Main content:

With the continuous improvement of the cruising range of new energy vehicles, lithium batteries are still market-leading. Lithium battery technology has attracted much attention.

Exploring lithium battery technology can effectively help enterprises and market development faster. The development of lithium battery technology began in the consumer field and is currently developing rapidly in the field of power and energy storage.

1. Lithium battery technology route

Lithium ion batteries refer to secondary batteries (rechargeable batteries) that use lithium as an energy carrier. During charging, lithium ions exit the anode, pass through the electrolyte and separator.

And are embedded in the cathode. Discharge occurs in the opposite process, also known as the rocking chair battery. Lithium ion batteries are divided into lithium iron phosphate batteries and ternary lithium batteries according to different cathode materials.

Lithium iron phosphate materials are rich in production resources, and the cost, cycle life and thermal stability are better than ternary materials. It is suitable for commercial vehicles, low-end passenger cars, energy storage and other fields.

The theoretical specific capacity (energy density) of a ternary lithium battery is 60% higher than that of lithium iron phosphate, the charging rate is higher. Additionally, the 18650 rechargeable battery, which are known for their high performance, are less likely to be damaged by low discharge. And the low temperature performance is good, which makes it suitable for medium and high-end passenger cars and other fields.

2. Power lithium battery technology route

Lithium ion batteries are divided into prismatic batteries, pouch batteries and cylindrical batteries according to the different packaging processes of lithium battery technology routes.

The advantages of prismatic batteries are high packaging reliability, simple structure, high energy density of monomers, high system group efficiency, and relatively good stability. But the disadvantages are that there are many models, the process is difficult to unify, and the monomer is very different, so that the system life is lower than the monomer life.

The pouch battery is packaged in aluminum plastic film through lithium battery technology. The advantages are high energy density, small internal battery pack, long cycle life.

The disadvantage is that high-end aluminum plastic film relies on imports and has low production efficiency and low yield. The reliability of cylindrical battery hard shell packaging is high. The advantages are high battery consistency, a mature process, low cost.

Those better battery product yield and better heat dissipation performance. Nevertheless, the disadvantage is that the heat dissipation design is difficult after grouping, and the system energy density is low.

3. Energy storage lithium battery technology route

Lithium iron phosphate power batteries return to dominance. The advantages of lithium iron phosphate in terms of cost and safety have gradually emerged, and the installed capacity of the market has risen rapidly, and the market proportion has increased year by year.

China's installed power battery capacity has maintained a rapid growth trend and the lithium battery technology has been developed, with an average compound annual growth rate of 49% by 2025.

Power lithium battery technology direction

In terms of high safety, the safety performance of battery cells is mainly improved by using three methods: ontology safety, process safety, and fire safety. Ontology safety relies primarily on flameretardant and noncombustible electrolytes, highmelting separators, and cathode material modification and coating to improve battery ontology safety.

Power battery safety prevention technology

In terms of long life, the service life of lithium iron phosphate batteries is generally higher than that of ternary batteries. The service life of lithium iron phosphate blade battery is more than 5000 times, followed by ternary pouch battery, with a service life of more than 3000 times, again a prismatic battery, with a service life of more than 2000 times, and a cylindrical battery with a slightly lower service life, about 1000 times.

In terms of fast charging performance, the ternary battery rate is developing from the current 2C to 5C rate, and the charging time is shortened by 60%. A number of companies are improving the speed of ternary battery replenishment. What’s more, they improve the fast charging performance of batteries by improving the charging voltage and the tolerance of high current of the battery through the lithium battery technology.

Energy storage battery technology is mainly used in large-scale energy storage (power system energy storage), communication system energy storage, home energy storage and portable energy storage.

Large-scale energy storage is the main application scenario of energy storage batteries, which are mainly used for energy storage assembly systems on the power generation side, grid side and user side. Energy storage batteries are in a stage of rapid development, and the market pattern is uncertain.

The development trend of energy storage cell products is product standardization, large battery cells, and de-modularization. Companies are entering the industry and trying to get bigger and stronger. Lithium iron phosphate batteries have become the mainstream route Lithium battery performance requirements include energy density, power density, cost, life and safety.

Energy storage applications have relaxed battery energy density and power density requirements, and more emphasis has been placed on reducing the cost of distributing and storing electricity. Energy storage batteries need to have low cost, long life, and ensure the safety of battery applications.

Ternary lithium batteries have high energy density and power density, but the cost is high and the safety is relatively weak. Lifepo4 batteries have excellent safety, long cycle life, abundant metal resource reserves, low cost and environmental protection, and have become the main choice for stored energy batteries.

Energy storage lithium battery technology direction

- Large-scale energy storage technology

Large-scale energy storage system is an important facility to promote the large-scale application of renewable energy and build a new power system, which can play a role in peak shaving, frequency regulation, backup capacity, smooth output, and alleviate grid congestion.

It includies the power generation side, grid-side energy storage, etc., usually in tens or even hundreds of MWh. The use of cells is mainly large-capacity square cells. The development trend of large batteries for power storage is obvious.

- Household storage technology direction

Household scenarios have relatively low requirements for battery energy density, and the main impact on the user experience is the overall product design, including battery management and whole-house energy allocation. Moreover, the requirements for battery cell performance are relatively relaxed, mainly emphasizing safety and cost reduction. Soft bags, cylinders, etc. can become the choice of household storage cells. Small batteries may become the mainstream of household storage.

The home storage market is undergoing product integration from low voltage to high voltage systems. The high voltage platform reduces the current, thereby controlling the heat generation of the system and improving discharge efficiency.

