Main content:

1. Definition of cylindrical lithium battery

Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical cylindrical battery includes: casing, cap, cathode, anode, separator, electrolyte, PTC element, gasket, safety valve, etc. Generally, the battery shell is the anode of the battery, the cap is the cathode of the battery, and the battery shell is made of nickel-plated steel plate.

2. The development history of cylindrical lithium battery

Since Tesla's battery day in September 2020 proposed 4680 large cylindrical cells, large cylindrical cells have once again become the focus of the battery industry in the market. In addition to Tesla, China's leading cell factories have also begun to invest in the mass industrialization of large cylindrical cells.

According to the data shown by Tesla, the 4680 large cylindrical lithium battery will increase the energy by 5 times on the basis of the 21700 cylindrical cells, increase the mileage by 16%, and reduce the cost by 14%. Its technical temptation is very significant. However, during the period of rapid development of China's new energy vehicles in the past, first-line brands including CATL and BYD all focused on the technical route of square cells. At present, the industrialization of power batteries is basically based on square batteries, and even Tesla has purchased square batteries with a capacity of about 161Ah in China for use in one of its models.

From a technical perspective, both technical routes have their own value and advantages. In a complex battery system, although batteries account for the highest cost, in terms of safety and cost performance, we cannot only focus on one dimension of batteries. For example, Tesla has industrialized and applied the cylinder 18650 and 21700 to electric vehicles with energy exceeding 70KWH through advanced management system design. In fact, it is using advanced management to optimize the performance of the battery system.

3. Relative advantages of cylindrical lithium battery

● Advantages of small capacity flexibility

Due to size and process limitations of cylindrical cells, the capacity of a single cell is usually small. For example, 18650 ternary battery 3.5Ah, 32700 iron-lithium battery 6Ah, 33140 iron-lithium battery 15Ah, 34190 iron-lithium battery 20Ah, etc. Aside from electric vehicles and large-scale energy storage markets, in other fields, such as AGV, portable energy storage, and home energy storage, the capacity of single-module batteries is usually not very large. In practical applications, the large-capacity square cells positioned for automobiles and large-scale energy storage do not necessarily exactly match the market demand, including size and capacity.

The small-capacity cylindrical lithium battery can be connected in parallel to meet the battery module capacity needs of certain market demands. For example, the two types of lithium batteries 24V60Ah and 48V30Ah used in AGV cars are relatively common needs. Three types of cylinders, 32700, 33140 and 34190, can be combined in parallel to form the required 60Ah or 30Ah modules. At the same time, there are more flexible operation possibilities in the space structure to meet the design requirements of different models.

● Cost advantage

In the production and manufacture of all lithium-ion batteries in lithium battery companies in the world, the process standardization of cylindrical lithium battery is the highest, and it is also the earliest commercialized battery. The assembly efficiency is significantly higher than that of square batteries and pouch batteries. The winding process of cylindrical batteries has reached the level of 200PPM with the gradual improvement of automation. Even though the efficiency of large cylindrical lithium batteries is slightly lower than that of traditional 18650/21700 cylindrical cells, it is much higher than the efficiency of stacking or winding processes of square cells and pouch cells (usually around 10PPM).

The reason for the small capacity of the cylindrical lithium battery is that the strip-shaped continuous pole piece after coating is cut into strip-shaped small pole pieces, and the miniaturization of the pole piece can improve the utilization rate of the entire pole piece material. Usually under the same screening criteria and automation level, the material utilization rate of cylindrical cells is 3-5% higher than that of square cells.

● The heat dissipation effect is obvious

Lithium-ion battery fires are all caused by thermal runaway, and the spread of thermal runaway is also the main concern of battery system safety performance. Cylindrical structure is the most likely solution to thermal runaway, while square and pouch structures are basically unsolvable. The low capacity of a single cell causes thermal runaway to release less energy, which is different from high-energy, large-capacity square cells or pouch cells. At the same time, with the gradual improvement of material safety, the heat release caused by thermal runaway is reduced, which significantly increases the safety of the battery system.

