Main content:

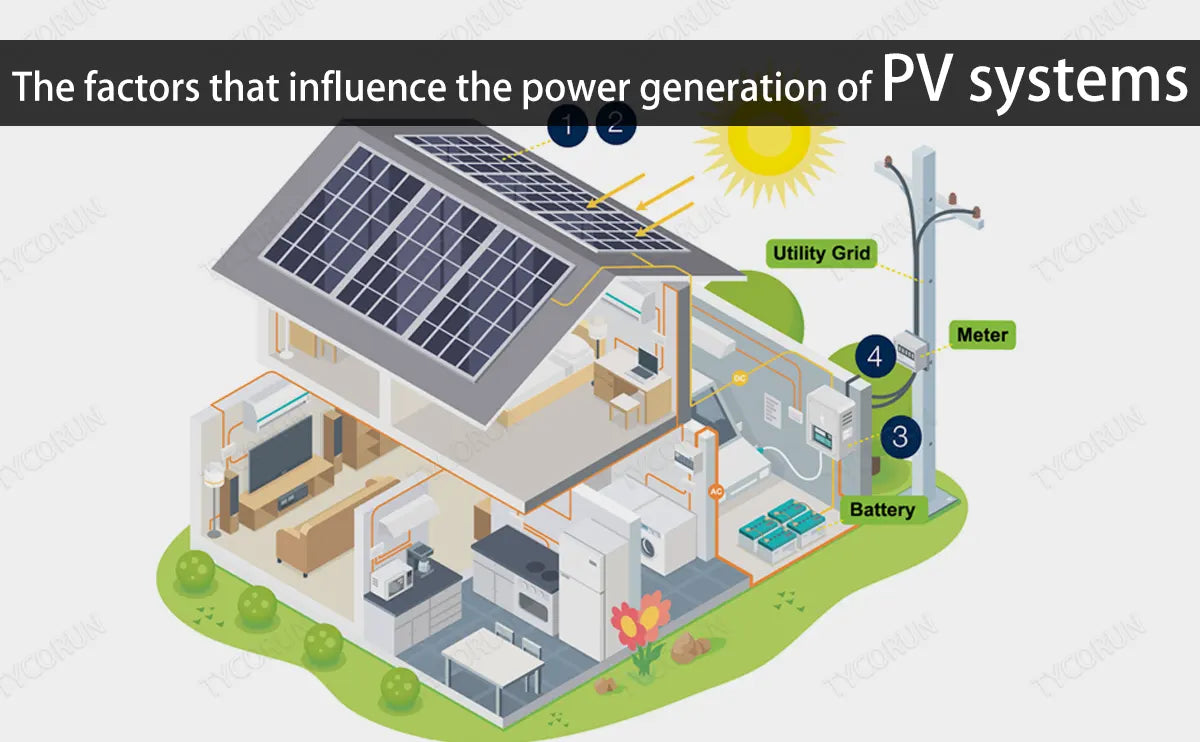

For photovoltaic power generation systems, each additional kilowatt-hour of electricity generates more revenue. The power generation of a photovoltaic power station will be affected by many factors.

Such as: the quality of photovoltaic modules, inverters, cables, module installation orientation, tilt, dust shading, photovoltaic modules and inverter ratio system scheme, grid quality, etc. This article analyses the various factors that affect the amount of electricity generated.

