Main content:

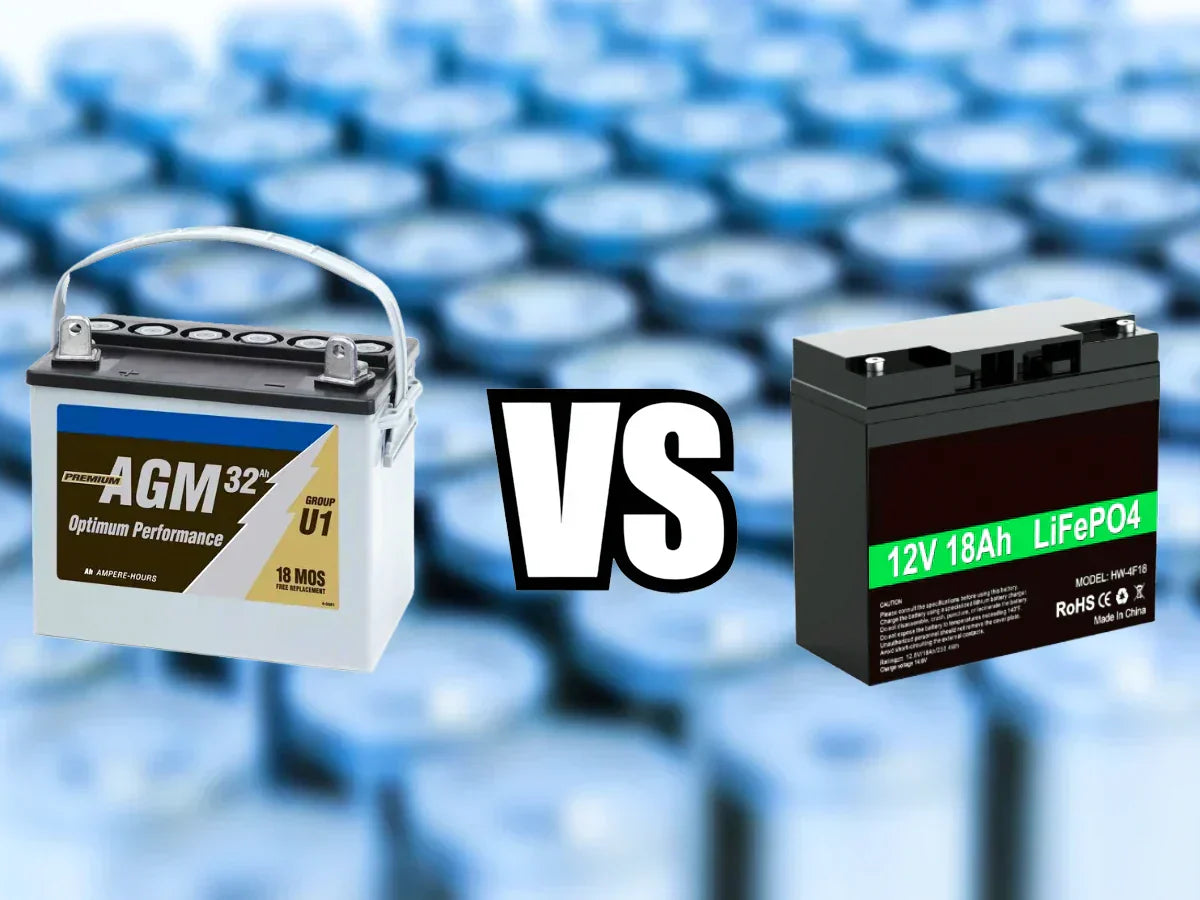

AGM battery vs. lithium technologies are widely debated in energy storage and vehicle applications. AGM batteries, as a mature lead-acid solution, offer proven reliability, strong short-term current output, and lower initial cost. In contrast, lithium batteries offer higher energy density and longer cycle life, but require advanced management systems. Understanding their differences is key to optimal application.

Working Principle of AGM Batteries

During discharge: The lead dioxide on the positive plate and the spongy lead on the negative plate react with sulfuric acid in the electrolyte to form lead sulfate, reducing the sulfuric acid concentration in the electrolyte.