The curved surface structure of the cylindrical lithium battery limits the heat transfer process between the cells to a certain extent, and has a certain positive effect on the spread of thermal runaway. However, square batteries and pouch batteries are basically unsolvable in this regard. Furthermore, with the promotion of the full-tab process, the heat transfer of cylindrical cells is more on the upper and lower end caps of the cells, and the heat transfer on the curved surface will also be reduced.

The above is some analysis and thinking based on different application scenarios of lithium batteries with different structures. Although the focus is on analyzing the advantages of cylindrical lithium battery, it is undeniable that cylindrical cells have shortcomings in certain application fields. At the same time, it is also necessary to objectively understand the own advantages of square cells and pouch cells.

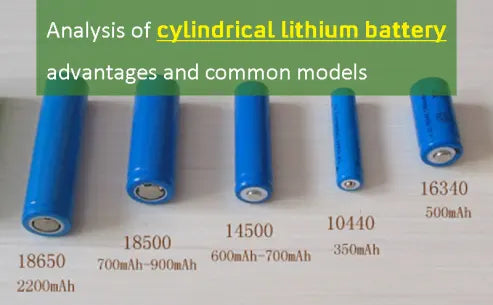

4. Common cylindrical lithium battery models

With the development of lithium battery technology, there are more and more types of cylindrical lithium battery. Cylindrical lithium battery are divided into lithium cobalt oxide, lithium manganese oxide, and ternary materials. The three material systems have different advantages. Let's take a look at the models and specifications of cylindrical lithium battery. Cylindrical lithium battery is usually represented by five digits. Counting from the left, the first and second digits refer to the diameter of the battery, the third and fourth digits refer to the height of the battery, and the fifth digit refers to the circle. There are many types of cylindrical lithium battery, the more common ones are 10400, 14500, 16340, 18650, 21700, 26650, 32650 and so on.

● 10440 battery

The 10440 battery is a cylindrical lithium battery with a diameter of 10mm and a height of 44mm. It is the same size as what we often call the 7th battery. This battery capacity is generally small, only a few hundred mAh, and is mainly used in mini electronic products. Such as flashlights, mini stereos, megaphones, etc.

● 14500 battery

The 14500 battery is a cylindrical lithium battery with a diameter of 14mm and a height of 50mm. This is also the size of what we have always called the AA battery. This kind of battery is generally 3.7V or 3.2V. The nominal capacity is relatively small, a little larger than the 10440 battery, generally 1600mAh, and the discharge performance is superior. The most important application field is consumer electronics, such as wireless audio, electric toys, digital cameras, etc.

● 16340 battery

The 16340 battery is a cylindrical lithium battery with a diameter of 16mm and a height of 34mm. Due to its shorter height and relatively small capacity, this kind of battery often appears in glare flashlights, LED flashlights, headlights, laser lights, lighting fixtures, etc.

● 18650 battery

The 18650 battery is a lithium-ion battery with a diameter of 18mm and a height of 65mm. Its biggest feature is that it has a very high energy density, almost reaching 170 Wh/kg, so this battery is a battery with better cost performance. Most of the 18650 battery store we often see are 18650 batteries, because it is a relatively mature lithium-ion battery, and the system quality is stable in all aspects. It is widely used in occasions with a battery capacity of about 10 kWh, such as mobile phones, notebook computers and other small electrical appliances.

● 21700 battery

The 21700 battery is a cylindrical lithium battery with a diameter of 21mm and a height of 70mm. Because of its larger volume and greater space utilization, the energy density of the battery cell and the system can be improved, and its volumetric energy density is much higher than that of the 18650 battery. Widely used in digital, electric vehicles, balance cars, solar energy lithium-ion battery street lights, LED lights, power tools, etc.

● 26650 battery

The 26650 battery is a cylindrical lithium battery with a diameter of 26mm and a height of 65mm, with a nominal voltage of 3.2V and a nominal capacity of 3200mAh. This kind of cylindrical lithium battery has the characteristics of excellent capacity and high consistency, and has gradually become a trend to replace 18650 batteries. Many products in power lithium batteries will also gradually favor it.

Related articles: 12v battery, 4680 battery vs 18650