Main content:

How often does the inverter, which is one of the core components of a PV system, need to be replaced? It is generally believed that the inverter is limited by internal electronic components (IGBT, capacitor, inductor, etc.)

And the service life is generally not more than 10 years, and the inverter should be replaced at least once throughout the life cycle of the photovoltaic power station.

1. Failure factors that lead to shortened lifespans

The service life and use environment of the inverter, the quality of components, etc., have a great relationship. Components include structural parts, circuit boards, inverter switch, capacitors, LCD displays, fans, and other components.

The life of the inverter is determined by the shortest life components, usually IGBTs, capacitors, inductors, etc., and the service life is generally not more than 10 years.

Such as electrolytic capacitors, which are one of the most vulnerable devices for inverters to fail. The electrolyte in the electrolytic capacitor gradually evaporates and dries out, resulting in an increase in the equivalent series impedance of the electrolytic capacitor.

At the same current, higher resistance causes the capacitor to heat up, which increases electrolyte evaporation and ultimately leads to device failure. Another example is thermal grease, which has a life span of about 10 years.

If the thermal grease fails, it will not be able to conduct the heat generated by the electronic components in time. Components can age and deteriorate quickly. Some components with a life of less than 25 years also include LCD displays, plastic connectors, cables, terminal blocks, etc.

2. The usage environment of the runtime

If the components are the internal factor, then the use environment is the external factor that affects the life of the inverter 3000w. Usually, the inverter must go through outdoor demonstration tests, including climate resistance, acid and alkali resistance, salt spray, waterproof, high and low temperature cycling and other performance tests.

The life of the inverter is greatly affected by the installation location of the equipment, and the TTF (time to failure) of the outdoor installation is shorter.

Because the temperature inside the inverter is the most important factor affecting the life of the inverter (component).

- Direct sunlight exposure will increase the operating temperature.

- Confined space installation can affect heat dissipation.

- Surface dust accumulation can also affect heat dissipation.

- Exposure to the sun, wind and rain will affect the life of the shell, connectors, etc.

Therefore, when installing an inverter, it is necessary to consider providing a suitable working environment for it. Don't think that the inverter was originally designed for outdoor applications, even though the housing is metal.

If it is installed outdoors, it is best to install it under the eaves of the back-to-back side or under the photovoltaic modules, or to install a sunshade and rain shelter.

Try to stay away from high-temperature areas such as boilers, oil-fired hot air fans, heating ducts, and air conditioning exhaust outlets. Try to provide measures to prevent sand, dust, and fallen leaves.

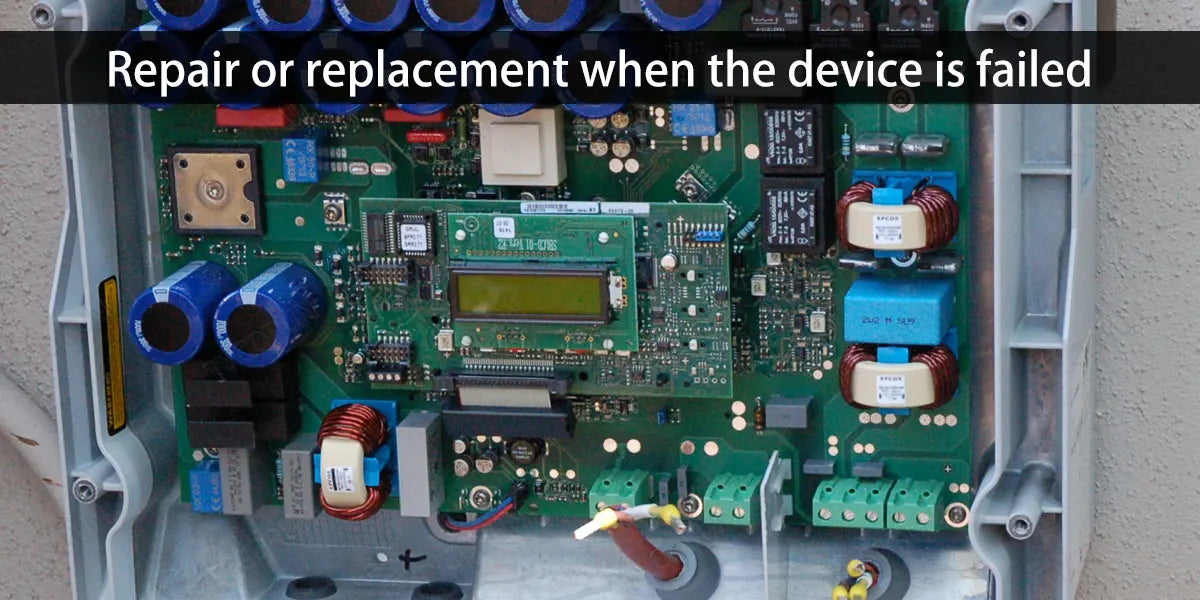

3. Repair or replacement when the device is failed

Failure of inverter components may affect power generation, stop working, or not affect power generation. The failure of capacitors, silicone grease, etc. is also a gradual process, which will gradually reduce the efficiency of the inverter. Therefore, it is recommended to maintain the inverter first to delay the aging of the inverter components.