During charging: The lead sulfate reverts to lead dioxide and spongy lead through redox reactions, respectively, increasing the sulfuric acid concentration in the electrolyte.

Features of AGM Batteries

Valve-Regulated Design

AGM batteries utilize a colloid valve design, which prevents gas generated by the battery from immediately escaping. Instead, it undergoes an efficient oxygen recombination reaction internally, reducing water loss and extending battery life. Gases are released only when the internal pressure reaches a certain level. This feature is often highlighted when discussing AGM battery vs. lithium.

AGM Separator

AGM separators eliminate the flow of acid within the battery, reducing acid stratification. High-strength AGM separators maintain optimal homogeneity, ensuring a tight battery assembly while securing the active material to the grid, preventing it from falling off and improving the battery's cycle life.

Approximately 10% of the separator's porosity serves as an oxygen recombination channel, achieving an oxygen recombination efficiency exceeding 98%, minimizing water loss. AGM separators also minimize acid stratification, preventing OCV-SoC mismatch, reducing excessive sulfate formation, preventing premature battery failure, and improving charge acceptance.

Low-Liquid Design

Due to internal oxygen recombination, AGM batteries minimize water loss during use, eliminating the need for space above the plates. This design increases the plate height, thereby increasing the plate surface area. This gives AGM batteries improved starting performance and charge acceptance for the same size and number of plates.

Advantages of AGM Batteries Compared to Lithium Batteries

Mature Technology and Wide Applications

AGM batteries are a mature lead-acid technology, proven in decades of industrial application and widely used in marine, power storage, UPS, and vehicle applications. Users have easy access to reliable installation and maintenance solutions, and the technology is highly mature and low-risk—a major factor in AGM battery vs. lithium evaluations.

Stable Low-Temperature Performance

AGM batteries offer relatively stable battery performance in low-temperature environments, especially in starting or backup power scenarios. They can still provide usable current at low temperatures, making them suitable for certain low-temperature operating environments.

High Short-Term High-Current Capacity

AGM batteries have excellent instantaneous starting capability, capable of delivering high current for a short period of time. This makes them suitable for starting loads or scenarios with sudden high power demands, such as vehicle ignitions and backup generator startups.

Safety and Fault Tolerance

AGM batteries utilize a valve-regulated seal design, allowing internal gases to recombine to form water, reducing maintenance requirements while preventing fluid leakage and acid spread, resulting in high safety. Compared to lithium batteries, which require stringent BMS, temperature control, and charging management, AGM batteries are less reliant on management systems. This aspect is often highlighted in AGM battery vs. lithium debates.

Relatively Low Price and Initial Investment

The initial purchase cost of AGM batteries is lower than that of lithium batteries, making them particularly cost-effective for projects requiring large-capacity battery packs. They are suitable for budget-constrained or short-term investment recovery scenarios.

Low Charging Equipment Requirements

AGM batteries can use conventional lead-acid chargers and have less stringent charging environment requirements than lithium batteries. They do not require complex BMS protection or strict temperature compensation.

Check AGM battery vs lead acid for more information.

| Feature | AGM Battery | Lithium Battery |

|---|---|---|

| Technology | Mature lead-acid (Absorbent Glass Mat) | Advanced lithium-ion or LiFePO4 |

| Energy Density | Lower, heavier | Higher, lighter |

| Lifespan | 3-5 years | 8-15 years |

| Maintenance | Minimal, but sensitive to deep discharge | Low, protected against deep discharge |

| Cost | Lower upfront | Higher upfront |

| Temperature Performance | Stable in low temperatures | Can degrade in extreme cold or heat |

| Charge Speed | Slower | Faster |

| Applications | UPS, vehicles, marine, backup power | EVs, solar storage, portable devices |

Installation and Maintenance Comparison: AGM vs Lithium

Installation Requirements

AGM Batteries

When installing, ensure that the AGM battery is tilted no more than 40°. Never place it upside down or sideways to prevent damage to the internal structure or electrolyte leakage. When installing, place it gently into the mounting base to avoid impact that could cause cracking of the battery casing. Before placing the battery, inspect the tray for foreign objects such as screws and nuts to prevent scratches on the battery casing.

