New energy storage systems play an important role in the process of energy structure innovation. As a new force in the field of energy storage, sodium-ion batteries are of great significance to energy storage systems, especially energy storage on the power generation side. To this end, this article lists 12 FAQs about sodium-ion batteries for your reference.

Main content:

- Does sodium ion perform better at low temperature? Is it really possible to reach 160wh/kg?

- What are the main factors affecting the cycle life of sodium ion batteries?

- If the cathode and anode materials are replaced, will the cost of replacing lithium with sodium ions drop?

- Are there currently any sodium-ion battery companies with leading technology?

- Hina Battery has developed a sodium battery with an energy density of 145wh/kg and a cycle life of more than 4,500 times?

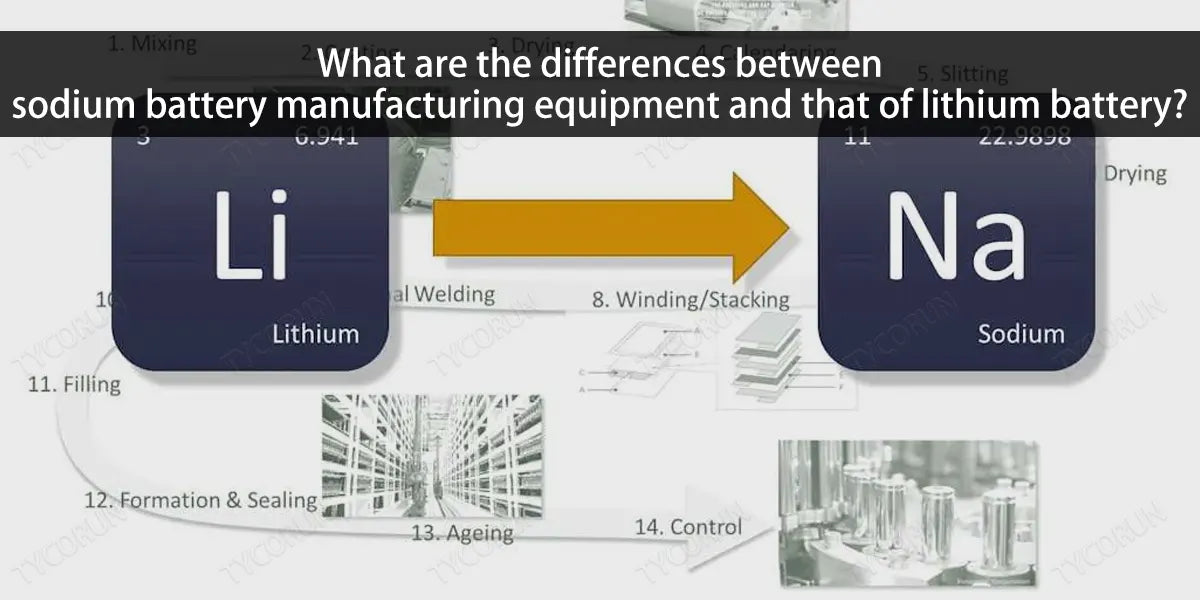

- What are the differences between sodium battery manufacturing equipment and that of lithium battery?

- If sodium ion batteries are made into solid state, how much can the energy density be increased?

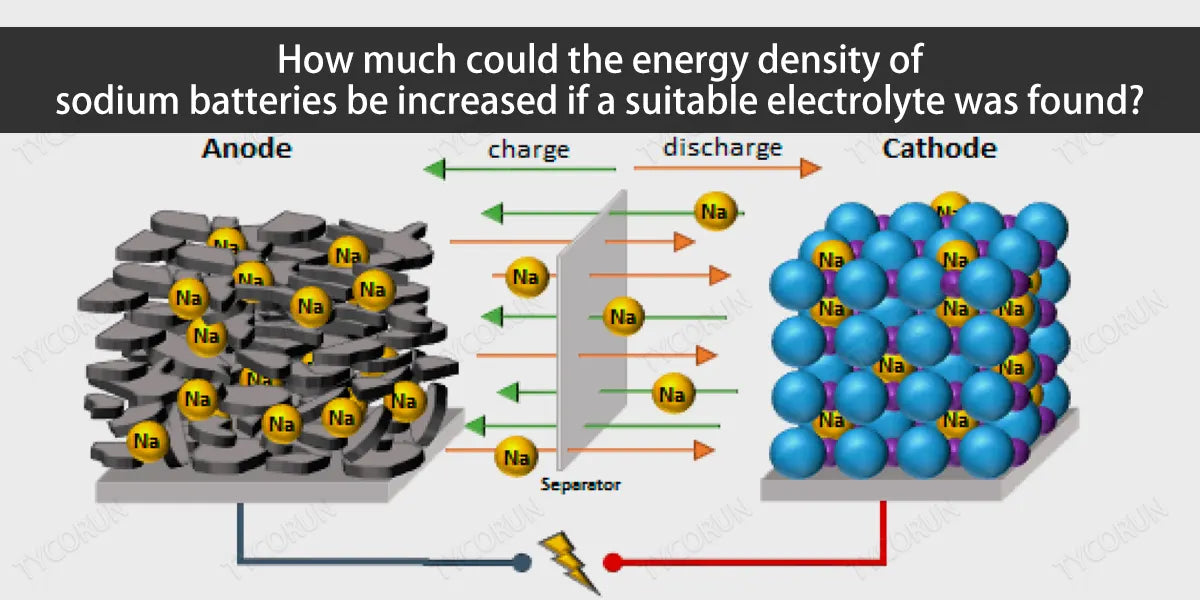

- How much could the energy density of sodium batteries be increased if a suitable electrolyte was found?

