main content:

- 1 Create a forest of firewood

- 2 Biogas has become the protagonist of rural energy

- 3 Urban waste recycling

- 4 The right and wrong of ethanol energy

1 Create a forest of firewood

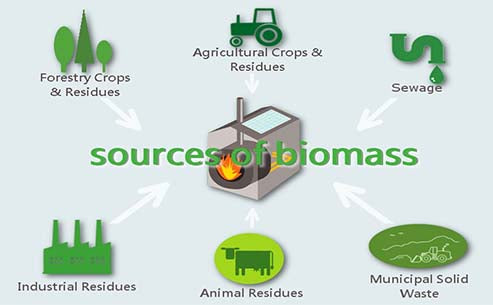

Plants, animals, and microorganisms are all biomass. The energy contained in biomass is called biomass energy. However, only plants are the creators of biomass energy. Under the action of sunlight, plants convert water and carbon dioxide into organic matter through photosynthesis, that is, biomass; convert solar energy into chemical energy and store it in biomass to become biomass energy and release oxygen at the same time. Of course, animals are also biomass and contain energy, but the basis of their food chain is also plants. Even carnivores cannot do without plants. Without plant-eating animals, carnivores no longer exist. When biomass is decomposed, the chemical energy stored in it will be released (such as burning heat), or converted into other forms of chemical energy (such as generating biogas). It can be seen that the photosynthesis of plants will fix the carbon and turn it into organic matter. Plants on the earth fix about 200 billion tons of carbon each year through photosynthesis, and the energy contained is equivalent to 72 billion tons of oil, which is equivalent to 8 times the current annual energy consumption of the world. Such a huge biological resource has a wide variety of species, including animals and plants on land and sea, human and animal excrement, organic waste from industry and urban life, and organic matter in sewage. Although biomass resources are very abundant, they cannot all be used as energy sources. In addition to energy in all aspects of human necessities, food, housing, and transportation, there are more aspects that rely on plants to provide resources, such as food, wood, cotton, and pasture. . Not all the carbon fixed by plant photosynthesis is stored. The production and decomposition of biomass in nature has constituted a complex balance. Human activities are a link in the entire ecological balance, and it has become a key link. If this link is unbalanced, the demand for more and less compensation will destroy the entire ecological balance, and the consequences will be catastrophic. In fact, due to the increase in population and the inappropriate use of natural resources, the ecological balance has been greatly impacted: forests are declining in a large area, grasses are caused by overgrazing and desertification, and species extinctions are accelerating...

In this way, is there not much as a resource of biomass energy? It cannot be said that the development potential of biomass energy is still great. There are two main aspects: one is the rational use and construction of fuelwood; the other is the utilization of waste as a resource. Let's talk about firewood first, which refers to the leftovers of trees or wood processing that are directly used as fuel. Since humans learned about cooked food, fuelwood has become the main energy source, which has been maintained for tens of thousands of years, and it remained the same until the Industrial Revolution in the 18th century. Because the world was sparsely populated and economically backward, and the development was slow, the use of this energy did not have much impact on the natural ecology. As the energy source of mankind, fuelwood is really indispensable. After the Industrial Revolution, fuelwood alone was not enough for energy. Large-scale industrial production requires huge energy resources as a pillar. Fossil energy has fulfilled this historical mission and has also brought about earth-shaking changes in the economy and society of the entire world. Today, the consumption of fuelwood as an energy source in the world only accounts for about 10% of the total energy. Even so, this ratio is still large, because the base of total energy consumption is astonishingly large, and the absolute amount of 10 percentage points is more than before, which has already posed a threat to forests. The actual ratio is more than this number, because the amount of energy counted by various countries is commercial energy, and cooking and heating in many places, especially in the vast rural areas, are made on-site, which is not included in the statistics at all. Up to now, fuelwood is still an important energy source for rural areas in many developing countries. The ratio of fuelwood to total regional energy consumption is 60% in Africa, 20% in Asia, and 20% in Latin America. Currently, half of the world’s population still uses fuelwood as an energy source for cooking and heating. With the increase of the population, the shortage of fuelwood has become increasingly short. Mankind’s excessive deforestation of natural forests has caused soil erosion and ecological environmental damage, which is tantamount to self-destroying their homes. People have to find new ways out. Among them, the construction of firewood forest is one of the effective ways.

