Left: Snow accumulates on the surface of conventional components, with no signs of slipping.

Right: There is snow on the surface of the SSG component, and large chunks of the snow have broken off and begun to slide.

④ Snow removal by sweeping robot

The photovoltaic component intelligent cleaning robot usually uses an intelligent control system to adopt waterless dry cleaning, automatic scheduled cleaning, cloud background control, and unattended working mode. It has its own photovoltaic components, which can self-generates energy and stores electricity for solar panel snow removal, and does not require an external power supply, thus reducing the loss of power generation caused by snow and dust.

⑤ Automatic snow removal with tracking bracket

When it snows, adjusting the solar panel assembly to the maximum inclination angle can effectively reduce the snow accumulation on the surface of the assembly. When there is no snow, return the solar panel assembly to its normal mode. On snowy days, photovoltaic power station operation and maintenance personnel can remotely control the inclination of the photovoltaic modules to a protective angle, which is conducive to snow falling and preventing snow from forming.

This solution of solar panel snow removal is only suitable for tracking bracket systems such as flat single-axis, oblique single-axis, and dual-axis tracking. And it is difficult for fixed brackets to achieve the same effect. Fixed and adjustable brackets need to adjust the angle of the photovoltaic array to the maximum possible before snow falls. In this way it can reduce the impact of snow on photovoltaic modules.

![]()

⑥ Snow removal with double-glass double-sided modules

After a snowy day, the ground surface is covered with snow, and the surface's ability to reflect sunlight is enhanced, that is, the reflectivity of the back side of the module increases, which enhances the power generation capacity of the back side of the double-glass bifacial photovoltaic module.

The back side of the double-glass double-sided photovoltaic module can achieve photoelectric conversion through diffuse reflection of snow on the ground to continue generating electricity. The heat released during the conversion process will quickly melt the snow on the front of the module close to the module, forming a water layer.

The friction between the snow and the components is reduced, and the snow on the surface of the components can slide off under the action of gravity, reducing the area and time covered by snow on the front of the components. Double-glass bifacial photovoltaic modules are expected to clear the snow on the front of their modules in about 1 to 3 hours.

Compared with single-sided photovoltaic modules, the use of double-glass double-sided photovoltaic modules has increased power generation, and can also effectively reduce the annual solar panel snow removal pressure of photovoltaic power stations and reduce the expenses for solar panel snow removal.

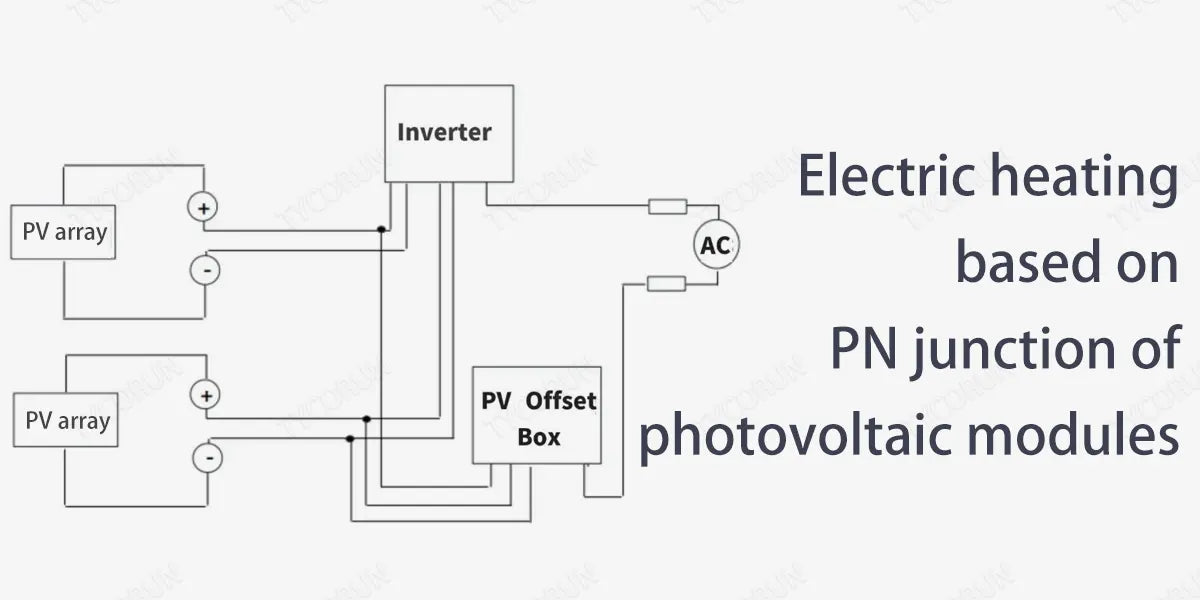

⑦ Snow melting technology based on electric heating principle

When a photovoltaic module is used as a load and a positive voltage is applied to the positive and negative poles of the module, a unidirectional current will be generated due to the PN junction structure inside the module.

The working principle at this time is similar to that of a light-emitting diode LED. Due to the energy level difference of the PN junction and the existence of the resistance of the semiconductor area, when electrons pass through, energy will be generated in the semiconductor area inside the photovoltaic module and converted into heat energy, thereby increasing the temperature of the module and melting snow.

However, in areas with low ambient temperatures, since photovoltaic modules are installed outdoors and the backplane of the photovoltaic modules dissipates heat quickly, the temperature increase using the PN junction electrothermal principle solution is very limited. Therefore, the effect of this solution on melting snow is not obvious, and there are certain problems.

At the same time, an additional external bias power supply is required. One power supply is configured for every 1 to 2 strings, so a large-capacity power station needs to be equipped with multiple units. The investment cost of this solar panel snow removal solution is high and the application is limited.

⑧ Heating cable

The inner core of the heating cable is composed of cold wire and hot wire, and the outside is composed of insulation layer, grounding, shielding layer and outer sheath. After the heating cable is energized, the hot wire generates heat and operates at a temperature of 40℃ to 60℃.

The heating cable is buried in the filling layer. The heating cable transmits heat energy to the heated object through thermal conduction (convection) and 8-13um far-infrared radiation. Distributed photovoltaic power stations can be laid around photovoltaic modules, gutters and downpipes. When there is snow, the heating mode is turned on to quickly melt the snow.

Related posts: solar panel cooling, solar panel wiring, solar panel removal