- What is the current development status of sodium-ion batteries in the world?

- When sodium ion technology matures, what proportion of the total installed battery capacity will it account for?

- Which one can develop faster and more maturely, sodium ion batteries or fuel batteries?

- Will sodium-ion batteries and lithium-ion batteries coexist?

1. Does sodium ion perform better at low temperature? Is it really possible to reach 160wh/kg?

Sodium ion batteries can operate normally between -40℃ and 80℃ and have good wide temperature characteristics. The high-temperature discharge capacity (55℃ and 80℃) exceeds 100% of the rated capacity, and the low-temperature (-40℃) discharge capacity exceeds 70% of the rated capacity.

Sodium ion batteries can achieve 0.1C charging at -20℃, and its charging efficiency is close to 100%. The low-temperature performance surpasses lithium iron phosphate batteries and lead-acid batteries. At a temperature of -20℃, the capacity retention rate of sodium ion batteries is as high as 90%, while lithium iron phosphate batteries and lead-acid batteries can only reach 70% and 48%. 160wh/kg fast charging can theoretically provide 80% power in 15 minutes.

2. What are the main factors affecting the cycle life of sodium ion batteries?

- Stability of the cathode material: The stability of the cathode material directly affects the cycle life of the battery. Some sodium ion embedded materials will undergo structural changes during the charge and discharge process, resulting in capacity attenuation and cycle life reduction;

- Stability of anode materials: The stability of anode materials is also an important factor affecting cycle life. Sodium metal easily forms sodium branches during the charge and discharge process, causing an internal short circuit in the battery and thus affecting the cycle life;

- Stability of the electrolyte: The stability of the electrolyte also has a great impact on the cycle life of the battery. Some organic solvents will decompose during the charge and discharge process, causing the internal pressure of the battery to increase and thus affecting the cycle life;

- Charge and discharge conditions: Charge and discharge conditions are also important factors affecting cycle life. Too high or too low charging current density, too high or too low charge cut-off voltage, too high or too low discharge cut-off voltage will all affect cycle life.

3. If the cathode and anode materials are replaced, will the cost of replacing lithium with sodium ions drop?

At present, sodium ion batteries have not yet been mass-produced, and the material cost is higher than that of industrialized lithium ion batteries. However, after mass production, the entire production process will be the same as that of lithium batteries, and the cost can be reduced by about 50%. However, the cathode and anode materials have not yet been determined, so it is hard to estimate accurately.

Compared with lithium-ion batteries, the cost advantage of sodium-ion batteries mainly lies in the cathode, because the performance of manganese in terms of metal ions in the cathode is more stable.

Adding elements such as nickel or cobalt-iron to a system based on sodium-manganese oxygen will not be too expensive, while lithium-ion batteries are all made of high-nickel, which requires a lot of cobalt and nickel, and the cost is much higher than manganese. If too much manganese and oxide manganese are used in lithium batteries, the performance will be very poor.

However, manganese can be used as a large amount of stabilizing element in sodium-ion batteries. There is no need for nickel and cobalt. Manganese is used as the main metal element combined with sodium carbonate to form a stable element after mass production. So the production cost will be significantly lower than that of current lithium batteries.

4. Are there currently any sodium-ion battery companies with leading technology?

Among mainstream companies, CATL has a team to make sodium-ion batteries. They have also released news on their existing sodium-ion batteries, and their technology is relatively advanced. In addition, many universities are now engaged in relevant research and development.

For example, the Chinese Academy of Sciences incubated Hina Battery, which specializes in sodium-ion batteries. Shanghai Jiao Tong University incubated Natrium Energy in Shaoxing, which mainly produces energy storage batteries that work with inverters like power inverter 3000w or 2000w inverter. It is also a start-up sodium-ion battery company.

CATL has only done some research and development on sodium. Current sodium-ion batteries are not yet mature. Although CATL expects to mass-produce them in next 1-2 years, their sodium battery products are still in the laboratory stage.

5. Hina Battery has developed a sodium battery with an energy density of 145wh/kg and a cycle life of more than 4,500 times?

The cycle life depends on many conditions. Generally speaking, 2,000 cycles will be ideal, but if the charge and discharge are within the range of 80%, it can reach 3,000-4,000 times. The cycle life depends on the charging cut-off voltage, because if the cut-off voltage increases by 0.1v, its cycle life will decrease a lot.

Hina Battery's cathode material is based on a sodium-manganese-oxygen system that is doped with elements such as copper, iron, and cobalt. The anode uses a hard carbon electrolyte, which should be sodium hexafluorophosphate.

