Hybrid vehicle technology has become one of the focuses of the development of the automotive industry. The Prius, a hybrid sedan launched by Toyota Motor Corporation in 1997, has been developed to the fifth generation, with a fuel-saving rate of more than 50%. The IMA hybrid system introduced by Honda Motor Company has been successfully applied to models such as Civic and Insight. General Motors' two-mode deep hybrid SUV represented by the Escalade is very popular. Cumulative sales of Ford Motor Company's Escape and Mariner hybrid SUVs also topped 100,000. In the structure and technology of hybrid vehicle products, high voltage, high speed, integration and deep hybrid are the mainstream development trends. In terms of hybrid mode, it is developed from series or parallel mode to hybrid mode, and transition from transmission coupling and clutch coupling to planetary gear coupling. In terms of mixing degree, with the advancement of battery technology, the mixing degree has been further improved, and the conversion from petroleum energy to electrical energy has been gradually realized.

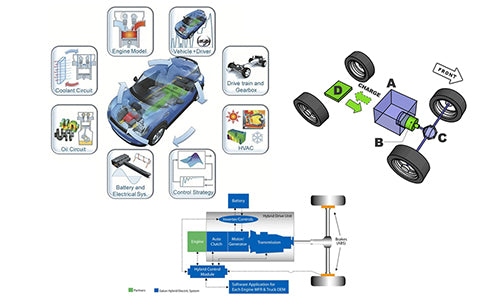

Structure of hybrid vehicle

After years of development, the hybrid electric bus technology has experienced the development process from series to parallel to hybrid, such as the early series system of Toyota Coaster in Japan, the HMR parallel system of Hino, the parallel system of Eaton of the United States, and the parallel system of General Motors of the United States. The hybrid system, the hybrid system of the European BAE Systems company, etc., are all representative products. In the hybrid system, the plan of BAE Systems is to use a planetary gear mechanism and a clutch to realize a variety of working modes by controlling the working states of the clutch, brake and two motors; the hybrid plan of General Motors uses two sets or three. A set of planetary gear mechanism and two motors, through the control of the clutch and the motor, realizes the working state switching and shifting of the hybrid power system. China's hybrid bus technology started from the national "Ninth Five-Year Plan". After fifteen years of development, great progress has been made in the development of hybrid buses. Zhongtong, Yutong, Huanghai and other enterprises have developed hybrid passenger car prototypes and trial-run products. The hybrid system of FAW Bus adopts a dual-shaft parallel structure; Shenzhen Wuzhoulong adopts a single-shaft dual-clutch hybrid structure powertrain and a single-shaft dual-motor hybrid structure, which belong to the hybrid and clutch coupling mode. By controlling the working state of the clutch, the realization of Conversion between series working conditions and parallel working conditions; CSR Times adopts a similar solution to BAE systems; Xiangtan Electric Company, Xiamen Golden Travel and Dandong Huanghai realize the conversion between series working conditions and parallel working conditions through clutches.

Hybrid bus

Now the most widely used hybrid vehicles are nickel-metal hydride batteries and lithium-ion batteries, of which lithium-ion batteries have greater advantages, and many countries are competing to invest huge amounts of money to develop lithium-ion power battery technology. At present, there are more than 20 large-scale enterprises producing lithium-ion batteries for automobiles in the world. Johnson Controls, LG Chem, Toshiba, Hitachi, NEC and other companies have successively developed and produced lithium-ion battery systems for electric vehicles. China's new energy vehicle battery manufacturers mainly include Mengli, Lishen, Xingheng, Wanxiang, BYD, AVIC Lithium, BAK, etc. These companies have built lithium-ion power battery production lines and carried out mass production and Loading and running.

Hybrid car battery

In recent years, the permanent magnetization of vehicle drive motors has become one of the industry's consensus and realistic choices. Among the main models, almost all hybrid cars use permanent magnet synchronous motors, and pure electric cars with lithium-ion batteries also basically use permanent magnet synchronous motors. At present, the permanent magnet synchronous motor for vehicles covers the power range of 9~90kW, matching all types of hybrid vehicles such as mild-hybrid, medium-hybrid, and heavy-hybrid vehicles, as well as pure electric vehicles. At present, there are four main control strategies, logic threshold control strategy, instantaneous optimization control strategy, global optimization control strategy and intelligent control strategy, among which the logic threshold control strategy has been applied in the actual commercialized hybrid vehicle. The most practical research involves the rule-based control strategy, which has the advantage of high execution efficiency, but cannot guarantee the best matching of the energy flow in the vehicle. Control strategies based on judgment rules are divided into two types: thermostat control strategy and power following control strategy. Both have their own characteristics, and the development trend is to combine the two. Other control strategies are still in the research stage. The optimization research of control strategy is divided into two categories: one is the optimization of control parameters, and the other is the optimization of power system efficiency.

Permanent Magnet Synchronous Motor