Main content:

1. What is a PV breaker

PV breaker can also be called photovoltaic switch(inverter switch), reliability and stability are related to the safe and reliable operation of photovoltaic power distribution system.

2. The main problem of PV breaker

- The high impedance of the contacts causes overheating and even fire.

- The switch cannot be turned off normally, and the switch handle remains in the "OFF" state.

- Not completely cut off, causing sparks.

- Because the allowable operating current is too small, it is easy to cause overheating, which damages the switch interrupter or even deforms the shape.

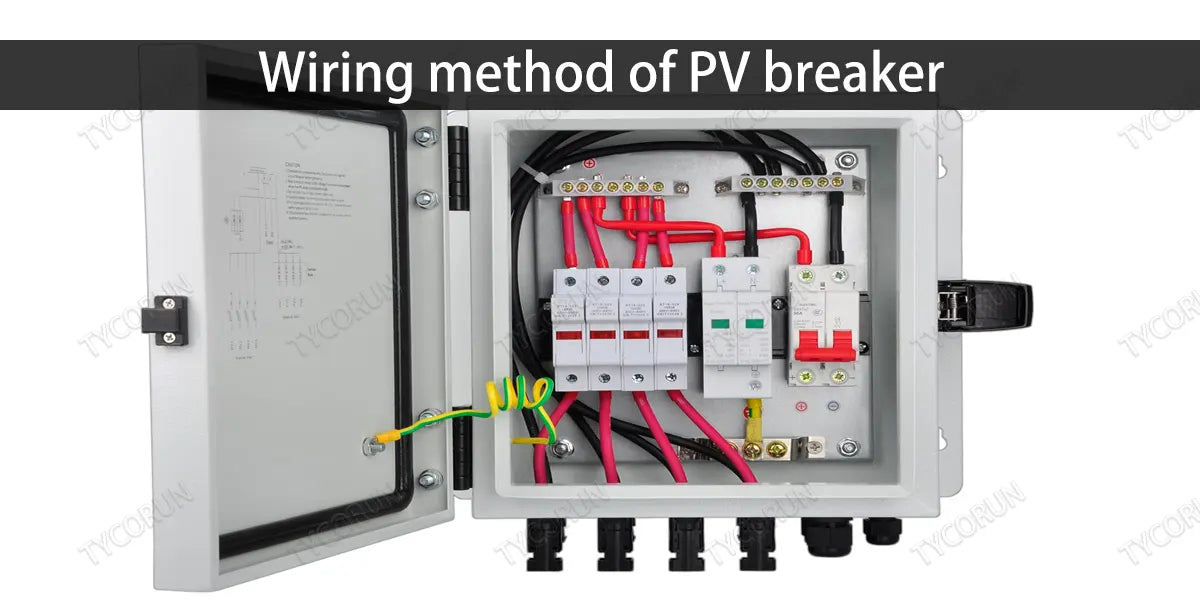

3. Wiring method of PV breaker

The wiring methods of PV breakers include front of the board, behind the board, plug-in type, and drawer type. Front-of-board wiring is a common wiring method.

- Wiring method behind the board

The biggest feature of the rear wiring is that the PV breaker can be replaced or repaired, and there is no need to rewire, only the pre-power supply needs to be disconnected. Due to the special structure, the product has been equipped with special mounting plates, mounting screws and wiring screws according to the design requirements when leaving the company.

Special attention should be paid to the fact that the reliability of the contact of the high capacity circuit breaker will directly affect the normal use of the circuit breaker. Therefore, attention must be paid to the installation and the installation must be carried out in strict accordance with the requirements of the company.

- Plug-in wiring

On the mounting plate of the complete set of devices, first install a mounting seat of a PV breaker, 6 plugs on the mounting seat, and 6 sockets on the connection board of the circuit breaker. There is a connecting plate on the face of the mount or a bolt behind the mount, and the mount is pre-connected to the power cable and load line.

When in use, plug the PV breaker directly into the mount. If the circuit breaker is broken, just pull out the broken one and replace it with a good one. It takes less time to replace than the front and back wiring of the board, and it is convenient.