Just as humans cannot rely on wild fruit and hunting for a long time to survive, they must use agriculture and animal husbandry to solve food, so humans cannot rely on deforestation for fuelwood for a long time, and must use production methods to solve fuel. Fortunately, nature provides us with the conditions for production. People can use biomass energy generation methods to create fuelwood forests to obtain fuelwood. Firewood forest refers to artificial forest land for the purpose of obtaining fuelwood. According to the natural conditions of various places, fast-growing, dense planting, high-yield and high calorific value tree species can be selected for construction. This kind of forest land can not only produce fuelwood and charcoal, but also Other forest lands have the same functions as windbreak, sand fixation, soil and water conservation, farmland protection, and ecological improvement, and are also valued by countries all over the world. The United States, Canada, France, South Korea and other countries have begun to implement large-scale fuelwood plantation plans in the 1950s and have achieved significant results. Some tree species have an annual output of fuelwood equivalent to 60 tons of oil per hectare of land, which should not be underestimated. Therefore, where conditions permit, barren mountains, river beaches, and deserts should be used as far as possible to create and utilize fuelwood forests in a planned way.

2 Biogas has become the protagonist of rural energy

Biogas is the final product of organic biomass through a variety of bacterial fermentation under anaerobic conditions. Various organic biomass, such as straw, human and animal manure, weeds, garbage, sewage, industrial organic waste, etc., can be used as raw materials for biogas production. Anaerobic bacteria play a key role in the fermentation process. They are organisms that do not like oxygen in nature. They are particularly active in an oxygen-deficient environment and decompose organic biomass as nutrients. This plays an extremely important role in the ecological balance of nature. People use the characteristics of anaerobic bacteria to produce biogas, which is just right. There are more than one type of anaerobic bacteria. They are usually found in large quantities in the sludge of sewers, manure tanks, swamps and ponds.

| Tips: the composition of biogas The main component of biogas is methane (CH4), which usually accounts for 60% to 70% of the total volume of biogas; the second is carbon dioxide, which accounts for about 25% to 35% of the total volume of biogas; the rest are hydrogen sulfide, nitrogen, hydrogen and carbon monoxide, accounting for About 5% of the total volume of biogas. When methane burns, the flame is blue, with a calorific value of 36,840 kJ/m2, and a maximum temperature of about 1400°C. Due to the different methane content in biogas, the calorific value of biogas is about 20930~25120 kilojoule square meters. Because biogas contains incombustible gases such as carbon dioxide, it has good anti-knock performance and high octane number. |

When using a biogas digester to produce biogas, a suitable temperature is necessary to maintain and enhance the viability of bacteria. Normally, gas can be produced normally within the range of 5~60℃. Within this temperature range, as the fermentation temperature increases, the biogas output can be increased badly. Generally, medium temperature fermentation is used. About 35°C is the most suitable temperature for biogas fermentation, and the gas production is many times higher than normal temperature fermentation. Medium-temperature fermentation consumes a lot of raw materials. In places where there is sufficient raw material and waste heat is available, such as near wine, slaughterhouses, textile factories, and sugar factories, medium-temperature fermentation should be preferred.

Schematic diagram of tank-gas combined fixed biogas digester

Biogas is particularly suitable for production and use in rural areas, and can even develop into a leading role in rural energy. First of all, in terms of the raw materials for biogas production, the raw materials in rural areas are the most abundant. When farmers are engaged in crop production and livestock raising, they can collect livestock manure and human feces, and some crop straws to make biogas. These are the two most basic types. Raw materials. Straws include rice straw, wheat straw, corn stalks, bean vines, melon vines, etc., which are inexhaustible wastes in rural areas. Secondly, the main energy consumption in rural life is cooking and heating. Biogas can take on this task. Usually, a normal temperature biogas digester with a volume of 8 cubic meters produces at least 2 cubic meters of gas per day. The calorific value of the annual gas production is equivalent to 2.5 tons. Firewood can meet the cooking needs of an ordinary farmer. Third, the by-product residues and waste water of biogas are high-quality organic fertilizers, which are also convenient to be applied on farmland. The annual organic fertilizer discharged by ordinary biogas digesters is equivalent to 60-70 kg of fertilizer efficiency, which can meet the needs of 1 to 2 acres (1 acre is about 667 square meters) of farmland, and this type of fertilizer is conducive to improving the soil.

