Motor inverter is an electric energy conversion device, its role is to convert direct current energy into AC electrical energy to control the speed and torque of the AC motor. This article will focus on four aspects to introduce motor inverter: the role of motor inverter, the difference between electric motor inverter and motor controller, the cause of motor inverter failure and how to deal with failure.

Main content:

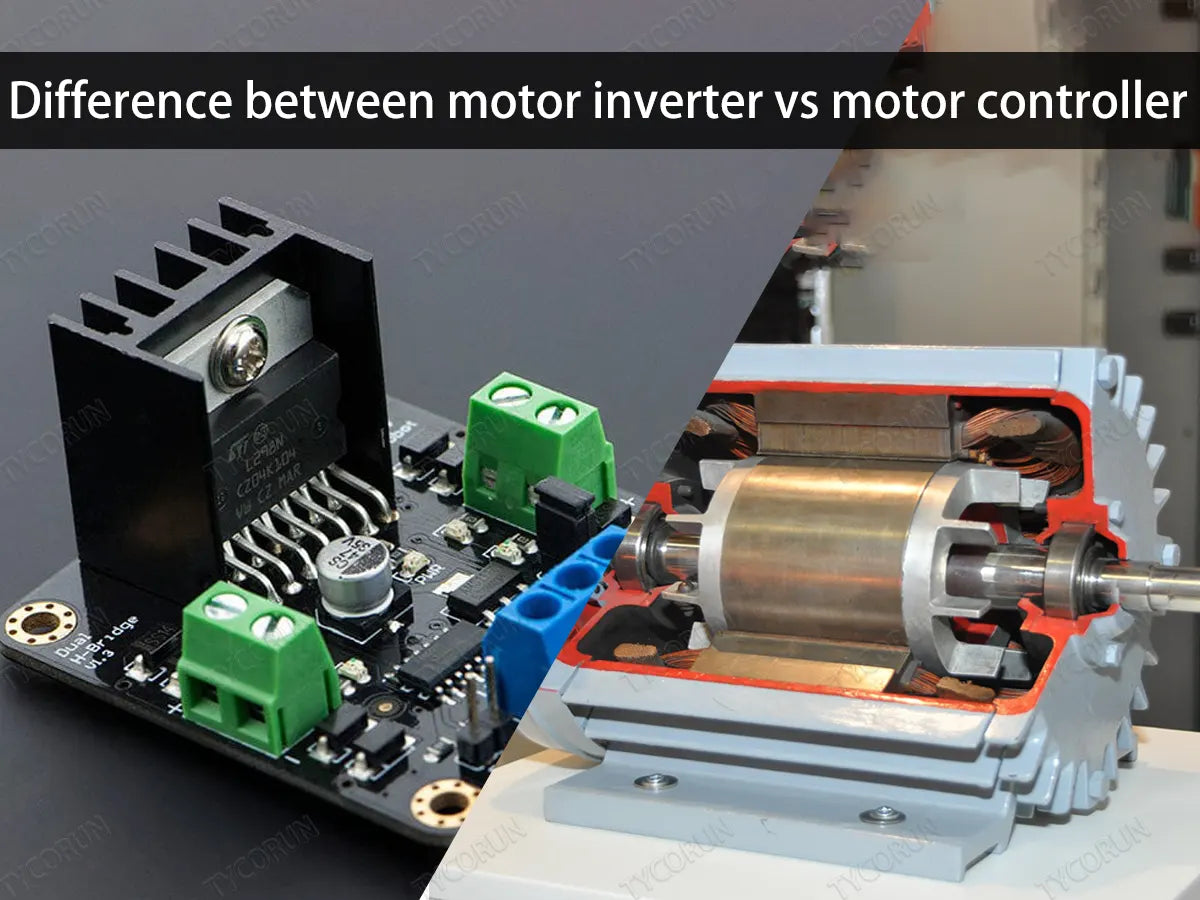

1. The main function of motor inverter

Electric motor inverter plays an important role in the motor drive system, the following are several main functions of motor inverter:

- Drive motor control:

motor inverter can adjust the output frequency and voltage to achieve accurate control of AC motor. By changing the output frequency, the variable speed control of the motor can be realized to meet the speed requirements under different working conditions. At the same time, by adjusting the output voltage, the torque and power output of the motor can be adjusted to achieve flexible control under various load conditions.

- Energy saving:

The motor inverter can dynamically adjust the working conditions of the motor according to the load demand to achieve energy saving control. By adjusting the output frequency and voltage, the motor can work at the best efficiency point under different loads, thereby reducing energy consumption and loss and improving the energy utilization rate of the whole system.

- Soft start and smooth control:

motor inverter can provide soft start and smooth control functions when starting and stopping. Compared with the traditional direct start method, gradually increasing the output inverter voltage and frequency through the electric motor inverter can reduce the current shock and mechanical shock at start, extend the life of the motor and mechanical equipment, while providing a smoother operation.

