main content:

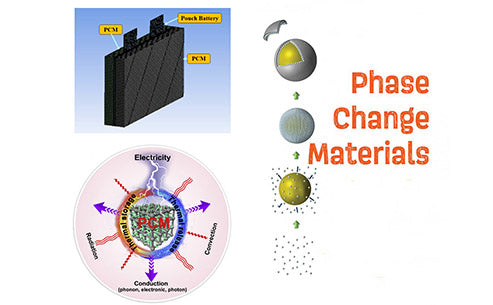

1. Overview of phase change materials

Phase change material (PCM) is a material with unique functions. When it undergoes a phase change at a specific temperature, it can absorb or release a large amount of heat, which is called latent heat. It is precisely because the temperature of PCM remains basically unchanged during phase transition and can absorb or release latent heat that it is used by many researchers as an energy storage material, and can also be used to adjust the temperature of the working environment, so as to achieve phase change temperature control. Due to its advantages of low cost, simple structure and high safety, phase change temperature control technology has been applied in many fields, such as solar energy utilization, waste heat recovery, building energy saving, aerospace, and heat dissipation of electronic devices.

(1) Thermal properties of phase change materials

Phase transition is the process by which a substance changes from one phase to another. According to the thermodynamic classification (Ehrenfest classification), phase transitions are further divided into first-order phase transitions and advanced phase transitions (second-order, third-order, etc.).

When a phase transition occurs, the volume changes, accompanied by endothermic or exothermic heat, and this type of phase transition is called a first-order phase transition. For example, when ice melts, it becomes water of the same temperature, which needs to absorb heat and change its volume, so the conversion between ice and water is a first-order phase transition. When a phase transition occurs, the volume does not change, and there is no endothermic or exothermic heat. The phase transition in which only physical quantities such as thermal expansion coefficient and heat capacity change are called second-order phase transitions, such as the transition between paramagnets and ferromagnets, and the transition between conductors and superconductors. First-order and second-order phase transitions are relatively common, and third-order and higher-order phase transitions are less common.

The phase transition of phase change materials generally used for energy storage and phase change temperature control is a first-order phase transition due to the change of endothermic or exothermic heat and volume. When a first-order phase transition occurs, the substance changes from phase 1 to phase 2. According to the law of phase equilibrium, the chemical potentials of the components are equal, that is, μ1=μ2, but the first-order partial differential quotients of the chemical potentials are not equal, which is expressed by the formula as follows:

Namely,

Therefore, the volume, entropy, and enthalpy of the substance change abruptly during the first-order phase transition:

According to the laws of thermodynamics, the expression for the enthalpy change ΔHtr is:

ΔHtr=TtrΔS=ΔU-PΔV (1-6)

The following conclusions can be drawn from the analysis of the above formula:

(1) When a first-order phase transition occurs, the volume of the system must change;

(2) If the phase change material has the largest latent heat, the system with the largest entropy change should be selected;

(3) The latent heat of phase transition is related to the internal energy change and volume work (PΔV) of the system, and is proportional to the temperature.

(2) Classification of phase change materials

Phase change materials can be divided into organic phase change materials, inorganic phase change materials and composite phase change materials according to their chemical composition.

The main types of inorganic phase change materials are crystalline hydrated salts, molten salts, metals or alloys. Crystal hydrated salts are widely used in medium and low temperature fields, and their cost is relatively low, the melting point is fixed, the latent heat of phase change is large, and the thermal conductivity is generally better than that of organic phase change materials. However, crystalline hydrated salts have the disadvantages of phase separation and easy supercooling. Phase separation is a phenomenon in which inorganic salts and water are separated after multiple phase transitions of crystalline hydrated salts, causing some salts that are incompatible with crystalline water to sink to the bottom and no longer combine with crystalline water, resulting in the phenomenon of phase stratification. The generation of phase separation makes the stability of the phase change material poor, which easily leads to a decrease in energy storage and a shortened service life. In order to solve the problem of phase separation, an anti-phase-separation agent is generally added to the inorganic phase-change material. Commonly used anti-phase-separation agents include crystal structure modifiers, thickeners, and the like. The supercooling phenomenon refers to the phenomenon that the liquid does not solidify when it condenses to the freezing point of the liquid under the pressure, and it needs to reach the temperature below the freezing point to start to solidify. The phenomenon of supercooling is related to the properties, purity and cooling rate of the liquid. The supercooling phenomenon causes the phase transition temperature to fluctuate. Generally, an anti-supercooling agent is added to the liquid to prevent the occurrence of the supercooling phenomenon. At present, crystal water species are often used as inorganic solid-liquid phase energy storage materials.

The main types of organic phase change materials are alcohols, fatty acids, higher aliphatic hydrocarbons, polyhydroxycarbonic acids, polyaldehydes, aromatic ketones, etc. Organic phase change materials generally have the advantages of relatively low cost, good stability, low toxicity, no corrosion, no supercooling and phase separation. However, organic phase change materials also have the disadvantages of low heat storage density and poor thermal conductivity, thus reducing the energy storage efficiency. Since the melting point of organic phase change materials is generally relatively low, most of them are used in the field of medium and low temperature energy storage.

Due to the phenomena of supercooling and phase separation of organic phase change materials, inorganic phase change materials are mostly used in the fields of medium and low temperature phase change energy storage and phase change temperature control. Paraffin in organic phase change materials is widely used due to its low price, stable performance, large latent heat, and non-corrosiveness. Paraffin is a hydrocarbon mixture extracted from petroleum or other mineral oils, and its general chemical formula is CnH2n+2.

2. PCM for battery thermal management

Whether for cylindrical or square power batteries, in battery thermal management systems based on phase change heat transfer media and PCM/OHP, improving the thermal conductivity of PCM and strengthening the heat transfer process inside the PCM are one of the key technologies to reduce the battery temperature and balance the heat distribution of the battery. The current research on battery thermal management, including the Hallaj and Selman team in the United States, the Naterer team in Canada, the Alrashdan team in Jordan, and the Zhang Guoqing team in China, mainly use paraffin as PCM.

As a PCM, paraffin wax has the advantages of high latent heat of phase transition, almost no supercooling phenomenon, good chemical stability, no phase separation and corrosion, but paraffin wax also has the disadvantage of low thermal conductivity. In order to improve the thermal conductivity of paraffin-based PCM, metal particles/powders, metal foams, carbon nanotubes/fibers, expanded graphite/graphene and other highly thermally conductive materials can be added to paraffin wax, and paraffin and other materials can also be coated in other materials to form capsule PCMs with various particle sizes (such as Macro, Micro, Nano). In addition, the volume of PCM generally changes before and after the phase change. To this end, Alrashdan et al. used paraffin/expanded graphite as PCM and analyzed its thermo-mechanical properties in Li-ion battery packs, such as tensile strength, compressive strength, and embrittlement strength. In the work of the above PCM battery thermal management, Khateeb et al. added foamed aluminum to PCM, Mills and Al-Hallaj added expanded graphite to PCM, and Rao and Zhang added natural graphite to PCM, all of which improved the overall thermal management performance of PCM batteries to achieve the unification with the performance of electric vehicles.