Data shows that the global market size of rooftop solar panels has reached US$62.4 billion in 2019, and is expected to grow at a compound annual growth rate of 6.9% from 2020 to 2025. The market for rooftop solar panels is expanding year by year, and many people are eager to try it.

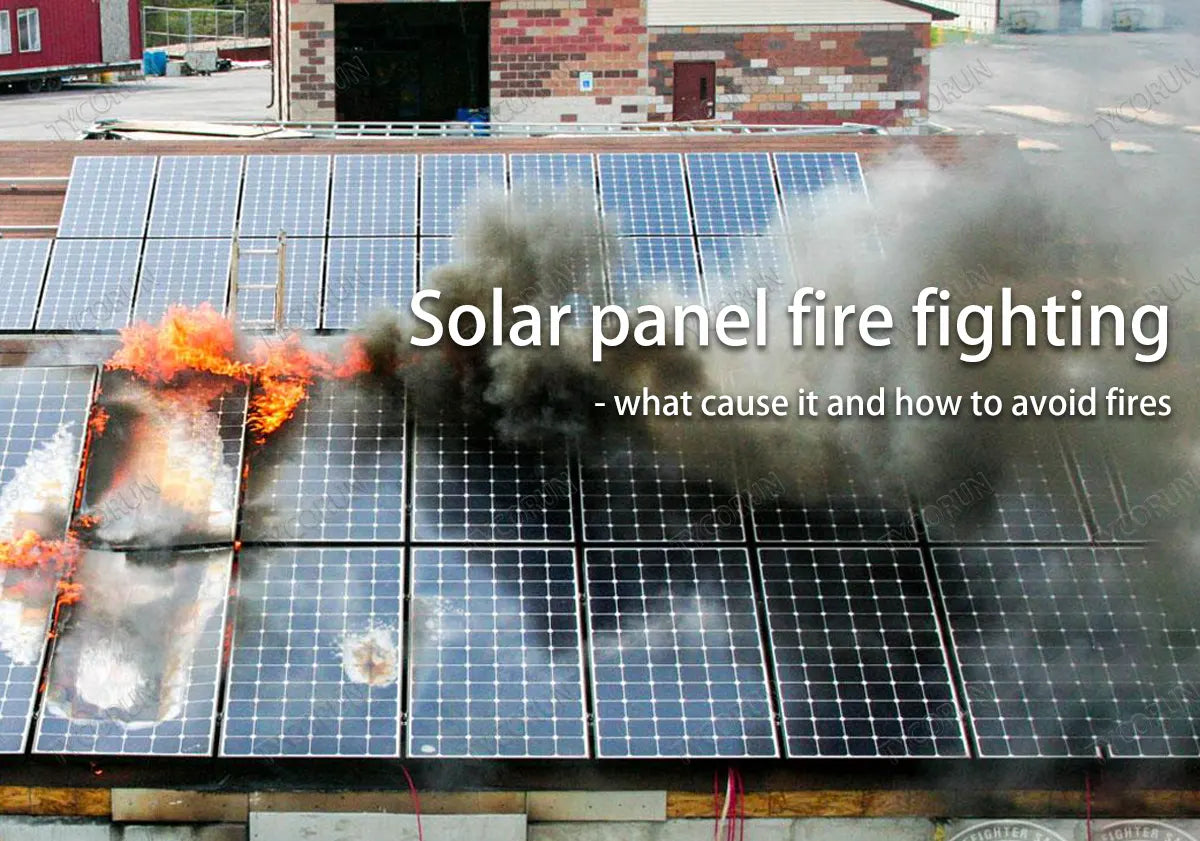

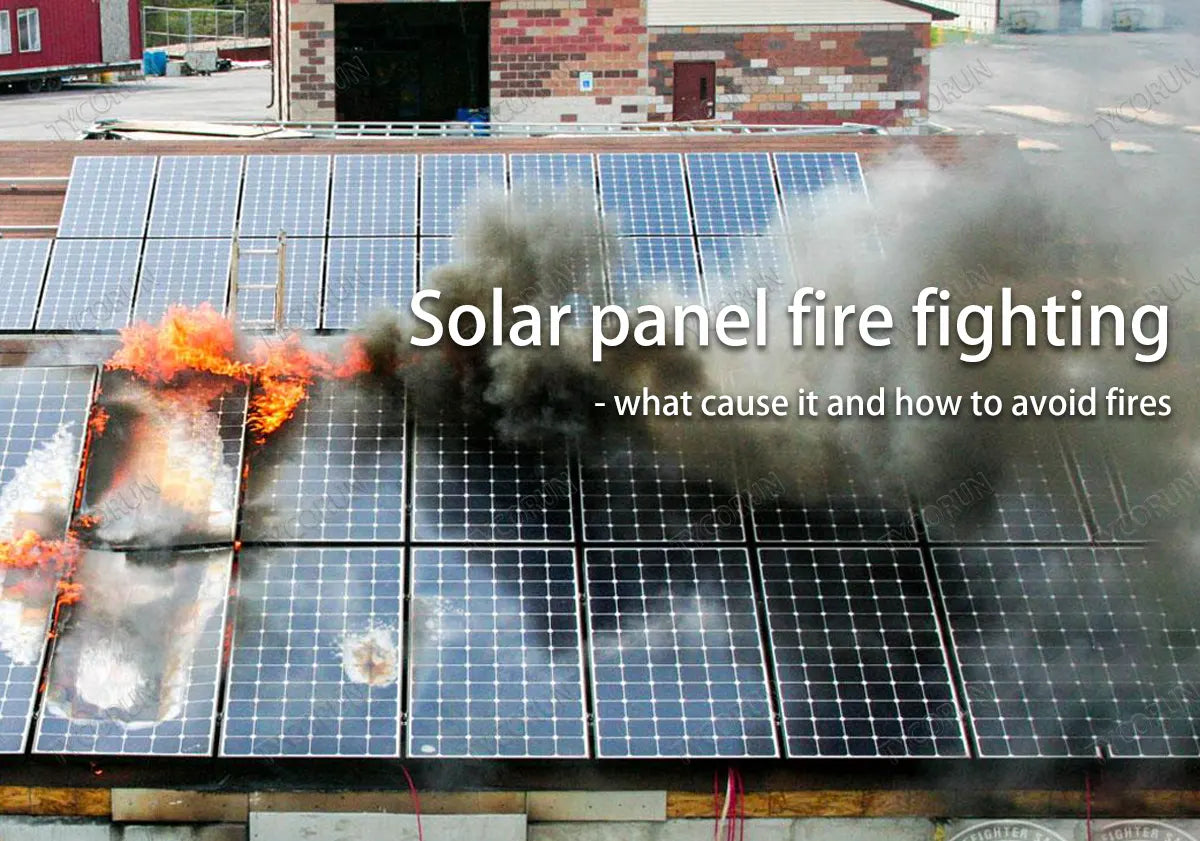

On the other hand, the safety of home solar power system is the factor that stooping people. The fire rate of rooftop solar panels is much greater than that of ground power stations. According to a research by the Clean Energy Association (CEA), more than 90% of roofs present significant safety and fire risks. Distributed power generation application scenarios have more uncertainties.

Solar panel fire has always been the largest economic loss in photovoltaic power plants. Solar panel fire fighting has become the first concern that rooftop solar panel users must know in advance. Only by knowing what causes solar panel fire can they process proper maintenance and detection in daily operation, so as to prevent solar panel fire. This article will provide you with an overall introduction and guide.

Main content:

1. Causes of solar panel fires

The causes of solar panel fires are relatively complex. Here are some common causes.

- High voltage DC arc drawing

The roof area of a 1MW distributed photovoltaic roof is about 7,000 to 10,000 square meters, and there are about 8,000 high-voltage DC connectors. In other words, there is one high-voltage DC connector per square meter on average. Although the probability of arc fire caused by the arcing of DC connector is very low, if the base is large, the probability of fire will be greatly increased.

- Problems with cables on sharp edges

Because cable expansion and contraction are so susceptible to roof vibrations, cables on sharp edges will degrade more quickly. If it is not checked and remedied in time, it can easily cause a ground fault, thereby inducing a potential fire risk.