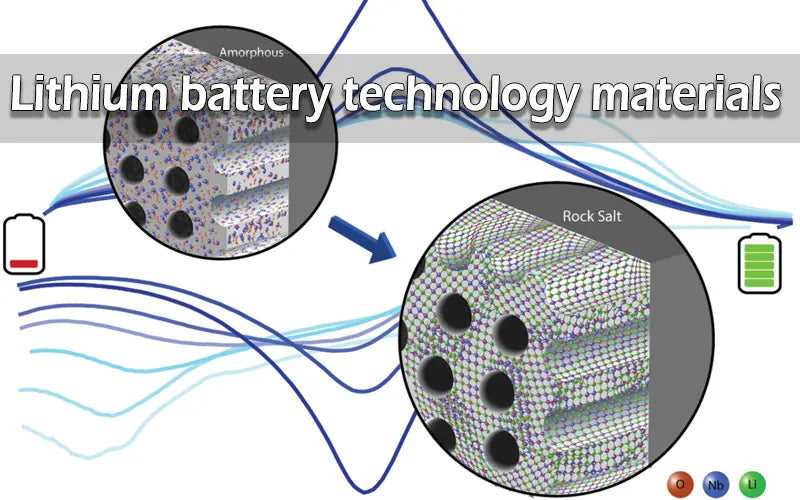

4. Lithium battery technology materials

Lithium battery technology cathode material

Cathode materials are the most important cost, accounting for about 55%. Lithium ion batteries are mainly divided into lithium iron phosphate batteries and ternary batteries with different cathode materials, power batteries have both.

And energy storage batteries are almost all lithium iron phosphate batteries. The lithium battery technology has gained much attention on the market.

- Electrolyte

Electrolytes account for about 13% of the total cost, and their main components are solutes, solvents and additives.

- Copper foil lithium battery

Lithium ion copper foil is electrolytic copper foil, accounting for about 8% of the cost. Lithium battery copper foil is used for lithium battery anode current collector.

- Diaphragm

Diaphragms account for 4% of the total material cost and are divided into wet and dry diaphragms. The main cost of wet diaphragm is PE and dry diaphragm The principal component is PP.

Lithium iron phosphate is developing in the direction of high pressure, low temperature performance and high energy density. Ternary materials are developing in the direction of high nickel, low cobalt, single crystal, quaternary, etc. And are also exploring the direction of technological development such as solid-state lithium battery materials, in order to further improve the energy density and fast charging performance of batteries.

Lithium battery technology anode material

Anode materials account for about 14% of the total cost, including artificial graphite and natural graphite. Artificial graphite can be used in power batteries and energy storage batteries, while natural graphite is mostly used in consumer batteries. At the same time, it is the mainstream anode material and occupies a large market share. The top 10 lithium ion battery anode material companies are all focus on this filed.

Silicon-based materials combine the high conductivity and stability of carbon materials with the high capacity of silicon materials. At present, silicon-based materials are used in cylindrical power batteries.

Due to the immaturity of silicon-based material technology and the limitations of the lithium battery technology, the problem of silicon volume expansion has not been solved. Also, the preparation process is difficult and non-standard, and the price is expensive, which is currently mainly used in high-end cylindrical power batteries.

- Electrolyte

The new lithium salt has the possibility of steady improvement in the future. New lithium salts and additives can effectively improve battery cycling and high and low temperature performance, which is the main strategy for the differentiated development of electrolyte products.

LiPF6 is still the most important lithium salt in the short term, but the penetration rate of new lithium salts such as LiFSI is expected to gradually increase. LiPF6 has poor thermal stability and sensitivity to moisture.

However, there are problems such as easy HF generation. The development of new lithium salts has become an important direction for electrolyte research and development. LiFSI has the advantages of high and low temperature performance and good thermal stability, and is currently developing rapidly.

- New lithium salt

With the development of lithium batteries in the direction of high voltage and high nickel, the required electrolyte formula, especially the use of additives, will become more and more complex. The use of additives in small amounts can significantly improve the performance of the electrolyte, so the cost performance is very high. The future will be the key to further enhance the competitiveness of enterprises and improve the added value of products.

- New additives

Lithium battery copper foil With the rapid growth in demand for power batteries, the total shipment of copper foil for lithium batteries will increase significantly.

- Diaphragm

The diaphragm is divided into wet diaphragm and dry diaphragm, and the wet diaphragm occupies the dominant market position with the advantages of light and thin, low self-discharge and so on. The thickness of the wet separator is lower than that of the dry separator, which is conducive to improving the energy density of the battery.

The main advantages of dry diaphragms are low cost, overcharge resistance and high safety. The diaphragm is difficult because of its substrate, coating paste and process. Its difficulty mainly comes from raw material selection and proportioning, diaphragm equipment and precise control technology, among which new diaphragm substrates and coated diaphragms have become the key research and development directions.

- New diaphragm substrate

Battery rate and safety can be improved. Polypropylene (PP) and polyethylene (PE) are the main matrix materials of the diaphragm. However, when approaching the melting point, it will shrink and deform due to melting, resulting in a short circuit between the cathode and anode electrodes, and there is a risk of battery combustion or explosion.

- Daphragm wet coating

It can improve quality and efficiency, and coating can improve battery temperature resistance and safety, and can play a differentiated advantage. The wet diaphragm coating material is mainly alumina coating, and PVDF coating coexists at the same time.

Related articles: Top 10 energy storage lithium battery companies, battery technology, lithium battery recycling