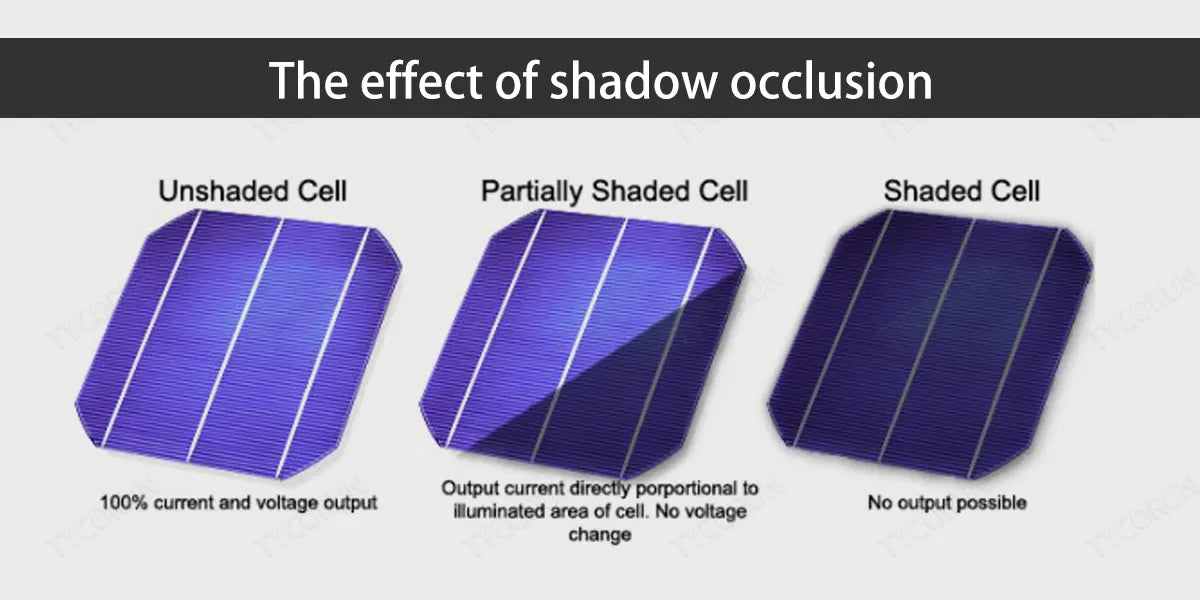

1. The effect of shadow occlusion

Among the many factors that affect the power generation of photovoltaic power generation system, shadow occlusion is one of the most common. Common occlusions mainly include utility poles, trees, guardrails, dust, and front and rear occlusions of components.

In the construction process of many power plants, it is often impossible to completely avoid shadows, and many people will feel that the small shadow area will not have a great impact.

In fact, if some components or one component is blocked, the entire component string will be affected. This is called a series circuit. In a string of components, each piece of current is the same, and the maximum current is determined by the smallest component.

Therefore, as long as one component is blocked, the output power of the entire string will be affected. In severe cases, it will also lead to the hot spot effect of the module, reducing the power generation efficiency and service life of the module.

It can even lead to the partial burning of components, which brings certain safety risks. Therefore, it is not only necessary to avoid shadows when designing the power station, but also to pay attention to later operation and maintenance, and regularly clean the components.

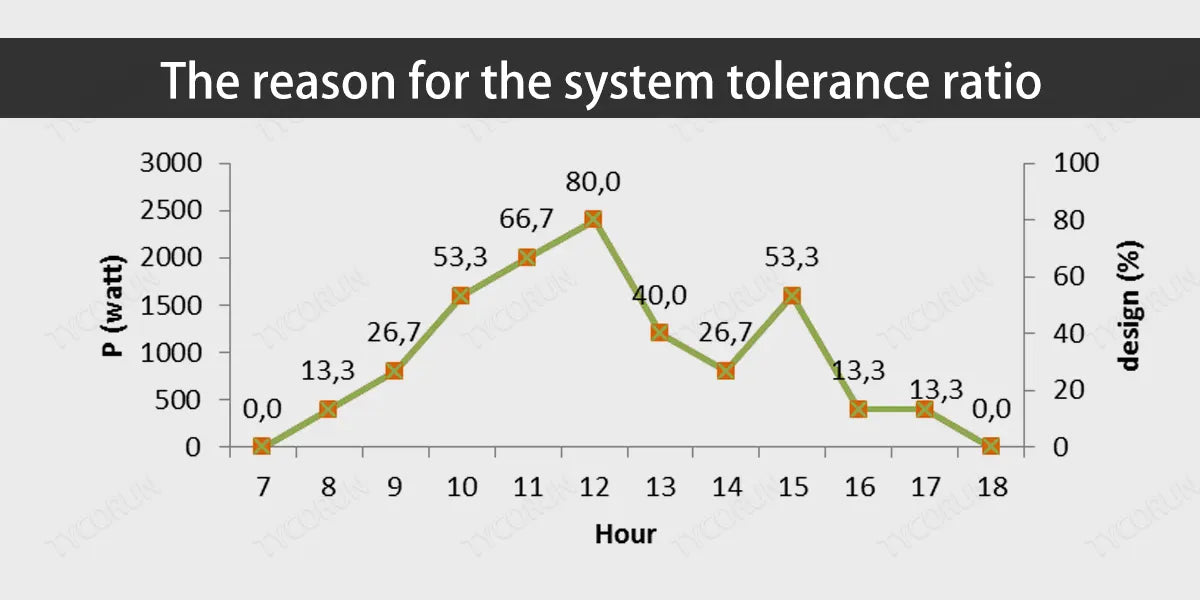

2. The reason for the system tolerance ratio

Capacity to Ratio refers to the ratio of the installed capacity of the PV system to the rated capacity of the 2000w inverter. If the PV system is designed according to a capacity ratio of 1:1, the inverter capacity will be wasted when the output power of the PV module does not reach the nominal power.