- Mismatching or improperly manufactured connectors

Rooftop solar modules are usually installed in 18 to 20 modules connected in series and ultimately connected to an inverter such as 2000w inverter or 3000w inverter. The distance from the previous module to the next in these strings is standard, so their harness connections are usually factory-made, but the distance from the end of the string to the inverter is not fixed and often requires "on-site fabrication", directly assembled on site.

But if these on-site fabricated hardware do not have the same modular connectors on the tubes, or are not assembled and installed according to the manufacturer's specifications, they can easily create hot spots that can eventually lead to fires.

- Solar panel rupture

Solar panels made of traditional organic backsheet materials and high-voltage DC power generation systems formed by stacking dozens of solar panels in each channel often have a large number of high-voltage DC cables and connectors directly exposed on the roof. Scratches on the wires will greatly increase the risk of fires. In addition, the crystalline silicon off grid solar batteries are also prone to cracking due to the characteristics of their own crystal structure.

- Hot spot effect

Under cover, hot spots cause the local temperature of components to rise sharply, causing safety hazards and triggering fire accidents. So the government of some places has previously called for regular infrared imaging of photovoltaic roofs because infrared imaging can detect these abnormalities.

It is not hard to find that in addition to possible technical defects in the solar panels themselves, many fire triggers actually come with some human factors. Failure to promptly identify and resolve fire risks is a common feature of the above problems.

