Main content:

Inverters play an important role in the electrical system of RVs. Its main function is to convert the direct current provided by the on-board battery pack into alternating current for use in the motor(dc to ac converter 500 watt). In addition, during regenerative braking, the inverter converts alternating current into direct current to charge the battery pack.

Having an efficient and lightweight inverter can extend the range. It can also reduce the size of the battery pack, resulting in cost savings. The inverter has a component called a power module with a semiconductor switchgear that generates alternating current by turning it on and off to change the direction of the current.

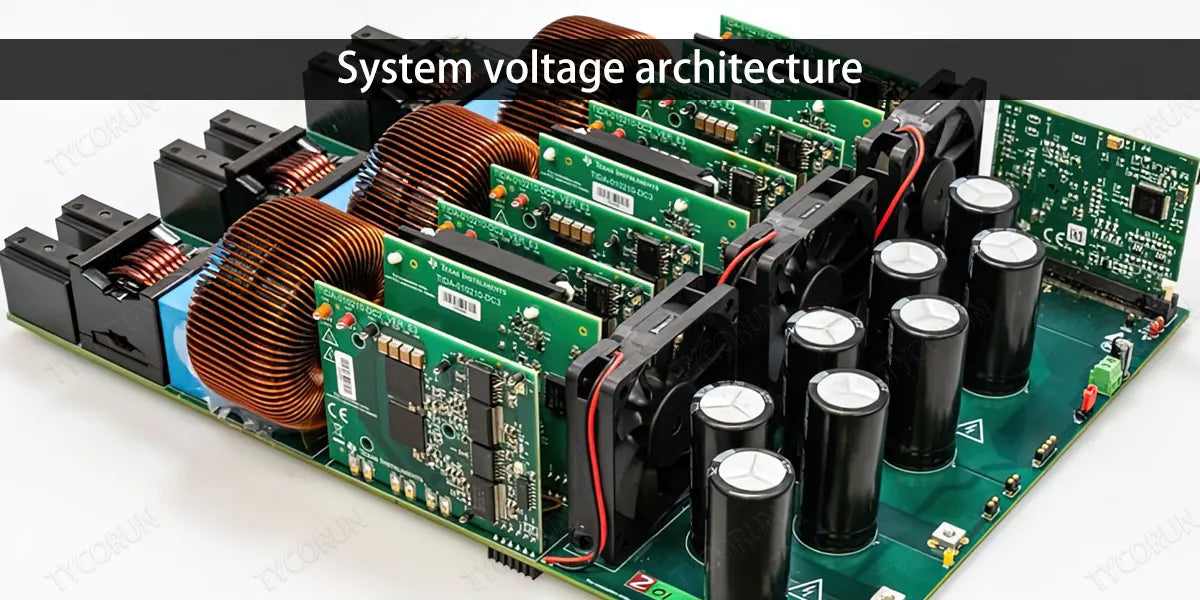

1. System voltage architecture

The choice of switchgear technology depends largely on the voltage architecture. Therefore, it is important to understand what this means and how it will affect the demand for various types of inverters.

● Conventional internal combustion engines

A system that uses 12v battery or occasionally 24V to power in-vehicle circuitry such as electronic controllers, lights, and infotainment systems. In order to improve efficiency and emission control, 48V architecture systems were developed.

● Hybrid Electric

Hybrid electric drives are used, in which an electric motor or generator can assist the combustion engine or supply power directly. Some auxiliary systems such as air conditioning, forced sensing and start-stop functions can be operated with a 48V auxiliary battery pack, which significantly reduces fuel consumption.

In terms of the inverters used, it is expected that there will be a significant difference between the three voltage levels.

In the low-voltage category, silicon (Si) metal-oxide-semiconductor field-effect transistors (MOSFETs) are the most commonly used type of inverter, while insulated-gate bipolar transistor (IGBT) inverters are most commonly used at medium and high voltage levels.

But in the high-voltage category, SiC inverters will be the most commonly used inverters. At present, the share of IGBT inverters in high-voltage inverters is close to 90%, and the remaining 10% is SiC inverters.

However, this will change significantly by 2034, with SiC inverters expected to account for 55% of the market share. The share of IGBT inverters is expected to fall to 38%. GaN inverters are expected to account for 7% of the high-voltage inverter category.

2. What are the types of inverter

Four types of drive inverters are used, depending on semiconductor switching technology. There are types like power inverter 3000w. This section describes how these technologies stack up and how they are being used in the electronics industry.

● Metal-oxide-semiconductor field-effect transistors (MOSFETs)

A MOSFET has three terminals, a source, a drain, and a gate terminal. Higher efficiency in low-voltage applications up to 100V and peak power of 20kW.

This is due to small conduction losses and low voltage drops, which allow it to operate at high frequencies. However, as the system voltage increases, high on-losses make the Si MOSFET inverter less efficient.

● Insulated-gate bipolar transistors (IGBTs)

IGBT is a three-phase silicon-based switching device, but it does not have a source, drain, or gate terminal. Instead, it has an emitter, collector, and gate terminal. The switching device is best suited for powering drive motors from 35 kW to 85 kW.

Compared to Si MOSFETs, IGBTs have a lower switching frequency but are more resistant to electrostatic discharge. IGBTs also have lower conduction losses at higher voltages.