- Feedback control and protection function:

motor inverter is usually equipped with a variety of feedback sensor interfaces, such as encoders, sensors, etc., for real-time monitoring of the motor's operating status and parameters. By acquiring and processing the feedback signal, the closed-loop control can be realized and the control precision and stability of the motor can be improved.

In addition, the motor inverter also provides a variety of inverter protection functions, such as over-current protection, overload protection, over-temperature protection, etc., to ensure the safe operation of the motor and electric motor inverter.

The motor inverter has multiple functions such as conversion, control, energy saving and protection in the motor drive system, which can improve the performance and efficiency of the motor system, and meet the power needs of different working conditions.

2. Difference between motor inverter vs motor controller

Motor inverter and motor controller are two different components in a motor drive system that differ in function and application.

- Function:

motor inverter is mainly responsible for converting direct current energy to AC electric energy, and can adjust the output frequency and voltage to control the speed and torque of the AC motor. motor inverter achieves precise control of the motor by controlling the output voltage and frequency, and provides soft start, smooth control, energy saving and other functions.

The motor controller is a more general term, which includes the realization of the control algorithm and logic of the motor, which may include speed closed-loop control, position control, torque control and other control methods. The motor controller is responsible for calculating the appropriate motor control signal based on the input signal and feedback signal to achieve the specific motion control requirements.

- Application range:

motor inverter is usually used for AC motor drive system, can be equipped with various types of AC machines, such as induction motor, permanent magnet synchronous motor, etc. motor inverter is commonly used in industrial automation, transportation, power engineering and other fields.

The motor controller has a wider range of applications and can be used to drive different types of motors, such as DC motors, stepper motors, etc., and can adapt to various application needs, such as robots, automation equipment, electric vehicles, etc.

- Hardware and software:

motor inverter is usually an electronic hardware device, composed of power electronics, control circuits and interface circuits. Its design and manufacture involve electronic circuits, power transmission and control technology. The motor controller is more involved in software algorithm and programming, need to have the relevant control algorithm design and programming capabilities. The motor controller can be implemented by microcontroller, digital signal processor (DSP) or special control chip.

Although motor inverter and motor controller have certain differences in function and application, they can also be used in combination in some cases. For example, the motor inverter can be used in conjunction with the motor controller to provide power conversion and control functions through the motor inverter, while the motor controller provides advanced motion control algorithms and logic to enable more complex motor drive systems.

3. Motor inverter fault causes and treatment

Failure of the motor inverter may be caused by a variety of reasons, the following are some common causes of failure and their treatment:

① Overload or short circuit: An overload or short circuit may cause the protection of the electric motor inverter to trigger. Treatment includes checking that the circuit connections are correct, ensuring that the motor load is within the rated capacity of the electric motor inverter, and repairing or replacing the faulty circuit.

② Excessive temperature: Motor inverter operating in a high temperature environment may result in overheating failure. Treatment includes ensuring that the electric motor inverter dissipates heat well and cleaning the radiator or fan in a timely manner to keep the motor inverter within the normal operating temperature range.

③ Abnormal input voltage: Too high or too low input voltage may cause motor inverter's protection to trigger or malfunction.Treatment includes checking whether the power supply voltage is in accordance with the rated voltage range of the electric motor inverter, ensuring that the power supply is stable, and taking appropriate voltage regulation measures.

④ Abnormal control signals: If the electric motor inverter receives incorrect or interfering control signals, it may lead to abnormal operation or protection triggering. Treatment includes checking the control signal line and transmission equipment to ensure that the signal transmission is correct and stable.

⑤ Power supply failure: Failure of the power supply used by the electric motor inverter (e.g. unstable power supply voltage, power grid failure, etc.) may cause the electric motor inverter to fail to work normally. The treatment method includes checking the power supply system, repairing or replacing the faulty power supply.

⑥ Other malfunctions: Failure of electric motor inverter components, circuit board burnout, capacitor failure, etc. may cause electric motor inverter failure. Treatment includes checking the internal components of the electric motor inverter and making necessary repairs, replacements, or testing.

The following steps are recommended to be followed when dealing with electric motor inverter faults:

- According to the motor inverter's fault indicator or fault code, initially determine the type of fault.

- Check whether the power supply and circuit connection are normal, make sure the electrical connection is reliable.

- Check whether the temperature and voltage are within the normal range and take necessary adjustment measures.

- Check the control signal and transmission equipment to ensure that the signal transmission is correct.

- If the fault still cannot be solved, it is recommended to contact the motor inverter supplier or senior technician for checking and repairing.

We have also written about PV inverter, inverter for van, camping inverter, RV inverter Installation, power inverter for truck, if you are interested. More articles about inverters can be found by clicking on PV inverter, RV inverter, power inverter for truck.

Related posts: global top 10 best solar inverter brands, top 10 solar inverter best brands in USA, top 10 solar inverters in Australia