With the rapid development of commercial rooftop solar panels, a large number of jobs have also grown. However, there are often problems in the training of practitioners, which in turn leads to installation errors. In addition, since the operation and maintenance of solar panels requires negotiation between the operation and maintenance company and the ultimate owner of the system, there are also certain loopholes in this process.

Annual or biennial inspections are often not well guaranteed, operation and maintenance inspectors should run a system performance test rather than perform a relatively time-consuming line-by-line inspection that can often reveal issues like scratched wires and mismatched connectors mentioned above.

2. Key factors for solar panel fire fighting

There are ten aspects that should be paid attention to when it comes to rooftop solar panel fire fighting:

- Whether the solar power system is designed by a qualified contractor;

- Site survey including dimensions, shadow management, access, slope, orientation and location;

- Roof structure and materials;

- Marking system for all PV equipment, including PV inputs and outputs, conduits, cables, inverters, enclosures, combiners, boxes and isolating switches;

- Roof waterproofing;

- Electrical wiring and grounding systems;

- Array installation and ventilation of the solar panels;

- Mixer boxes and connectors;

- DC/AC inverter;

- DC isolators and other protective devices.

Researchers pointed out that incorrect installation practices are a common factor that contributes to solar panel fire hazards. This situation is caused by the installer's lack of experience or carelessness, but regardless of the reason, it reveals the installer's lack of fire safety knowledge.

The researchers also emphasized the importance of on-site assessments. This move effectively avoids shadow effects and determines the optimal direction of the photovoltaic system's output.

At the same time, ensuring good ventilation conditions around photovoltaic modules is also an effective safety measure, which can well prevent the occurrence of hot spots. In addition, care must be taken to prevent water from penetrating into the housing of the DC isolator.

3. How to prevent solar panel fires

- Set solar panel fire fighting measures according to relevant national or regional fire protection regulations to meet the requirements of national fire protection regulations and reduce compliance risks.

- Manage combustibles based on their quantity, distribution, and combustion characteristics. There are a large number of combustible materials on some roofs and inside the building, and the fire load is very high. The combustible materials should be protected from fire and separated to reduce the fire load. Control the amount of combustible materials at the rooftop, and use non-combustible products as materials for rooftop solar power systems.

- Set appropriate measures of solar panel fire fighting reasonably according to the fire characteristics of the power system. By setting up a fire detection system, fires can be detected in time and valuable time can be gained for solar panel fire fighting.

- Set up corresponding solar panel fire fighting systems according to fire load. When the fire load is large, you can consider setting up an automatic fire extinguishing system to control the scope of the fire in time and gain time for the final solar panel fire fighting.

- Reduce the risk of ignition sources and control ignition sources. Sparks generated by electrical faults in solar power systems are one of the important ignition sources. Choosing high-quality photovoltaic modules, cables, and best solar inverter will effectively reduce the probability of electrical faults.

- Reduce the interaction between photovoltaic power stations and internal fire risks of buildings. Preventing the fire from the photovoltaic power station from spreading to the inside of the building, or preventing the fire from inside the building from spreading to the photovoltaic power station, is very important to reduce the property losses caused by fire.

- Human factors are also an important part of solar panel fire fighting measures. Establishing a good solar panel fire fighting and safety management system will greatly reduce fire losses. Establishing reasonable and effective fire emergency plans, fire interruption management, and fire work management will all play a positive role in fire risk management.

4. Solar panel daily inspection methods

Although the news of various rooftop solar panel fires is shocking, the good news is that these can and are easily avoided. Even checking existing facilities for fire risks and addressing them as quickly as possible is always the most effective approach.

① First, cut off the on-site power supply. Seek professional help and follow proper shutdown procedures to ensure the system is in a safe system shutdown state.

② Then we need to conduct in-depth visual inspection and system shutdown testing. Visual inspections mainly look to see if connectors are mismatched or poorly manufactured, if wires are close to or hanging near the sharp edges, and if the inverter is well terminated. System shutdown testing should include a DC Insulation Resistance Test (DC IRT) and a continuity test that checks for current leakage on the AC cables and ensures that components are properly grounded.

③ Finally, perform system startup checking. After addressing the safety issues identified during the visual inspection and system shutdown testing, we need to re-energize the site and perform maintenance on the components (inverters, field-fabricated connectors, factory-fabricated connectors, load centers, combiner boxes, central and string inverters, etc.) perform system thermal imaging to confirm that the inverter is fault-free and that the monitoring functions are connected and operating normally.

Of course, all of the above measures require a qualified operation and maintenance inspector. Seeking qualified inspectors and installers and ensuring regular maintenance and inspections can minimize the chance of a rooftop solar panel fires.

Related posts: global top 10 best solar inverter brands, working principle of inverter, inverter cooling