When installing the plug-in circuit breaker, check whether the plug of the circuit breaker is compressed, and the circuit breaker should be tightened safely to reduce contact resistance and improve reliability.

- Drawer wiring

The inlet and outlet drawers of the PV breaker are rotated clockwise or counterclockwise by the rocker, and the plug-in structure is adopted in the main circuit and the secondary circuit, omitting the necessary isolator for the fixed type.

It realizes the dual use of one machine, improves the economy of use, brings great convenience to operation and maintenance, and increases safety and reliability. In particular, the main circuit contact holder of the drawer holder can be used in common with the contact holder of the NT type fuse.

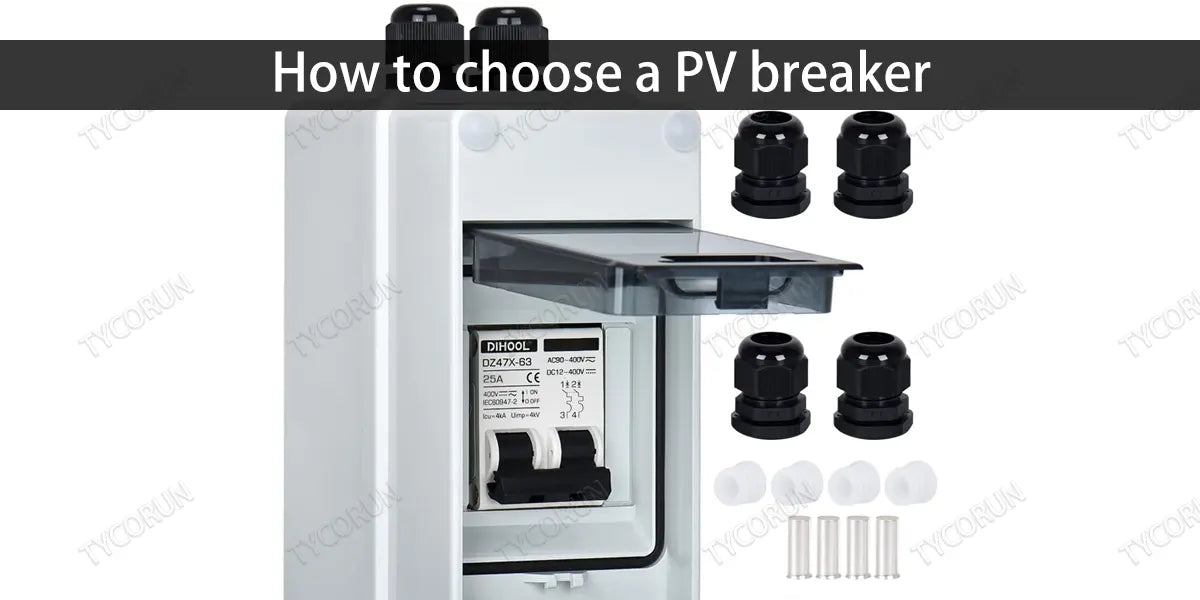

4. How to choose a PV breaker

- Determine the system voltage

The selected PV breaker DC switch provides the maximum voltage required to meet PV system voltage requirements. The common ones are 600V and 1000V. Generally, the system voltage connected to the single-phase inverter is up to 600V, and the system voltage of the three-phase series or power station inverter is up to 1000V.

- Determine the number of separate battery strings

If it is a built-in PV breaker, it is integrated into the inverter, so it is related to the number of MPPTs independent of the inverter. Common inverters are single-channel MPPT, dual-channel MPPT, and there are a few grid-connected inverters with three-channel MPPT on the market.

In general, the inverter power level is designed with a power level of 1000w–3000w inverter as a single-channel MPPT. 3kW-30kW is a two-way MPPT, and a few companies also have a three-way MPPT inverter: large inverters of more than 100kW are generally imported into a MPPT after being merged through the combiner box.