During installation, do not install batteries with a voltage below 12.7V. If the voltage is insufficient, recharge the battery first. Batteries with cracks, swelling, leakage, or other damage should not be used. When connecting cables, strictly follow the positive terminal first, then the negative terminal. When removing, follow the negative terminal first, then the positive terminal. Avoid striking or twisting the terminals during installation to prevent loosening or poor contact.

Lithium Batteries

Lithium batteries also require secure placement during installation. Although they do not contain liquid electrolyte, placing them upside down or sideways can cause structural stress, loose connectors, or damage the battery management system (BMS). Before installation, inspect the tray and mounting base to ensure they are clean and free of foreign objects to prevent external forces from damaging the battery casing. It is recommended that the battery be installed with a charge level of at least 30%.

Excessively low charge may trigger a protection mode, preventing the device from starting. Batteries with bulging, deformation, or abnormal BMS alarms should not be used. When connecting the terminals, follow the positive terminal first, then the negative terminal; remove them in the opposite order. Some smart lithium batteries require BMS activation or calibration after installation to ensure proper function.

Storage Requirements

AGM Batteries

During storage, AGM batteries must be in good condition, fully labeled, and have a voltage above 12.7V. They should be stored away from heat sources, in a cool, dry, and well-ventilated environment. Do not store them upside down or horizontally. External short circuits must be prevented during storage, and inventory management must adhere to the "first-in, first-out" principle.

When the ambient temperature drops below -15°C, batteries should be stored in warm storage. Voltage must be checked before storage, and recharged if it falls below 12.7V. During storage, the voltage must be checked every seven days, and recharged if it falls below 12.7V. Furthermore, batteries must be recharged every three months using a dedicated AGM charger to ensure stable performance.

Lithium Batteries

Storage requirements for lithium batteries are less stringent, but they must also be in good condition, free of swelling or damage. During storage, it is recommended to maintain the battery charge between 30% and 60%. Avoid prolonged storage in a fully charged or over-discharged state to extend the cycle life. The optimal storage temperature is 15-25°C, away from high temperatures and direct sunlight.

Lithium batteries can be stored horizontally or vertically, but external pressure and short-circuiting of the terminals must be avoided. Due to their low self-discharge rate, the voltage should generally be checked every 3-6 months. When the voltage falls below the protection threshold, a recharge is required. Frequent recharging is not required during long-term storage; simply maintain an appropriate charge level. Storing at a full charge is not recommended.

Maintenance of Inventory and Display Vehicles

AGM Batteries

All new vehicles must have their battery voltage checked before entering storage to ensure it is above 12.7V. If it falls below this value, a recharge is required. When inventory or display vehicles are parked for more than three days, the negative terminal of the battery should be disconnected to prevent static power consumption in the electrical system, which could cause a battery failure.

Even if the battery is disconnected, the voltage should be checked every seven days. If it falls below 12.7V, a recharge is required. Before a vehicle leaves the warehouse, inspect the battery for secure installation, leaks, cracks, or dirt, and ensure normal voltage. Jump-starting a depleted battery is strictly prohibited before directly delivering it to a customer. Furthermore, if the battery has been parked for more than three months, if the vehicle is leaking, or if the generator is charging abnormally, the battery must be recharged.

Lithium Batteries

When lithium batteries are used in display and inventory vehicles, the battery charge level should be checked to ensure it is within the appropriate range (30% to 80%) upon entry. If the vehicle is expected to be parked for more than a week, disconnect the BMS or remove the negative terminal to reduce static power consumption.

Compared to AGM batteries, lithium batteries do not require weekly recharging; generally, an inspection every one to two months is sufficient. Before leaving the warehouse, inspect the battery for normal appearance, any abnormal BMS alarms, and normal communication. Jump-starting a depleted lithium battery is not recommended, especially for batteries with a protective board, as this may damage the protective circuitry.