6. What are the differences between sodium battery manufacturing equipment and that of lithium battery?

The material manufacturing equipment is almost the same, just the raw materials are changed. The ternary materials of lithium batteries or lithium cobalt oxide are invested in the cathode material production line using engineering electricity and solid-phase methods. The raw materials are mainly lithium carbonate, nickel oxide, benzene or metal salt plus lithium carbonate or lithium sodium hydroxide. You can click for the best LFP battery, or check battery stores near me.

For metal salts, the same thing is to replace lithium carbonate or lithium hydroxide with sodium carbonate and sodium hydroxide, but the entire synthesis process is the same. For cathode manufacturers, they can basically use the current lithium battery cathode production equipment, there are some adjustments to the production parameters and conditions, but the equipment is basically the same.

The difference in graphite is not too big, either, and the electrolyte is basically similar. The only difference is that the dissolved lithium hexafluorophosphate is replaced by sodium hexafluorophosphate, but it is not much different from the entire lithium battery production line.

7. If sodium ion batteries are made into solid state, how much can the energy density be increased?

Sodium-ion solid-state batteries actually have little advantage. On the one hand, its technological maturity is currently relatively low. The main problem is that the solid-state electrolyte of sodium batteries is not particularly good, which is also a barrier that current solid-state batteries need to break through. Or replace the electrolyte with a solid electrolyte could be another solution.

However, there are no particularly good cathode and anode materials for solid electrolytes. Nowadays, layered materials or hard disk materials are more commonly used. However, the volume ratio of sodium ions is large, and it is more difficult to migrate in the solid, its ionic conductivity is relatively poor among electrolytes, so if battery companies want to make a solid-state sodium battery, they must first increase the ion mobility.

8. How much could the energy density of sodium batteries be increased if a suitable electrolyte was found?

If it cannot reach 200wh/kg, then its improvement in liquid sodium-ion batteries is very limited. The electrolyte accounts for more than 20% of the weight of the battery. If it is all made into solid state, it can be made very thin if done well, and the entire energy density can also be optimized. However, the solid electrolyte cannot be made very thin because there is a risk of short circuit. If it is made thicker, the energy density will be reduced.

Today's sodium batteries are not very mature, so the performance of solid-state batteries is still far lower than that of liquid sodium-ion batteries. Liquid sodium ion batteries can produce 90%-100% of the energy, but in the solid state they may only be able to use 60%-70%, because it involves the migration of ions in the solid, and the electrolyte can penetrate into the cathode and anode.

The particles of cathode and anode materials can be in contact with the electrolyte, but there must be an ion transmission channel in the solid, while this may cause the particles to be out of touch in the cathode and anode. The utilization rate will be compromised, and the increase in energy density will be limited.

9. What is the current development status of sodium-ion batteries in the world?

There are some research projects in the United States and Europe. The United States now has some research and development projects dedicated to sodium-ion batteries. However, the research and development progress of sodium-ion batteries in the United States still lags behind that of China and South Korea.

There are several start-up companies in the United States that also want to industrialize sodium-ion batteries, but their scale and technology are not yet large. South Korea's LG, Samsung and SKI are also making plans, and their progress is similar to that of Chinese companies.

10. When sodium ion technology matures, what proportion of the total installed battery capacity will it account for?

The technical disadvantage of sodium ion is that its energy density is lower than that of lithium-ion batteries. Its applications are mainly focused on energy storage like home battery storage and electric mobility tools that do not require high energy density, such as low-speed electric vehicles and electric buses.

Therefore, if the technology of sodium-ion batteries matures, its market share in the energy storage field can exceed 50%. However, in terms of power batteries, it is difficult for sodium-ion batteries to occupy a relatively high market share, and it is expected to reach 20% at most.

11. Which one can develop faster and more maturely, sodium ion batteries or fuel batteries?

From the perspective of technological maturity, it may be more optimistic about sodium-ion batteries, because the process is very similar to lithium-ion batteries, and lithium-ion batteries are already very mature, so the process of promoting mass production of sodium-ion batteries will be very fast, and the related industrial chain can also be built up.

However, the large-scale production and application of fuel batteries is still relatively long way to go. Fuel batteries are the ultimate goal to solve energy problems because the reaction of hydrogen and oxygen is very clean and the energy density is also high. However, the current bottleneck is the storage and release of hydrogen and the problem of precious metal catalysts in batteries, which makes it difficult to reduce the cost and find alternative catalyst technologies.

Therefore, these two technical bottlenecks are difficult to overcome in the short term. It may take decades for fuel battery technology to get truly mature.

12. Will sodium-ion batteries and lithium-ion batteries coexist?

The odds are high. Because each technology has its own characteristics and application scenarios, lithium batteries, fuel batteries, and sodium batteries all have different technologies and targeted scenarios, so the possibility of coexistence is very high.

Also lead-acid batteries will not withdraw from the market. The current mass production and application of lead-acid batteries are growing every year, but the growth rate is not as fast as that of lithium batteries.

Related posts: 12 volt 100ah deep cycle lithium battery, 12v 200ah deep cycle battery, power wheels battery