The number of independent MPPTs of the inverter determines the number of independent pass sections of the selected built-in DC switch. If it is an external DC switch, it may be related to the network design of the system. You can choose an external DC switch with multiple panel strings on and off, or an external DC switch that can only turn on and off one string of panels.

- Determine the voltage and current of the battery string

If you have a good understanding of the structure of the PV inverter, especially when the solar inverter company chooses the built-in DC switch. In order to effectively save the cost of the inverter, it can be selected by studying the input and output DC voltage and current curves of the inverter.

Ensure that the selected DC switching curve envelops the DC switching and current curves of the inverter input in various weather environments and temperatures.

- Analyze the environment used and how it is installed

According to the use of the environment to determine the working temperature, protection and fire rating, generally good quality DC switch work stably can be -40 ° to 60 °.

The protection level of the external DC switch of the common PV breaker is IP65, and the built-in DC switch is installed to ensure that the whole machine passes IP65. The fire rating is generally UL94V-0 for the shell or body material, and UL94V-2 for the handle. Installation methods include panel mounting, base mounting, single hole mounting, etc.

- Determine the specific model

If you meet the above conditions, you will need to select a specific model from the preferred brand. Generally, the specifications of specific models are segmented by current, and it is difficult to find a perfectly matched DC switch.

Generally, there is a certain margin to select a DC switch that is higher than the theoretically calculated specification. Common are 16A, 25A and 32A, and some large companies will have rated voltage levels of 40A, 50A, 600V or 1000V.

5. PV breaker and power station safety

The safety of photovoltaic power plants is the basis for investors to obtain income, and the frequent failure of photovoltaic power stations is closely related to equipment selection. In general, many people tend to pay more attention to the quality of "large" equipment, such as photovoltaic modules and inverters when selecting equipment.

Small components such as PV breakers and junction boxes are often overlooked, but they are responsible for the safe operation of photovoltaic power plants. The proportion of PV breaker in the whole system investment is about 0.1%-0.2%, which can be said to be the "small and transparent" power station system in terms of cost.

In terms of function, although it is not directly involved in the power generation process like modules and power inverter 2000 equipment, it can cut off the circuit in time when the line has a short circuit and other faults, which can be called the security system of the photovoltaic power station.

The special part of photovoltaic power generation is the conversion of DC and AC through the inverter, so it is necessary to use different circuit breaker products on the AC side and DC side.

On the contrary, when AC circuit breakers are used on the DC side, the arc extinguishing capacity and rated load cut-off power of these AC switches are far from enough, which can easily lead to overheating, leakage and sparks.

The working voltage of the PV breaker is relatively high, the DC current has no zero point, and the arc extinguishing segmentation of the DC system is more difficult than that of the AC system. This leads to the situation that the PV breaker is not easy to segment when the arc is pulled into sections, and if the fault is not removed in time, a slight delay in time may cause a fire.

The DC circuit breaker has different arc extinguishing covers and arc extinguishing chambers, and the arc extinguishing capacity is higher than that of AC circuit breaker products.

From large-scale ground power stations to distributed power stations, the technical parameters of PV breaker products are transformed from large to small. In terms of product characteristics, products have their own focus on design for different application environments.

Large-scale power stations are usually distributed in the northwest region, and the harsh environment of large temperature differences between day and night, large wind and sand, and high altitude will accelerate the aging of PV breakers. This requires PV breakers to continuously improve their ability to adapt to the environment and resist interference.

6. Conclusion

With the clarification of China's photovoltaic policy, the number of new photovoltaic power plant installations has increased year by year. Especially with the current launch of distributed photovoltaic systems, the installation of rooftop photovoltaic systems for individual households will become more and more popular.

The PV breaker will be the most important component of the safety guarantee of these systems, and the reliability and stability of the photovoltaic DC switch are directly related to the stable power generation and income of the photovoltaic system. It directly affects the safe and reliable operation of the photovoltaic system, so it will be crucial to choose a qualified PV breaker.

Related articles: photovoltaic module manufacturers, photovoltaic power station, AC coupling vs DC coupling