At present, over-configuration design is often used to improve the overall utilization rate of photovoltaic systems, reduce the power cost of the system, and increase the revenue of power stations. However, this does not mean that the capacity ratio can be extended indefinitely to save inverter costs.

Because the cost of inverters accounts for only about 5% of the entire PV system, it is not cost-effective to globalize too much. It will also cause the inverter to operate at a limited capacity, resulting in a loss of power generation. Therefore, a reasonable design of the system capacity ratio is conducive to improving the economy of the photovoltaic power generation system.

In different types of resource areas, due to the different conditions of solar energy resources, regional temperature and other characteristics, it is necessary to calculate according to the specific local conditions. The following are the recommended capacity ratios for different areas.

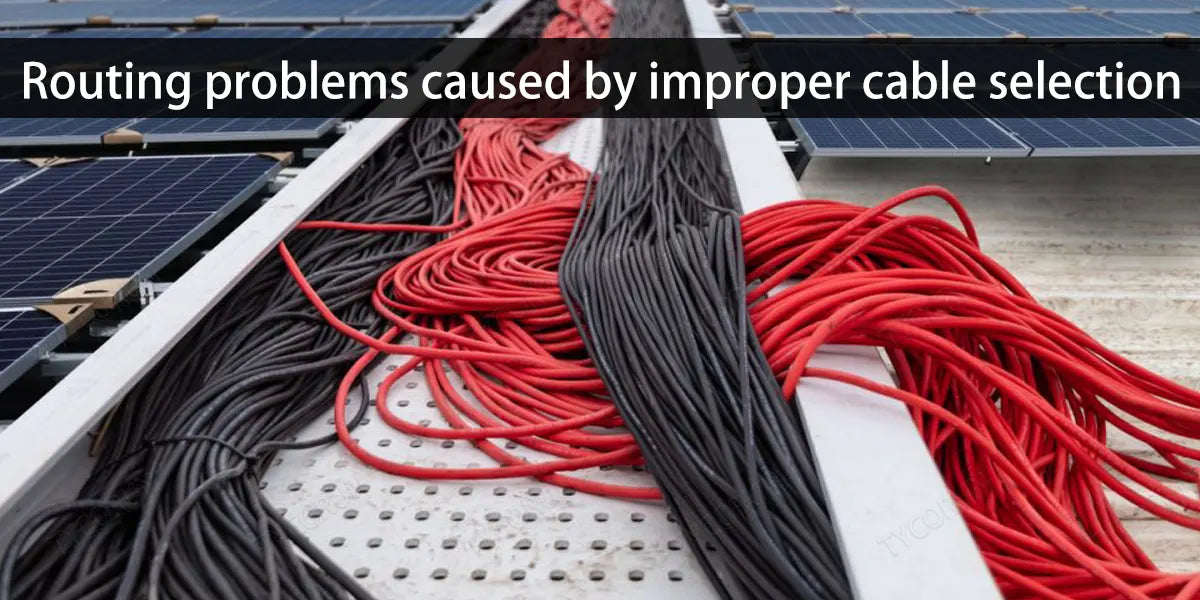

3. Routing problems caused by improper cable selection

If the inverter is compared to the brain of the photovoltaic power station, the cable is the nervous system of the photovoltaic system, connecting photovoltaic modules, inverters, combiner boxes, grid-connected cabinets and other equipment into a whole. Therefore, the right cable selection is crucial for the entire photovoltaic system.

When designing and selecting cables, it is necessary to choose the right wire diameter, especially for large-scale photovoltaic power stations, which cover a large area and have long lines. If the diameter of the AC cable is too thin, it will cause the cable to be overloaded and heated, which will not only affect power generation, but also have potential safety hazards such as short circuits and fire.

Another point to note is that the cross-sectional area of aluminum cables is much larger than that of copper cables for the same current-carrying cable, so it is necessary to consider whether the AC end of the inverter can be connected. The AC output side of the inverter is designed according to the copper wire standard, and it is recommended to use copper core cables.

However, the use of aluminum core cables will save a certain investment cost compared to copper core cables, so many installers will use aluminum core cables. However, it is necessary to use copper and aluminum wiring transition terminals that meet the requirements of the standard.