When the reverse fails or you degrade inefficiencies that you think are unacceptable, is it a repair or replacement?

As a power electronic device, repairs are possible at any time, but they need to be repaired or replaced in terms of economy. Some may be simple failures, such as a faulty display or a rusted casing, and do not affect the power generation.

Some of them may affect power generation, such as opening the power inverter 2000 housing and finding that the wiring is loose and the silicone grease is gone (the same as the computer's thermal grease). These may be things that can be done by yourself, or things that ordinary electrical maintenance workers can do, so you might as well try it first.

For some complex faults, professional maintenance personnel may be required to perform repairs. It may be a replacement of parts, or it may involve replacing a complete machine. At present, string inverters generally adopt the maintenance method of replacing the whole machine, and it is not easy to find suitable components.

For centralized inverter failures, module maintenance is generally adopted. The overall value of the centralized inverter is high, and the replacement cost is high. Usually the whole machine is divided into several modules, and the faulty module is detected first, and then the faulty module is replaced.

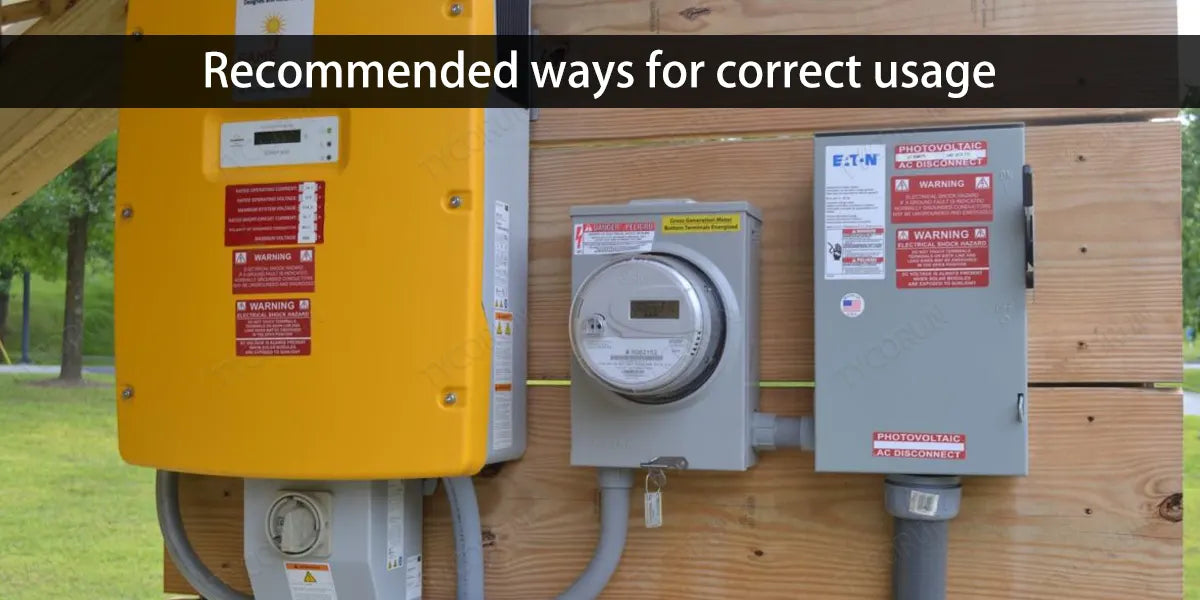

4. Recommended ways for correct usage

The connection and installation of the equipment shall be carried out in strict accordance with the requirements of the inverter operation and maintenance manual.

At the time of installation, it should be carefully checked:

- The wire diameter meets the requirements.

- Parts and terminals are loose during transportation.

- The insulated place should be well insulated.

The grounding of the distributed pv system is in accordance with. It should be operated and used in strict accordance with the provisions of the inverter operation and maintenance manual. Especially:

- Pay attention to whether the input voltage is normal before turning on the machine.

- When operating, pay attention to whether the sequence of switching on and off is correct.

- Whether the indication of each meter head and indicator light is normal.

- The inverter generally has automatic protection against open circuit, overcurrent, overvoltage, overheating and other items.

Therefore, when these phenomena occur, there is no need for manual downtime. Automatic protection points are usually set at the factory and do not need to be adjusted.

5. Conclusion

When the room temperature exceeds 30°C, heat dissipation and cooling measures should be taken. In order to prevent equipment failure and prolong the service life of the equipment.

As an important part of the solar power generation system, the inverter has a failure in the process of operation, and this article discusses how we should maintain and overhaul it. What to do as a non-professional. Today, the use and maintenance of inverters are introduced.

Tycorun 12V inverters guarantee reliable pure sine wave output with a lower price than other competitors, please check power inverter 3000w, 2000w pure sine wave inverter, power inverter 1000w, 500 w inverter price

Related articles: Top 5 inverter battery companies, home solar inverter, top 10 PV inverter companies