In addition to the use of biogas digesters to produce biogas, it is also possible to collect excess straw in rural areas and use chemical pyrolysis projects to produce gas fuel, which can be used as a supplement and adjustment for rural biogas.

Schematic diagram of straw gasification station

China’s agricultural production produces more than 600 million tons of straw each year, and most of them are not well utilized except for the rural fuel, feed, fertilizer and some industrial raw materials, which consume about 40%. Chemical pyrolysis produces gaseous fuels, and its thermal efficiency is 3 to 4 times higher than that of direct burning of straw, which has attracted more and more attention.

The realization of biogasification of life energy is of great significance. First, it can free up space for rural life to use commercial energy to develop agricultural mechanization, agricultural product processing and rural modernization. Imagine that more than 800 million people in rural areas use coal as a living energy, and it needs 400 million tons each year, which is equivalent to about 20% of the country's total energy consumption. What a huge pressure! In today's world, coal, natural gas, and liquefied petroleum gas have generally entered urban and rural areas as household fuels, but the prices of these fuels have violently risen with the energy crisis. What reason do we have to abandon biogas and chase them? Second, the realization of rural biogasification plays a great role in protecting rural ecology. Each 8 cubic meter biogas digester supplies a family of 4 households with living fuel, and the annual biomass growth of 5 acres of mountain forest is protected based on the annual saving of 2.5 tons of firewood. This is useful for closing hills for afforestation, soil and water conservation, flood prevention and disaster reduction. And so on will play a significant role.

China's promotion of the use of biogas began in the 1950s. By the end of the 20th century, nearly 10 million rural households in the country had used biogas. Many regions have developed ecological agriculture based on the basic model of “pig raising, biogas, food (or fruit, vegetable and tea)”, which not only increased farmers’ income, but also closed the mountains for afforestation. Farmers have tasted the sweetness. In some rural areas, biogas is used for cooking and The heating penetration rate reaches 70%, and the future development is likely to be faster. It is possible that biogas will become the protagonist of rural life energy.

3 Urban waste recycling

Recycling energy from municipal waste is also promising. Urban waste is the waste of people's material life. At present, the average daily production of waste in China is more than 1 kilogram, and the country's annual output is about 200 million tons. Garbage occupies land, besieged cities, and pollutes the environment. There are many harms. The resource utilization, reduction and harmlessness of garbage has become an unavoidable task. The composition of garbage is very complex. As people's material life becomes more colorful, the complexity of garbage is even greater. Nevertheless, the understanding of municipal waste can be simplified. The first is to distinguish between recyclable and difficult-to-recycle garbage, so as to consider sorting out recyclable materials (such as metals, plastics, glass, etc.) in the garbage treatment plant for recycling; secondly, analyzing the calorific value and ash content of the garbage. In order to choose the processing method. Generally speaking, waste with more organic matter has a higher calorific value, which is conducive to the recovery of biomass energy. To realize the "three modernizations" of urban waste, the most important thing is to recycle it. If the recycle is done, the reduction and harmlessness can also be solved. The most conducive way to resource utilization is to recover bio-energy. There are two other treatment methods to choose from-incineration power generation and sanitary landfill recovery of biogas. Both methods have their own adaptability and advantages and need to be determined according to local conditions.

Schematic diagram of household waste incineration power plant

With the popularization of gasification fuels-pipeline gas, liquefied petroleum gas and natural gas as fuels for residents' lives and service industries, coal has gradually withdrawn from the urban fuel stage, the ash content of garbage has been greatly reduced, and the heating value has gradually increased. The incineration method is used to recover the fuel. Energy becomes possible and has economic value. At present, the calorific value of urban waste with high gasification rate is often more than 1500 kcal/kg. In some urban waste, plastic, paper, fabric, wood and other organic matter content account for about 70%, which has a higher calorific value, and it is advantageous to use incineration to generate electricity. Generally, garbage with a calorific value of 1500 kcal/kg can generate about 400 kWh per ton. Assuming that half a ton of garbage is generated per capita each year, more than 200 kilowatt-hours of electricity can be recovered, which is equivalent to half a year of household electricity, which is considerable. The rapid development of municipal waste incineration technology, flue gas purification technology is also becoming more and more perfect, the reduction effect is significant, but also can collect heat, so it has received the attention of countries all over the world. In Europe, the scale of waste incineration tends to be large-scale, and thermal energy is used for both heating and power generation. In Japan, waste disposal has transitioned from landfill to incineration, and the incineration rate has reached 80%, becoming one of the main ways to obtain new energy. In the United States, nearly 200 waste incineration power plants have been built. Many cities in China, including Shenzhen, Guangzhou, Zhuhai, Beijing, and Shanghai, have built waste incineration power plants with very good benefits. However, as far as the whole country is concerned, the proportion of waste treated by incineration for power generation is still very low, less than 5%, and there will be greater development in the future. Of course, not all garbage is suitable for incineration, and garbage with low calorific value is not suitable for incineration, and the efficiency of energy recovery is poor.