● Gallium nitride (GaN)

GaN is another broad bandgap semiconductor technology that solar inverter company is working on. The intrinsic nature of GaN enables faster switching capability, further improving inverter performance.

In some voltage architectures, GaN is even more efficient than SiC. GaN is still a relatively new technology, and its application in EV inverters is still being studied.

● Silicon carbide (SiC)

High-efficiency inverters can extend the range and performance of electric vehicles without significantly increasing their weight or cost. While IGBT has good efficiency, it also has drawbacks due to the silicon material on which it is based.

To solve this problem, the automotive industry is increasingly turning to silicon carbide, which provides better characteristics for PV inverter.

Compared to SI IGBTs, SiC has higher electric field breakdown capability, better thermal conductivity, higher temperature operation, and higher switching frequency, resulting in lower switching and conduction losses.

SiC's better thermal conductivity allows inverters to dissipate heat faster and more efficiently. This allows for the use of smaller and cost-effective cooling solutions. However, SiC inverters are still relatively expensive.

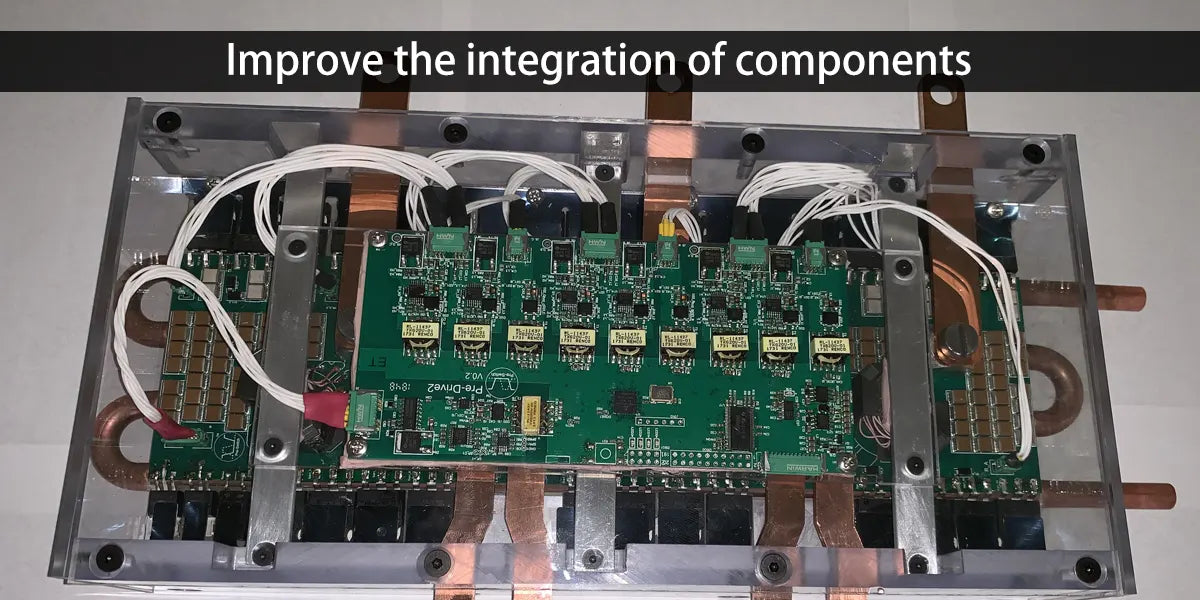

3. Improve the integration of components

One way to improve the efficiency of cars is to increase the integration of components. It can improve space utilization, reduce system losses and provide better thermal performance. As of 2023, the integration of electric motors and inverters is the most widely used configuration.

In an electrified light vehicle, about 49% of the inverters are configured in this configuration. This is followed by inverter and DC-DC configurations with a 31% market share. Inverters and DC-DC are the most commonly used configurations in full hybrid hybrids.

Motor + inverter is expected to remain the preferred configuration for the foreseeable future. In fact, by 2034, the share of such a configuration will increase to 61%.

On the other hand, the share of inverter + DC-DC integrated configuration will decline, and the proportion will fall to 19% during the same period.

Currently, inverters installed as stand-alone units account for 19% of the total installed inverter in electric vehicles. This share is also expected to remain at 18% by 2034.

4. Global demand for inverters

Total global demand for inverters will grow from 43.99 million units in 2023 to 120 million units in 2034, at a CAGR of 9.55%. Currently, IGBT inverters are the most widely used inverter type in all types of electric vehicles worldwide, followed by Si MOSFETs.

However, with the increasing demand for BEVs and the shift to 800V architectures, the demand for SiC inverters is likely to increase. By 2034, the market share of SiC and IGBT inverters will reach 44% and 45%, respectively, almost evenly divided.

Demand for inverters in major automotive regions is directly related to the number of alternative-powered vehicles produced in the region. China leads the way in overall inverter demand and will continue to do so.

5. Conclusion

Demand will be strong as the need for greater efficiency and a wider range continues. The widespread adoption of inverters will lead to many companies working together to secure supply in the market.

Different types of inverters are available from Tycorun, please check 3000 watt car inverter, 2000 watt inverter, 1000 watt inverter, 500 watt inverter

Related articles: distributed pv system, top 10 PV inverter companies, solar microinverter