Recharging Requirements

AGM Batteries

Recharging AGM batteries must be performed in a well-ventilated environment and away from open flames. When wiring, connect the positive terminal first, then the negative terminal. If a wire is broken, connect the negative terminal first, then the positive terminal. Batteries with cracked, swollen, or abnormally heavy casings must not be recharged and must be replaced. Before recharging, clean the terminals and remove the oxide layer. After charging, apply butter to the terminals to prevent corrosion.

A charger with a constant voltage of 14.4 ± 0.2 V and a maximum current of 0.2C 20A is recommended. When the current drops below 1A, the battery is fully charged and charging should be stopped immediately. If the battery temperature rises or acid mist is emitted during charging, immediately reduce the current or stop charging and wait until the temperature returns to normal before resuming.

Lithium Batteries

Recharging lithium batteries must also be performed in a safe, well-ventilated environment, and ensure that the charger is compatible with the battery type. A dedicated charger with constant current and constant voltage (CC/CV) function must be used to avoid safety risks caused by overcharging.

Lithium batteries generally do not require frequent recharging, but if the charge level drops below the BMS protection threshold, an activation charge is required. Batteries with swollen, deformed, or abnormally high temperatures should not be charged during recharging. If the temperature rises too high during charging, the system will automatically reduce the current or stop charging to protect the battery.

Maintenance Frequency and Failure Detection Comparison

AGM Batteries

AGM batteries require a higher maintenance frequency. Voltage checks should be performed every seven days, and batteries should be recharged regularly to prevent sulfation caused by prolonged battery depletion.

Once sulfation occurs, capacity will decrease significantly, and batteries may even become useless. Replacement is also necessary if the casing exhibits cracks, bulging, leakage, or terminal corrosion(how to clean battery corrosion). AGM batteries are temperature-sensitive, and high temperatures accelerate water loss and aging.

Lithium Batteries

Lithium batteries require less frequent maintenance; voltage checks are typically performed every three to six months. Sulfation is not a concern. Key concerns include high-temperature aging, cell swelling, abnormal BMS alarms, or capacity decay.

Replacement is necessary if the battery exhibits significant swelling, severe capacity loss, or a failure of the protective circuit board. Lithium batteries, with BMS protection, effectively prevent risks such as overcharging and over-discharging, reducing the need for manual maintenance.

Maintenance requirements are a major factor in AGM battery vs. lithium decision-making.

Conclusion

AGM batteries remain a cost-effective, safe, and robust option for environments requiring stable, high-current output and frequent maintenance tolerance. While lithium batteries excel in energy density and lifecycle, AGM technology’s mature design and low equipment requirements make it ideal for traditional applications where reliability and simplicity are prioritized.

FAQs

What are the disadvantages of AGM batteries?

Although safe and reliable, AGM batteries have low energy density, are bulky, and heavy, making them unsuitable for applications requiring lightweighting. Their capacity decreases significantly during high-load discharge, and their charging efficiency is low. They are also temperature-sensitive, with high temperatures accelerating aging and moisture loss, requiring frequent maintenance.

What happens if you charge a lithium battery with an AGM charger?

Charging a lithium battery with an AGM charger may cause overvoltage or overcurrent, triggering the battery management system (BMS) protection and even damaging the battery cell or protective circuit board. Lithium batteries require a dedicated constant-current and constant-voltage charger to ensure controlled charging current, voltage, and temperature; otherwise, safety risks may arise.

What is the lifespan of an AGM battery?

The lifespan of an AGM battery is affected by the number of cycles, depth of discharge, and operating environment. Typically, a battery can cycle approximately 300 to 500 times at a 50% depth of discharge. High temperatures, frequent deep discharges, or prolonged periods of battery drain can significantly shorten its lifespan. Regular maintenance and recharging can extend its lifespan.

Can I add distilled water to an AGM battery?

AGM batteries feature a sealed valve-regulated design, with the electrolyte trapped within the separator. Under normal use, adding water is not necessary. If the battery swells or leaks, it indicates a problem and should be replaced. Adding water may damage the internal structure, affecting performance and compromising safety.