Sanitary landfill is also a good way to dispose of waste. The so-called sanitary landfill includes the following four links. The first is to pre-lay a plastic film on the bottom layer to prevent the leakage of dirty water; the second is to stack and re-soil the soil in a planned and layered manner; the third is to lay sewage drainage pipes in the landfill layer to draw out the garbage seepage water, and Special treatment and purification are carried out; the fourth is to bury a biogas collection system to recycle the biogas produced in the waste fermentation process for use as energy. This landfill treatment is a comprehensive application of modern technology. Due to the engineering of landfilling, space can be fully utilized, and floor space can be greatly saved. On average, dozens of tons of garbage can be piled up per square meter of land. After the landfill capacity is full, the site can still be used. From the perspective of energy recovery, the organic biomass in landfill waste is converted into biogas (commonly known as "landfill gas") under anaerobic conditions, which can be collected as fuel or used to generate electricity. After six months of landfilling, gas can be produced. On average, the amount of landfill gas produced per ton of waste is more than that of direct incineration. The landfill will continue to produce gas for 15 years after it is “retired”. The landfill is known as the "Garbage Gas Field". In addition to being used as fuel and power generation, landfill gas can also be purified and used as vehicle fuel to replace gasoline or diesel.

The method of recycling energy from sanitary landfill waste has a successful precedent in China. The Datianshan Waste Landfill in Guangzhou City has begun to draw out landfill gas for power generation, which can generate 20 million kilowatt-hours of electricity every year. The Shenzhen Xiaping Landfill has an average daily disposal of 3,600 tons of waste and an annual output of more than 100 million cubic meters of landfill gas. After full service, the annual gas production will be even more, reaching 300 million cubic meters. The site plans to generate 10,000 kilowatt-hours of installed capacity, while also producing automobile fuel gas. It also reduces greenhouse gas carbon dioxide emissions and concludes external transactions in the form of CDM projects. The practice of recycling landfill disposal waste has broad prospects for development. At present, landfill disposal in China accounts for more than 80% of the total waste, but most of them are simple methods, harmlessness is only a minority, and energy cannot be recycled. If it is gradually transformed into a sanitary landfill and biogas recovery method, the city's nearly 200 million tons of garbage can recover more than 50 billion kilowatt-hours of electricity each year, which is equivalent to more than 20 million tons of standard coal. Wouldn't it be equivalent to an energy rich mine?

The harmless treatment of municipal waste and the recovery of energy, whether it is incineration for power generation or sanitary landfill and recovery of landfill gas, is to be constructed as a project and requires investment and operating costs. Relying on government investment is not enough and not entirely reasonable. This is also one of the important reasons why the garbage has not been properly handled in the past. People must establish the concept that citizens have to take responsibility when discarding garbage, so it is necessary to levy garbage disposal fees. Under this principle, things can be done well by giving full play to the enthusiasm of enterprises to operate waste disposal plants.

4 The right and wrong of ethanol energy

Among biomass energy, there is also an excellent variety called "alcohol energy", which is a type of alcohol that can be used as fuel, the most important of which are ethanol (C2H5OH) and methanol (CH3OH). People are very familiar with ethanol. Ethanol is commonly known as alcohol and has a wide range of uses. It is commonly used in the pharmaceutical and chemical industries and can also be used as a special fuel. In recent years, due to the shortage of oil, people have used ethanol to make ethanol gasoline for vehicles, which is known as “biofuel” to replace part of gasoline. All countries are vigorously promoting ethanol fuel, and the development of ethanol fuel is rapid. Brazil is the world's largest ethanol gasoline for vehicles. A country that produces and consumes gasoline. The ethanol fuel produced in this country has replaced more than 40% of the country's gasoline consumption and is also exported in large quantities. China has no cars using pure gasoline. The consumption of ethanol gasoline in the United States is also not small, reaching 5.6 million in 2000 Tons. China also promoted ethanol gasoline on a large scale in 2004. It should be admitted that the use of ethanol gasoline is an achievement of science and technology, which has enabled mankind to add a means to adjust energy.

