With the development of power electronics technology to this day, it not only involves the conversion and application of electricity, but also involves the conversion and application of chemical energy power sources (such as 12v 100ah lithium ion batteries) and off grid solar batteries.

As far as power electronics technology itself is concerned, it mainly includes two aspects, namely power semiconductor device manufacturing technology and power semiconductor converter technology. The former is the basis of power electronics technology, and the latter is the core of power electronics technology. The two are complementary, interdependent, and mutually reinforcing.

This article will introduce you to the relationship and development history of converter technology and semiconductor power converters.

Main content:

1. Power semiconductor devices

The development of semiconductor converter technology is based on the development of power semiconductor devices. Power semiconductor devices have gradually developed starting from the production of silicon rectifiers (SR) in the United States in 1956 and thyristors (SCR) in 1958.

After more than 40 years of development, device manufacturing technology has continued to improve, and has experienced discrete devices represented by thyristors, such as gate turn-off thyristor (GTO), giant transistors (GTR), power MOSFETs, and insulated gate bipolar transistors; and power integrated devices (PID) represented by IGBT); and power integrated circuits (PIC) represented by intelligent power integrated circuits (SPIC) and high-voltage power integrated circuits (HVIC).

In terms of device structure, it has developed from discrete devices to primary modules that combine discrete devices into power conversion circuits, and then to complex modules that combine power conversion circuits with trigger control circuits, buffer circuits, detection circuits, etc. Power integrated devices are developing more rapidly from single devices to modules, and today modules with intelligent functions (IPM) have been developed.

![]()

Development of representative power semiconductor devices:

|

Development History |

Device Type |

Control Mode |

Structural Features |

|

|

First-generation discrete devices (DD) |

Diodes |

Ordinary, fast-recovery, Schottky type, Others. |

Uncontrolled commutation disconnect, |

Discrete devices, or modules composed of several discrete device chips. |

|

Thyristors |

Ordinary, bidirectional, reverse conduction type, light control type, others. |

Semi-controlled commutation off-current type |

Discrete devices, or simple modules composed of several discrete device chips; or module composed of several discrete device chips and auxiliary circuits. |

|

|

Second generation power integrated device (PID) |

Gate turn-off type (GTO), others. |

Full control, current type control |

Integrated devices, or modules composed of several integrated device chips and auxiliary circuits. |

|

|

Giant transistor (GTR) |

||||

|

Power MOSFET insulated gate bipolar transistor (IGBT), static induction transistor (SIT), others |

Full control, voltage type control |

Integrated devices, or intelligent modules composed of several integrated device chips, auxiliary circuits, and intelligent circuits. |

||

|

Third generation power integrated circuit (PIC) |

Smart power integrated circuit (SPIC), high voltage power integrated circuit (HVIC) |

An intelligent ultra-large area integrated circuit that integrates multi-functional units including power devices. |

||

All of this lays the foundation for the development of high-frequency conversion technology, realizing high-frequency, miniaturization, and lightweight converters, saving energy, materials, and improving efficiency and reliability.

2. Application scope of converter technology

With the development of converter technology, its application scope can be roughly divided into five aspects.

- Rectification: realize AC/DC conversion;

- Inverter from 500w inverter to 3000w inverter: realize DC/AC conversion;

- Frequency conversion: realize AC/AC (AC/DC/AC) conversion;

- Chopping: realize DC/DC (AC/DC/DC) conversion;

- Static solid-state circuit breaker: realize the functions of a contactless switch and circuit breaker, and controls the on-off of electric energy.

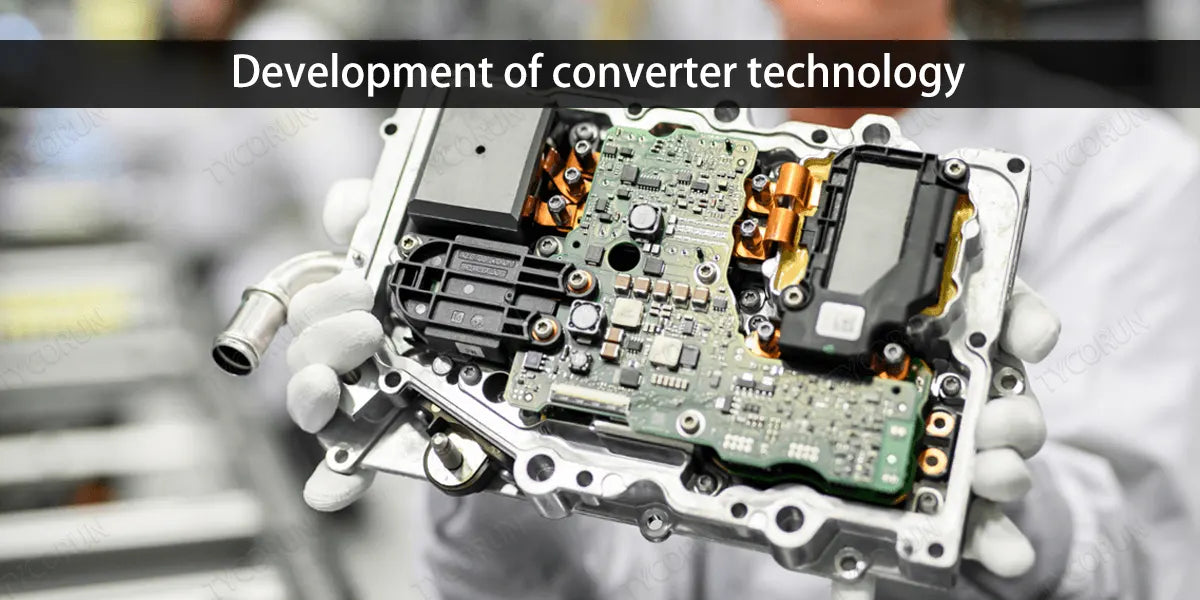

3. Development of converter technology

The development of converter technology has gone through three stages.