Because copper-aluminum joints are prone to electrochemical corrosion, the contact between copper and aluminum is poor, and resistance increases, which affects the efficiency of the entire photovoltaic system. Long-term operation will cause the temperature of the joint part to rise, accelerate corrosion, and even burn out.

- Corrosion of copper and aluminum joints

Cable selection has a direct impact on photovoltaic power generation. Choosing the right cable type, specification, and photovoltaic cable with good load capacity, weather resistance and durability can minimize power loss, improve power generation efficiency, and ensure the normal operation of photovoltaic power plants and maximize power generation.

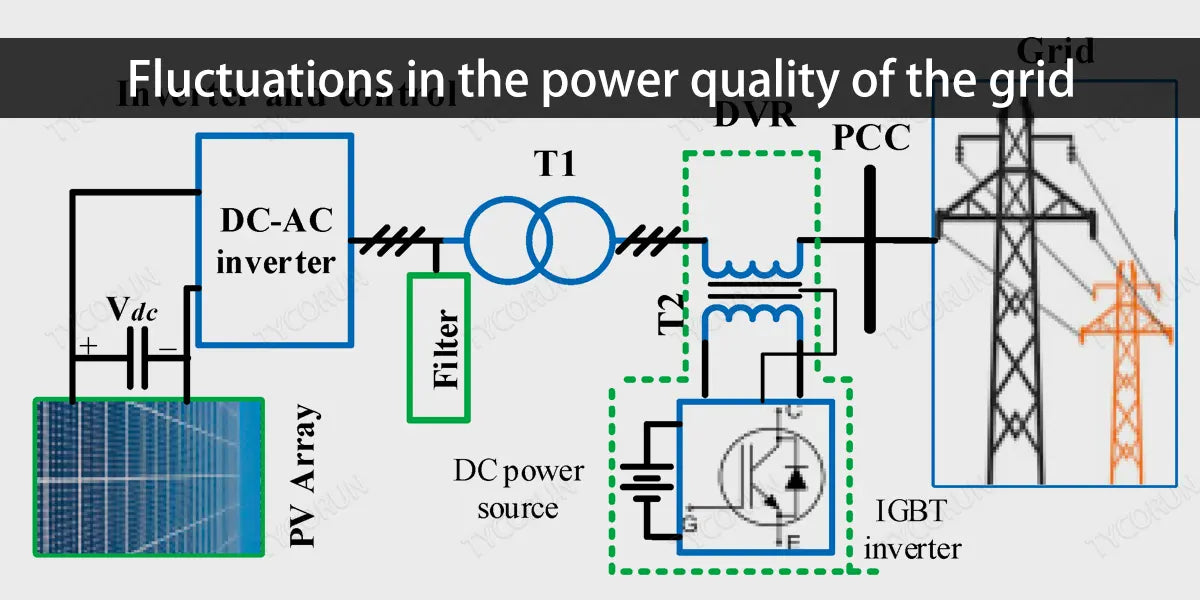

4. Fluctuations in the power quality of the grid

The power quality of the grid includes:

- Voltage deviation

- Current deviation

- Frequency skew

- Voltage fluctuations or flashing

- Three-phase imbalance

- Temporary or transient overvoltages

- Waveform distortion

- Voltage sag

● The grid voltage is out of range

The grid voltage and frequency are not constant and will change with the load and power flow, while the inverter output voltage follows the grid voltage. However, after the grid voltage and frequency fluctuation exceed a certain range, the 3000w inverter will stop working.

● Voltage fluctuations, flicker and harmonics

In some factories, the power changes between start-up and shutdown are very dramatic, accompanied by a large number of harmonics. The presence of harmonics and unbalanced negative sequence components in the grid will cause power fluctuations in the output of the PV system.

And the higher the voltage distortion rate of the grid, the smaller the active output power of the photovoltaic system. It will also output current distortion, and the higher the grid voltage distortion rate, the greater the output current THD of the photovoltaic system.

When the grid voltage fluctuates violently, the inverter has limited adjustment capacity, which may cause the PV inverter to restart frequently. In severe cases, the power device in the inverter may be overpressurized, and the electrolytic capacitor will burst overcurrent.

5. Conclusion

From the above points, the power generation of photovoltaic power stations not only depends on the power generation performance of the photovoltaic power station itself, but also closely related to the later operation and maintenance. Proper operation and maintenance can not only increase power generation, but also increase the service life of equipment and power plants.

Related articles: photovoltaic power station, top 10 solar inverters, high efficiency solar panels