However, the traditional method of making ethanol uses grain as a raw material. Many people worry that ethanol will be used in large quantities as a biofuel for automobiles and will compete with people for grain. This worry is understandable and has actually happened. In recent years, the worldwide "food shortage" has caused a stir, and people blamed it on "biofuels." Therefore, the right and wrong of the development of ethanol gasoline must be treated with caution. From the perspective of science and technology, ethanol can be conveniently brewed from grain or from non-grain. We must make ethanol based on the comprehensive utilization of biomass, and prioritize food to meet people's food needs, and it is not appropriate to destroy forests and expand land to grow alcohol-friendly crops. This is a scientific attitude. As a country, it should be like this, and as a world it should also be like this. For some oil-producing countries located in the desert, it is reasonable for them to supply oil to other countries in exchange for food; some food-rich countries are obliged to give priority to food-deficit countries while importing oil. For example, the United States is rich in corn and can supply surplus grain to oil-producing countries. If all corn is used to produce ethanol, it will inevitably reduce exports and exacerbate a worldwide food shortage. Another example is Brazil’s abundance of sugarcane. They use sugarcane as a raw material to brew ethanol, and they will not compete with people for food. This is a good example of comprehensive utilization of biomass. However, driven by economic interests, Brazil has seen a lot of destruction of the Amazon River Basin. Tropical rain forests should be opposed to the widening of land to grow sugar cane. The Amazon rainforest has a vast area and is known as the "lung of the earth". At present, due to various deforestation activities, the area of the rainforest is gradually shrinking, which seriously affects the "living capacity" of the earth. This is worrying.

| Tips: ethanol gasoline Nowadays, ethanol gasoline is used as a biofuel in automobiles, replacing some gasoline. The so-called ethanol gasoline firstly dehydrates ethanol, then adds a "denaturant" to become a "denatured fuel ethanol", and then blends it with a certain amount of gasoline to become a vehicle "acetate gasoline." In general, denatured fuel ethanol accounts for more than 15% of vehicle ethanol gasoline. Ethanol gasoline has the effect of "oxidizer", which can increase the octane number of vehicle fuel, clean the car engine, reduce the replacement of lubricating oil and reduce the harmful content of car exhaust. When promoting aluminum-free gasoline, oxygen-containing compounds such as MTBE and ETBE are often added to gasoline, and ethanol gasoline can be used without these oxygenates, which also avoids pollution. |

How is the comprehensive utilization of biomass to produce ethanol? As long as it is plant biomass containing sugar and cellulose, such as sugar cane, sugar beet, wood stalk, corn stalk, straw, sawdust, etc., it can be used to produce ethanol. Among them, raw materials containing sugar and starch can be directly fermented; raw materials containing cellulose are saccharified by acid hydrolysis or enzymatic hydrolysis, and then fermented to produce ethanol. This approach broadens the way for many biomass utilization, economic benefits are more superior, and ethanol production is likely to be greater. Of course, this ethanol production method is more complicated than the process of using food as raw materials to produce ethanol, but a lot of progress has been made in technology. As for whether or not to use grain raw materials to make ethanol, it depends on the abundance of grain, anyway, it is not the main thing, it is only used as a means to regulate grain production and reserves.

Also worthy of attention is methanol. The production of methanol does not require food at all, and its combustion performance is superior to that of ethanol. However, as a biofuel, methanol is not produced from biomass. Methanol was first used as a by-product in the charcoal production process, and its quantity was very limited. At the beginning of the 20th century, people invented the method of synthesizing H2 and CO through a catalyst under the conditions of high temperature and high pressure, and it was possible to produce methanol on a large scale. From the perspective of producing methanol from biomass, solid biomass such as straw can be gasified to produce synthesis gas H2 and CO, which has attractive development prospects for the synthesis of methanol. We will talk about the manufacture and magical use of methanol later.