(1) First stage

The first stage is based on the development and application of electron tubes and ion tubes (thyratrons, mercury arc rectifiers, high-pressure mercury arc valves). The research work at this stage mainly focuses on the development of rectification, inverter and frequency conversion technologies. The application fields of converter technology are mainly DC drive, DC traction, electrochemistry, electrosmelting, medium frequency, high frequency quenching, heating, high voltage DC transmission, etc.

Since DC drive, DC traction, and electrochemistry and electrosmelting have overwhelming advantages in the application of converter technology, DC drive, traction, and electrification were the three pillars of the converter industry at that time. In fact, from the classification of converter technology, it belongs to rectifier conversion and is a small part of converter technology.

(2) Second stage

The second stage is based on the development and application of silicon rectifiers and thyristors, mainly thyristors. This stage is mainly for applied research on new problems that will arise after silicon rectifiers and thyristors replace electron tubes and ion tubes. For example, the blocking voltage of silicon rectifiers and thyristors is not high, the on-state current is not large, and they can withstand overvoltage, The overcurrent impact capability is not strong, and any abnormal conditions during application may cause permanent damage to the device.

With the continuous improvement of device manufacturing level and the continuous improvement of converter device protection measures, the application technology of silicon rectifiers and thyristors in converter devices has become increasingly mature. During this period, as the manufacturing technology of rectifiers, especially thyristors, continued to improve, the application fields involved in semiconductor inverter technology continued to expand.

For example, the development of fast thyristors has greatly promoted the development of medium-frequency induction heating, smelting, and quenching power supplies (1kHz ~ 8kHz); thyristor low-frequency power supplies, 400Hz medium-frequency power supplies, high-precision voltage-stabilized power supplies and steady-current power supplies that serve national defense construction and high-tech research power supplies were developed one after another.

At this stage, research on chopper technology to achieve DC/DC conversion has been carried out, and it was first used in DC traction speed regulation. The thyristor speed regulation used on bus trolleybuses is an example of DC/DC conversion application.

However, because the thyristor is a semi-controlled device, when it is used in DC/DC conversion, in order to force it to turn off, the main circuit and control circuit are relatively complicated, but its effect of energy saving is significant.

(3) Third stage

The third stage is based on the development and application of fully controllable power semiconductor devices. It is the stage in which semiconductor power converters develop toward high frequency. It is also the stage in which the control method of the converter device changes from phase shift control to time ratio control(TRC).

There are generally three types of TRC, namely pulse width moduration (PWM), pulse frequency modulation (PFM), and hybrid modulation (PWM+PFM). The PWM method has a fixed modulation frequency, that is, the modulation period T is constant (or basically unchanged).

The conversion circuit is adjusted by changing the duty cycle D of the control pulse, which makes the design of the filter circuit relatively simple. Therefore, the commonly used TRC is the PWM.

Since the PWM circuit is a hard-switching circuit, on the one hand, the conversion device in the circuit is subjected to large voltage stress and current stress when working, and at the same time, high dv/dt and di/dt during the conversion process will produce serious electromagnetic interference, causing the electrical problem of electromagnetic compatibility of electronic equipment.

On the other hand, the problem of device turn-on and turn-off loss is becoming increasingly difficult, which seriously restricts the further improvement of the conversion frequency. So soft switching circuits based on the principles of resonance and quasi-resonance, namely zero-voltage switching (ZVS) and zero-current switching (ZCS) circuits, were born.

It is a new type of converter circuit that uses resonance for phase commutation. It realizes the turn-on of the device at zero voltage and the turn-off of the device at zero current, thereby greatly reducing the switching loss of the device. In this way, TRC technology + soft Switching technology allows the conversion frequency to be further increased.

Later, represented by the application of voltage-controlled and hybrid full-control devices such as power MOSFETs and IGBTs, high frequency was truly realized, making the conversion frequency reach 100kHz to 500kHz or even higher, making electrical and electronic equipment more high-frequency and compact. It creates conditions for modernization, high efficiency, energy saving and material saving.

![]()

4. Relationship between semiconductor converting and power supply technology

- Semiconductor power conversion devices used in power supply technology are power semiconductor devices;

- The problems to be solved by power supply technology are still inseparable from power conversion, and its theoretical basis is semiconductor converter technology;

- AC and DC stable power supplies and UPS that are involved in power supply technology are all part of semiconductor power converters. AC/DC, DC/AC, AC/AC, DC/DC conversion technology are also semiconductor converter technology, and they are the problems that have already been solved by semiconductor converting technology;

- The chemical power sources used in power supply technology - LFP battery, and the physical power sources - generators and solar cells belong to different categories;

- The issue of electromagnetic compatibility is a big issue and belongs to the category of radio technology. Power supply technology also uses general electromagnetic compatibility technology in the process of information transmission. It is mainly used to solve the problems that high frequency brings to the power supply itself and other electronic equipment.

Related posts: 21700 battery, battery stores near me, lawn mower battery